Gear-rack transmission type horizontal three-cylinder plunger reciprocating pump

A technology of rack and pinion, reciprocating pump, applied in multi-cylinder pump, piston pump, variable capacity pump components, etc., can solve the problems of increasing development difficulty, unstable starting of linear motor, and inability of linear motor to adapt to the working environment, etc. The effect of constant flow, small flow and pressure pulsations, and rapid reversal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

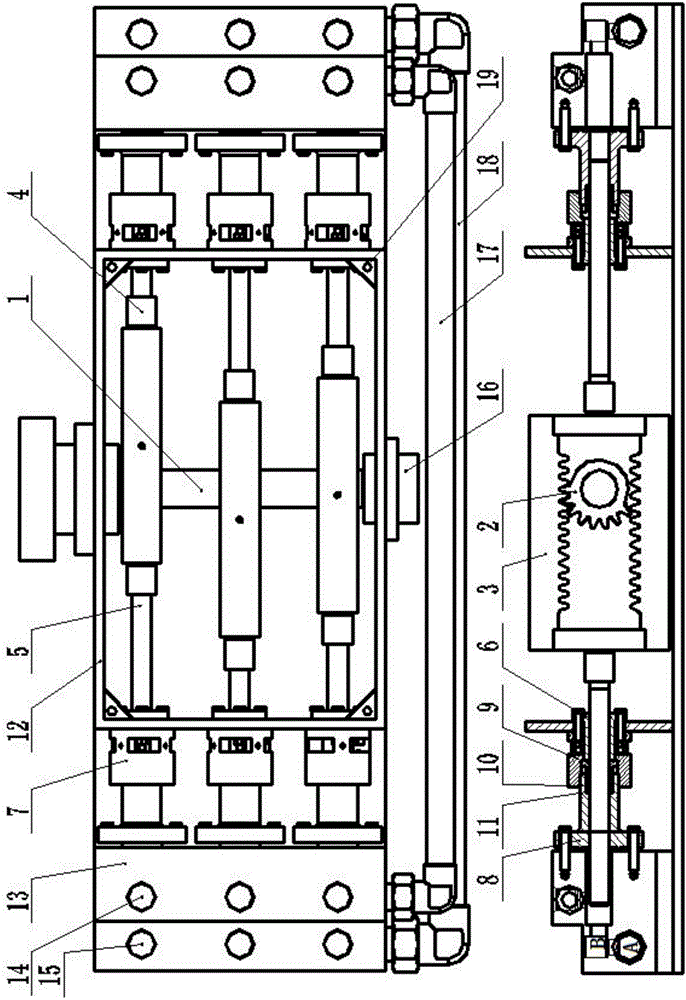

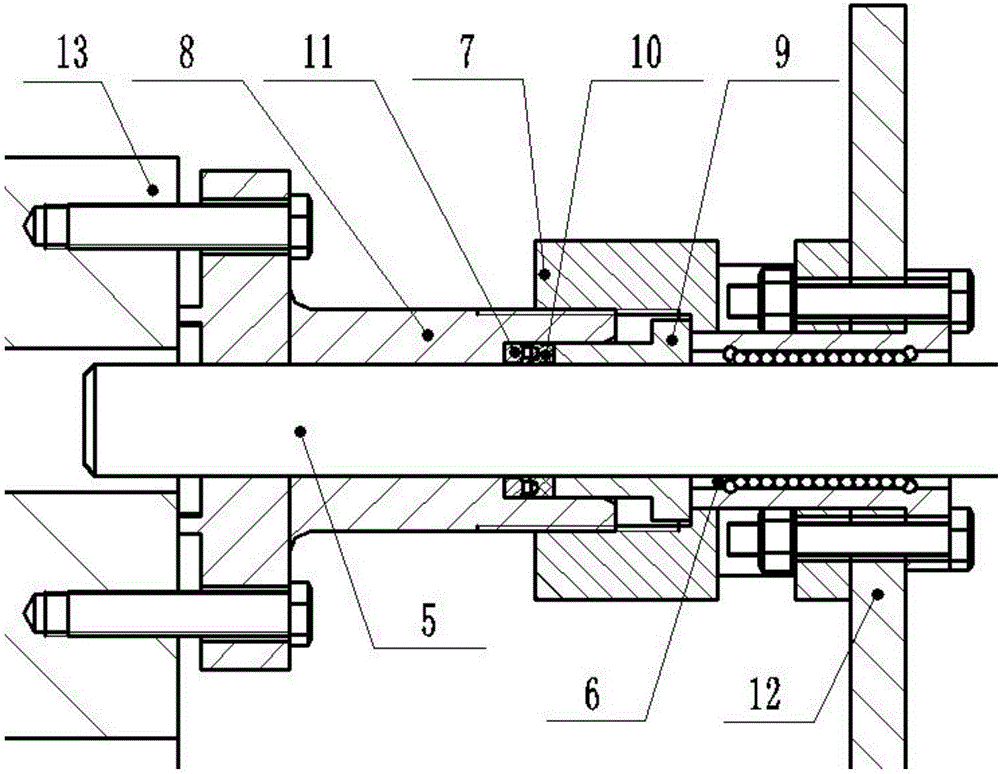

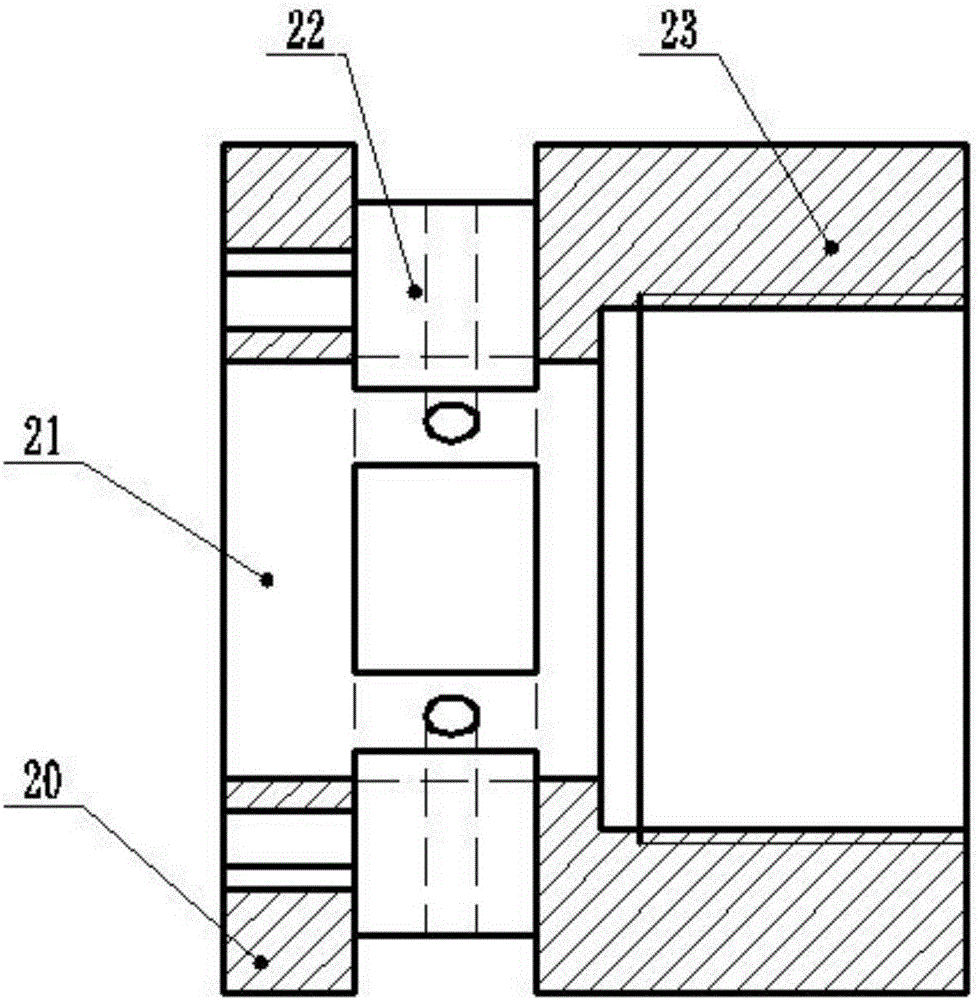

[0031] like figure 1 As shown, a new horizontal three-cylinder plunger reciprocating pump driven by rack and pinion, the gear shaft (1) is connected with the power machine, and the power is transmitted to the main shaft. Under the support of the bearing seat (16), the main shaft drives the three pairs of non-full gears (2) on it to perform uniform rotation in a single direction, and the rack (3) is driven by the non-full gear (2) to perform regular uniform speed Linear reciprocating motion, and quick reversing. The rack (3) is directly connected to the plunger (5) through the connecting ring (4). The uniform linear reciprocating motion of the plunger (5) cooperates with the plunger cylinder (8), and one end sucks in while the other end discharges liquid. One end of the plunger cylinder (8) is connected to the valve body (13) through its own flange and bolts, and the other end is connected to the special gland plate (7) through thread fit, and the linear bearing is inserted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com