Connecting device for frame sheet modules of vertical circulating stereoscopic garage frame sheets

A three-dimensional garage and vertical circulation technology, which is applied in the field of garage accessories, can solve the problems of unfavorable three-dimensional garage transformation and maintenance, manufacturing difficulty and high manufacturing cost, and difficulty in increasing the height of the three-dimensional garage, so as to facilitate the transformation, production and assembly process Simple, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

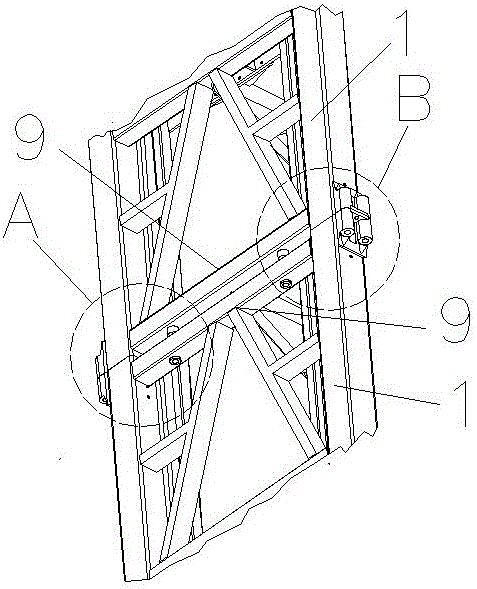

[0031] Example 1. Such as Figure 1 to Figure 4 As shown, the connecting device of the frame module of the vertical cycle three-dimensional garage frame frame, the connecting device includes a pair of connecting assemblies with the same structure, a positioning bolt 5, and two connecting bolts 6, and the two connecting assemblies are respectively located in two required On the butt side of the butt ends of the vertically butt-jointed frame modules, each connecting assembly includes two connecting cylinders 2 whose central axis is perpendicular to the connecting surface connected by the positioning connector 3, and the positioning connector 3 is provided with a central axis vertical In the positioning hole 4 of the connecting surface, the positioning hole 4 of the positioning connector 3 of the two connecting components is connected by a positioning bolt 5 , and the corresponding connecting cylinders 2 of the two connecting components are connected by a connecting bolt 6 .

[...

Embodiment 2

[0046] Example 2. The difference between this embodiment and Embodiment 1 is that two connecting cylinders 2 are fixed on a connecting plate 10 . The connecting plate 10 is vertically provided with two grooves 7 , and a connecting cylinder 2 is fixedly connected to each groove 7 . The connection assembly is a forged or cast unitary part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com