Pressure auto-balancing anti-high-pressure water gushing air bag

A self-balancing, water pressure balancing technology, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve problems such as limited height of water retaining plate, poor protection effect, equipment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

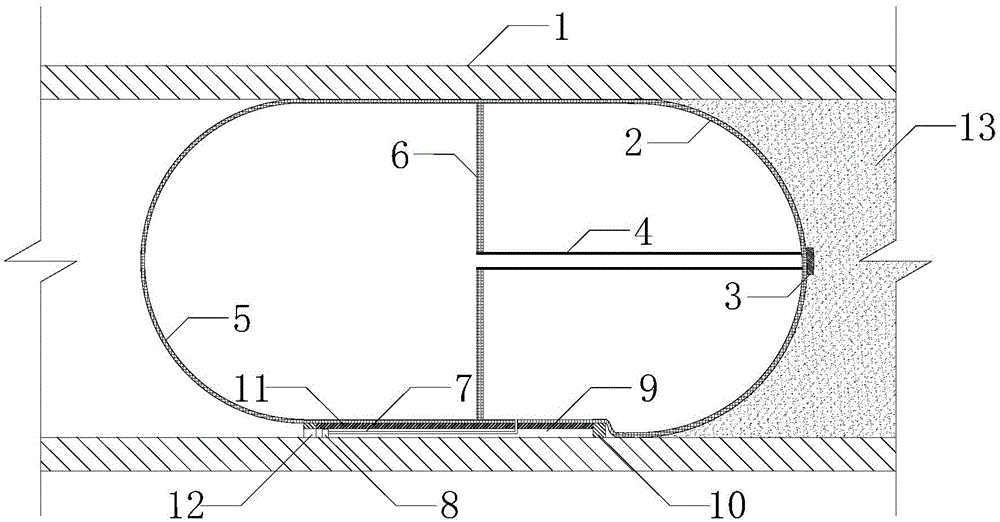

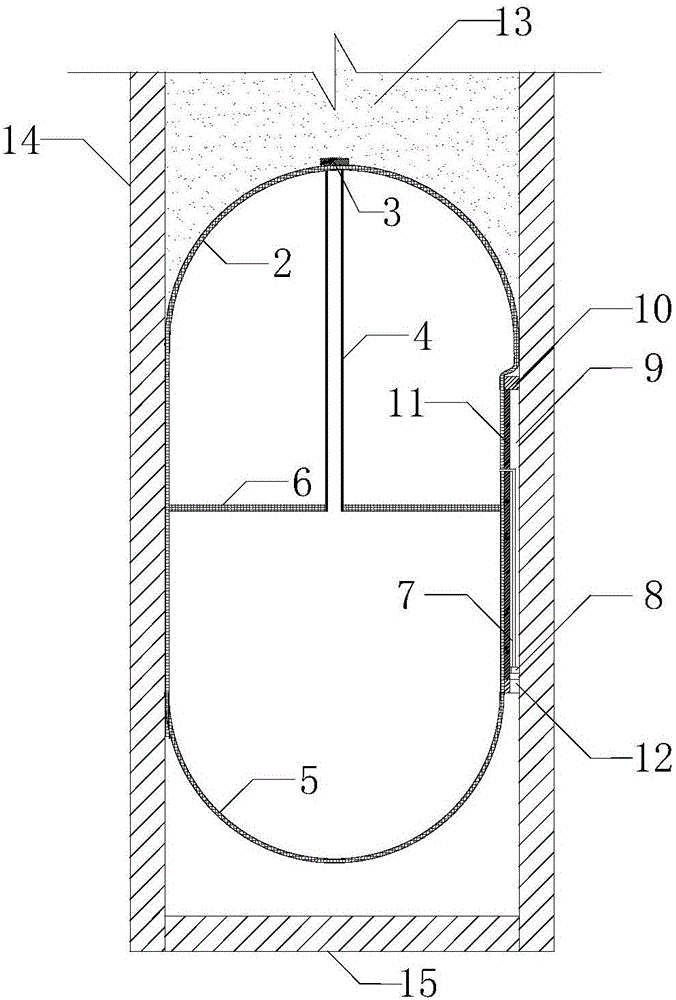

[0031] A pressure self-balancing tunnel or shaft anti-high pressure water surge air bag, its structure is as follows figure 1 or 2, including:

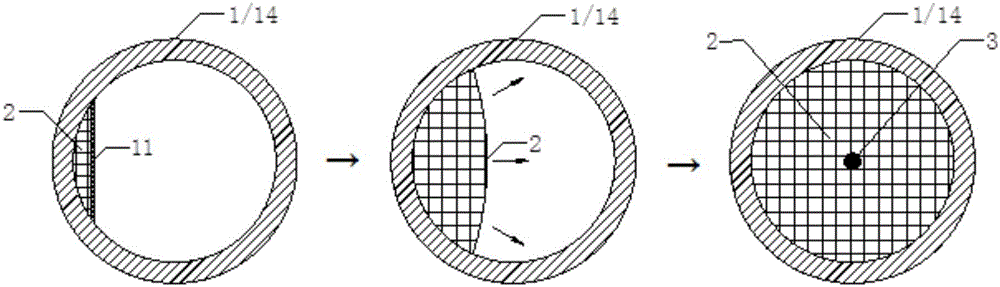

[0032] Airbag main body: its interior is divided into elastic airbag 2 and water pressure balance bag 5 by partition plate 6, two independent parts, elastic airbag 2 is also provided with pressure relief pipe 4, one end of pressure relief pipe 4 passes through partition plate 6 and Connect the water pressure balance bag 5, and the other end stretches out the side of the elastic air bag 2 facing the high-pressure gushing water 13, and adopts the pressure relief plug 3 to seal. Such as Figure 4 As shown, the main body of the airbag is a three-layer composite material, the inner layer is an elastic rubber layer 16, the middle layer is a protective fiber layer 17 with a metal mesh, and the outer layer is a braided fiber layer 18 with tiny protrusions on the surface. Such as Figure 5 As shown, the pressure relief plug 3 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com