Downhole device for pumping well

A technology for pumping wells and suits, which is applied in wellbore/well components, sealing/package, earthwork drilling and production, etc. It can solve the problems of well site pollution and function as usual, so as to reduce operating links, shorten operating hours, and save oil production The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

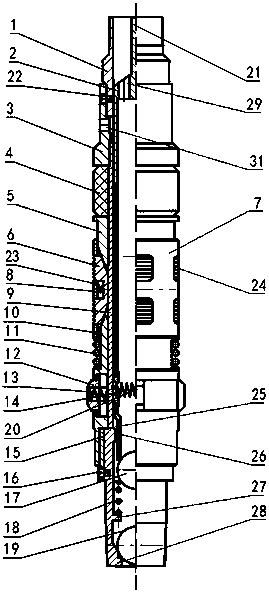

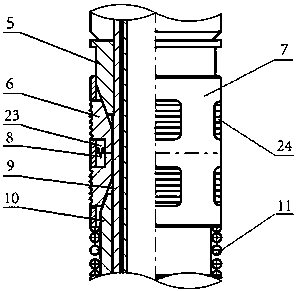

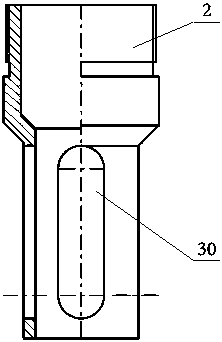

[0018] Below with the present invention as figure 1 The optimization scheme shown is taken as an example to further illustrate the technical scheme of the present invention.

[0019] The transition joint 1 at the top of the device of the present invention is fixedly connected with the lower end of the oil well pump, and sent into the well together with the oil extraction string. After reaching the predetermined position, the oil extraction string is rotated to transmit the torque power from the transition joint 1 through the upper joint 3, The central tube 9 is transferred to the helical sleeve 15 to drive the helical sleeve 15 to rotate. Since the helical sleeve 15 is threadedly connected to the lower cone 10, the relative rotation between the helical sleeve 15 and the lower cone 10 makes the lower cone 10 has an upward displacement relative to the central tube 9, and the tooth block 6 is squeezed by the upper cone 5 and the lower cone 10 through the upper and lower slopes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com