Steel sleeve for full sleeve working method for actively transporting waste and construction method thereof

A technology for steel casing and slag transport, applied in casing, earthwork drilling, drilling equipment and methods, etc., can solve the problems of difficulty in controlling pile quality, low efficiency and safety, restricting construction methods, etc. The effect of surface soil settlement, saving construction time and cost, and preventing the collapse of the hole wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

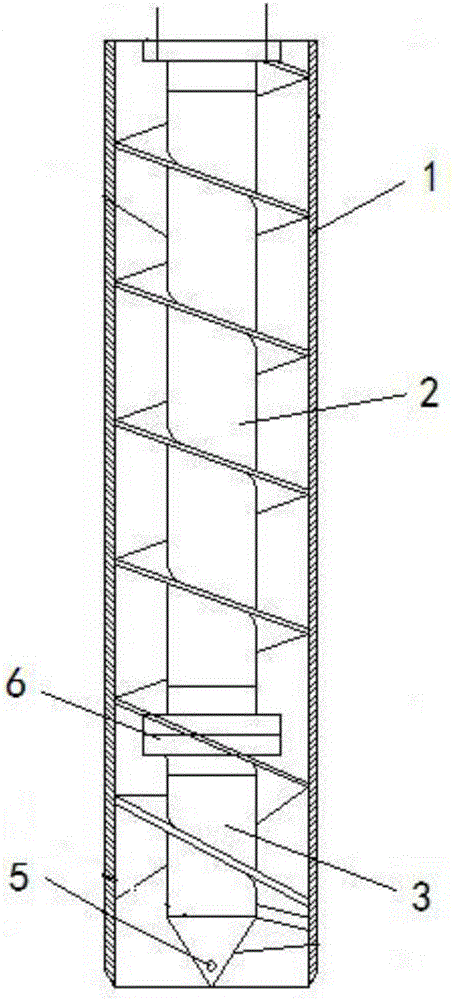

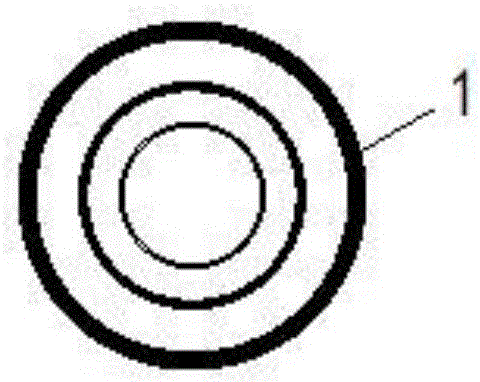

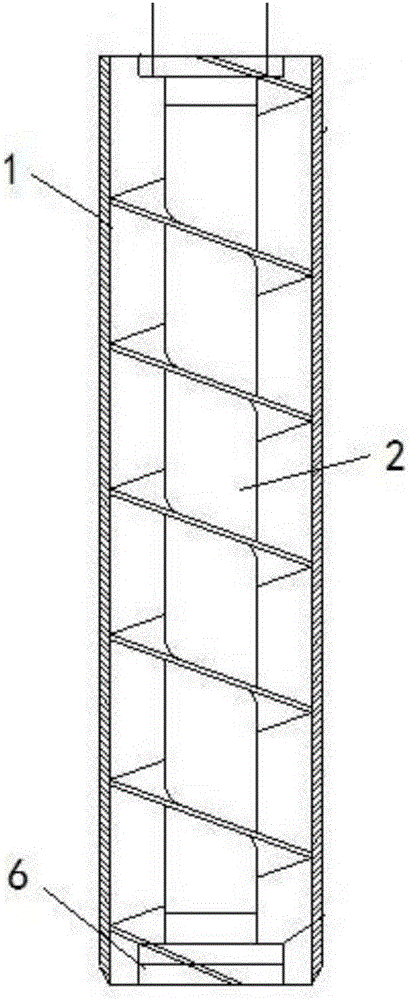

[0036] Such as Figure 1 to Figure 6 As shown, a steel casing for a full casing pipe construction method capable of actively transporting slag of the present invention includes several steel casing pipes 1, auger rods 2 and drill bits 3 for digging, and several auger rods 2 from bottom to top Sequential axial connection, and penetrates through the steel casing 1 sequentially axially connected from bottom to top along its axial direction, wherein, the steel casing 1 sequentially connected axially from bottom to top includes steel casing for excavation, standard layer steel casing Casing and steel casing for slag discharge. The uppermost steel casing 1 is provided with a slag discharge port 4. The drill bit 3 is installed on the lowermost spiral drill pipe 2. The bottom of the drill bit 3 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com