Concrete simply-supported beam based on carbon fiber grid composite boards and manufacturing method

A composite plate and manufacturing method technology, applied in the direction of joists, girders, trusses, etc., can solve the problems of insufficient bearing capacity of carbon fiber materials, peeling damage, poor fire resistance and high temperature resistance, etc., to improve construction efficiency, The effect of preventing peeling damage and improving fire resistance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

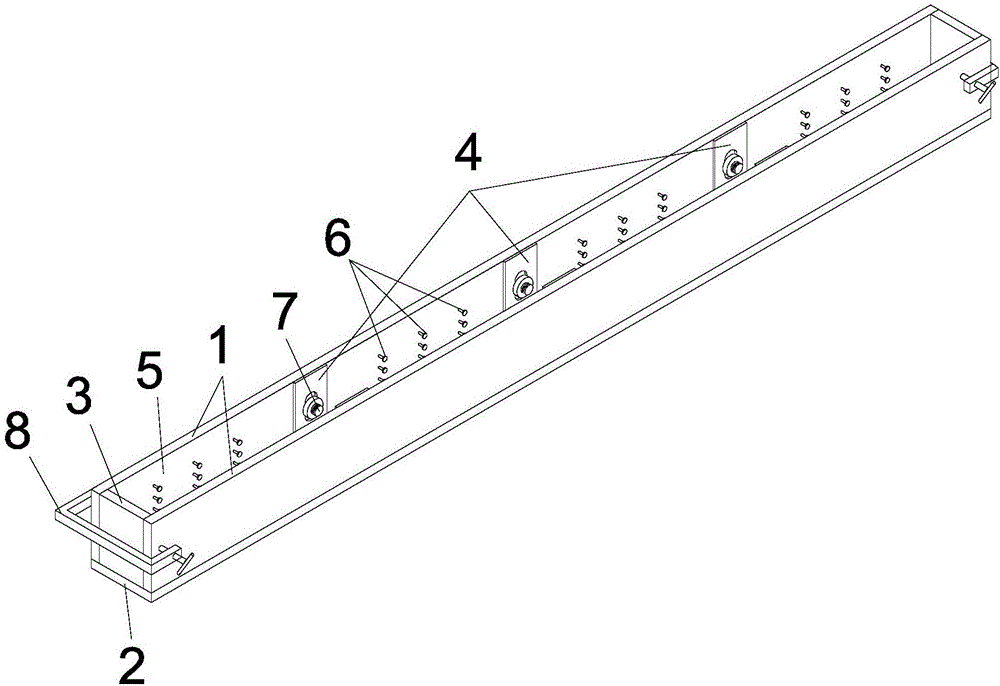

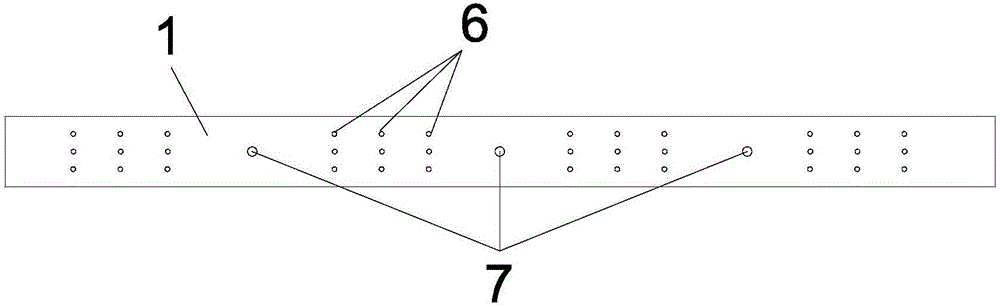

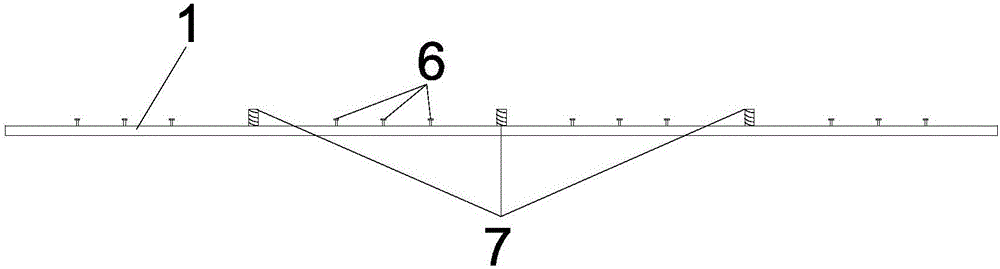

[0023] The technical scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0024] 1. Place the mold accurately;

[0025] 2. Place the multi-layer carbon fiber grid cloth on the mold, and put a positioning strip of specific thickness between the bottom grid cloth and the bottom of the board, between each layer of grid cloth, and the top grid cloth;

[0026] 3. Prestress the carbon fiber mesh cloth through the tension device;

[0027] 4. Insert shear-resistant chopped steel carbon fiber into the pores of each layer of carbon fiber mesh cloth;

[0028] 5. Prepare the steel carbon fiber reinforced cement matrix and pour it on the top layer of carbon fiber mesh cloth, fully vibrate it to penetrate into the bottom of the board and the pores of each layer of carbon fiber cloth;

[0029] 6. Smooth the cement-based mortar on the top of the board to make the thickness consistent with the positioning bar on the top of the board;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com