Four stroke injection valve

An injection valve, four-stroke technology, applied in fuel injection devices, charging systems, machines/engines, etc., can solve problems such as thermal efficiency and fuel consumption rate reduction, spray characteristic injection hole deviation, increase compression ratio, etc., to prolong life , Improve wear resistance and prevent decarburization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, the present invention will be described in more detail with reference to the drawings.

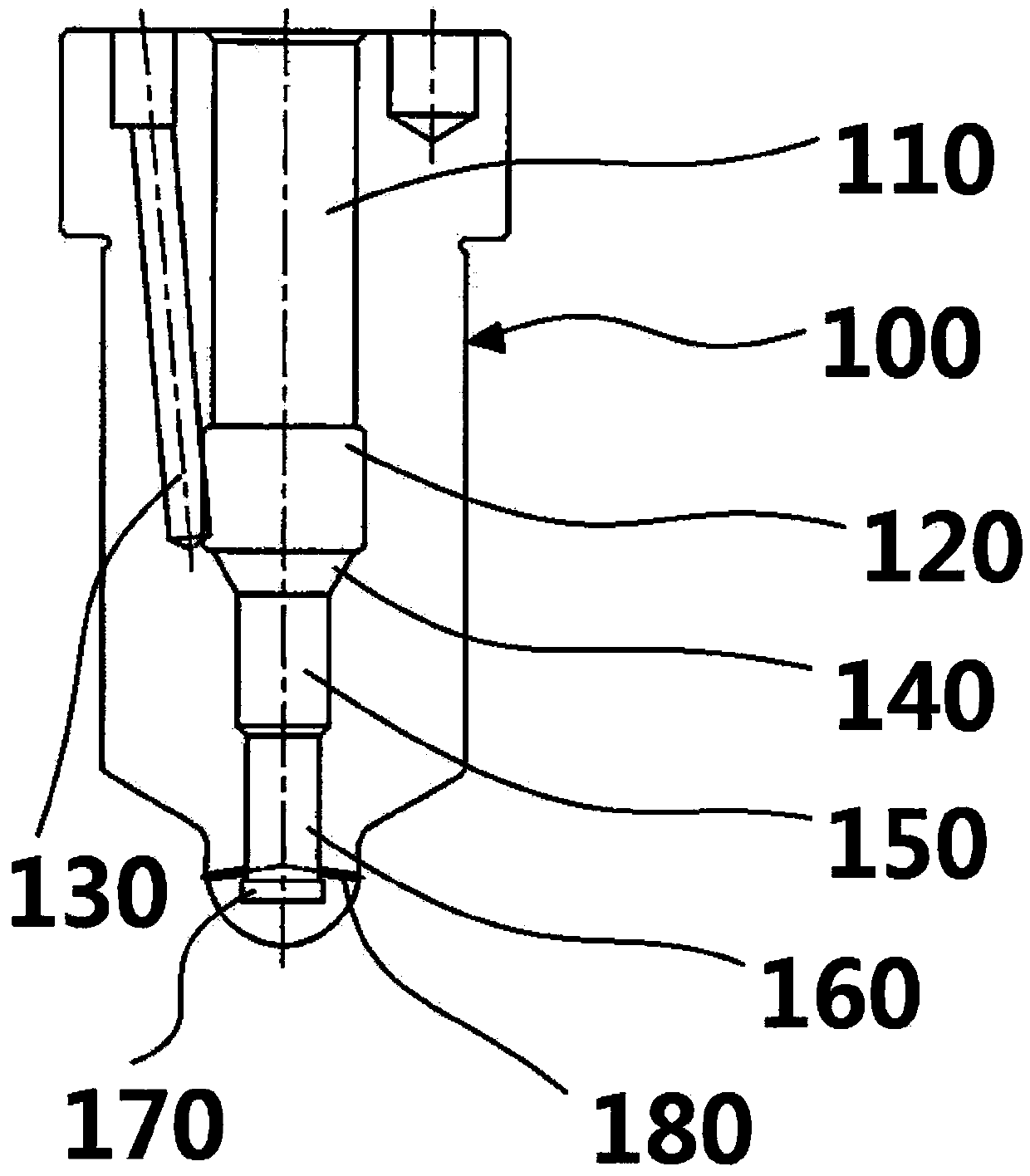

[0037] image 3 It is a drawing showing a stamped retainer of a four-stroke injection valve according to a first embodiment of the present invention.

[0038] The injection valve according to the present invention includes: a stamped cage 100 formed with a punch rod 200 (refer to Figure 4 ) sliding hole; punch rod 200 (refer to Figure 4 ), is inserted into the slide hole and slides to control fuel injection.

[0039] The sliding holes formed in the stamped cage 100 are constituted in order from the upper part: a base sliding hole 110 having a first diameter, a first fuel chamber 120 having a second diameter larger than the first diameter, and the first fuel chamber 120 being further away from the first fuel chamber 120. The tapered first opening and closing surface 140 with the smaller diameter, the second fuel chamber 150 having a third diameter smaller than the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com