Pneumatic drill horizontal well annulus cuttings simulation device

A simulation device and horizontal well technology, which is applied in the direction of earthwork drilling, wellbore/well components, etc., and can solve problems such as high resistance, stuck pipe, high torque of the drill string, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

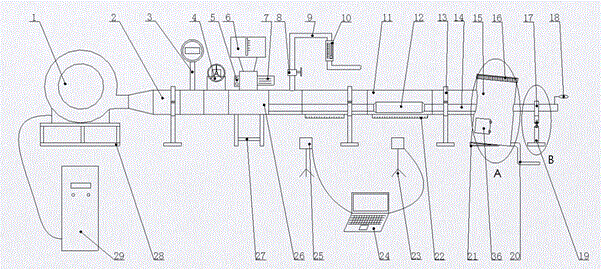

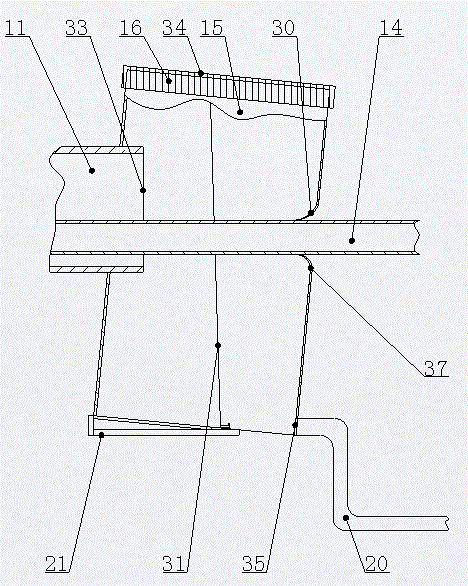

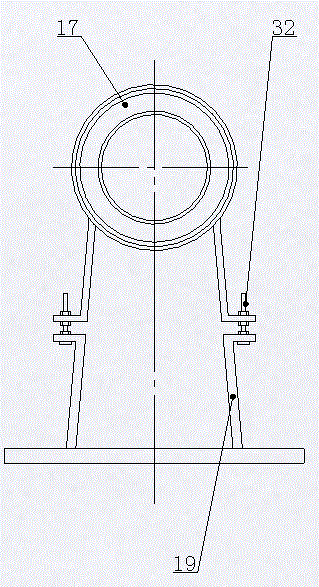

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] Such as Figure 1~3 As shown, an air-drilling horizontal well annular rock-carrying simulation device includes a gas supply part, a cuttings supply part, a downhole annular space simulation part, a water supply part, a separation recovery part and a data acquisition part. It is characterized in that: the air supply part is composed of a fan 1, a steel pipe 2, a vortex flowmeter 3 and a butterfly valve 4 connected in sequence, and the cuttings supply part is composed of a sand storage tank 6, a rotary valve 7, a frequency converter 5, and an acceleration chamber 26 and the feeding support 27 are composed from top to bottom, and the downhole annulus simulation part is composed of glass pipe 11, PVC pipe 14, PVC drill pipe joint 12, rolling bearing 17, rotating handle 18, adjusting bolt 32, rubber curtain 30, pipe The bracket 13 and the adjustable bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com