Prefabricated steel frame infill wall system with resettable rigid connection and its construction method

A rigid connection and rigid connection technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of poor seismic performance, inability to connect, and the weight of filling walls, to ensure construction efficiency, easy assembly and connection, and easy repair. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

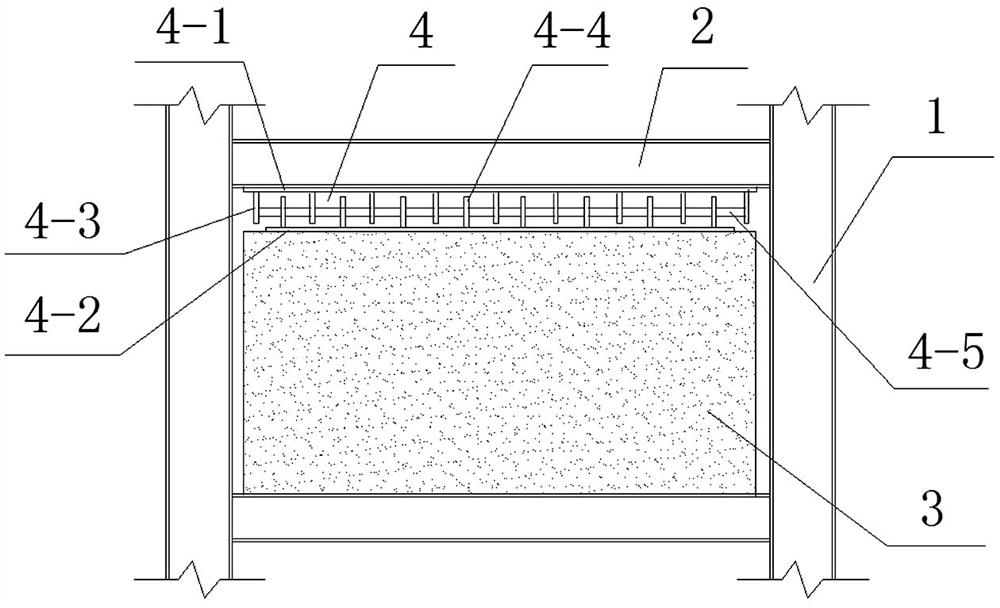

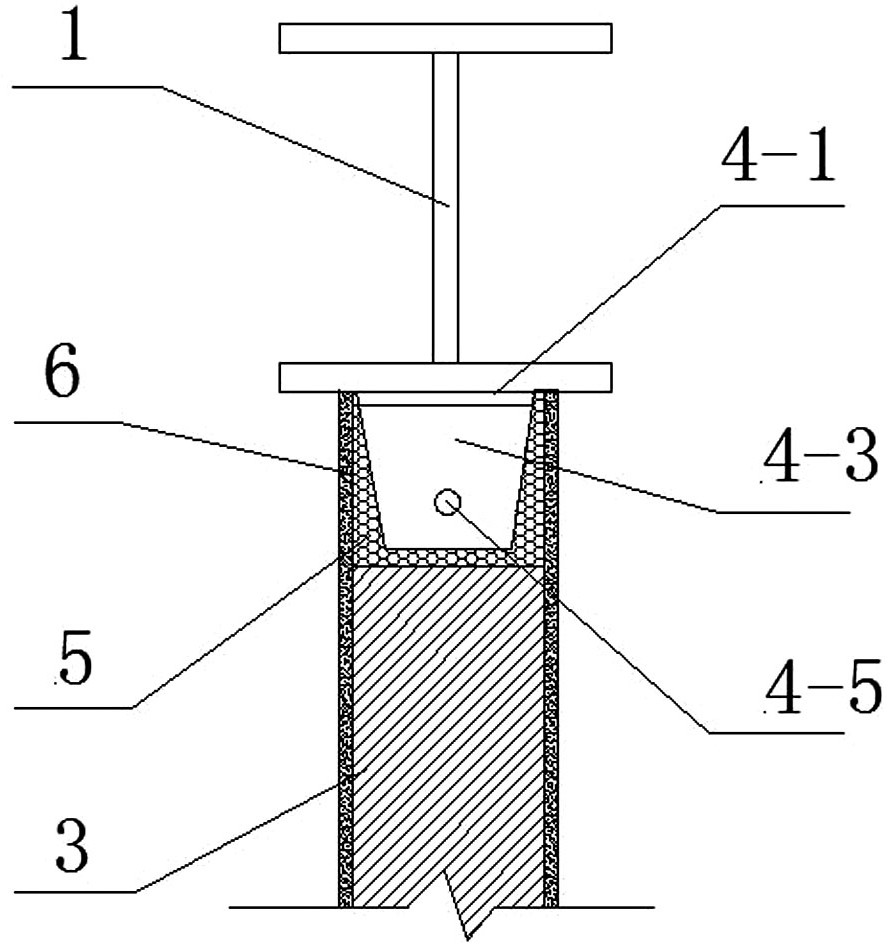

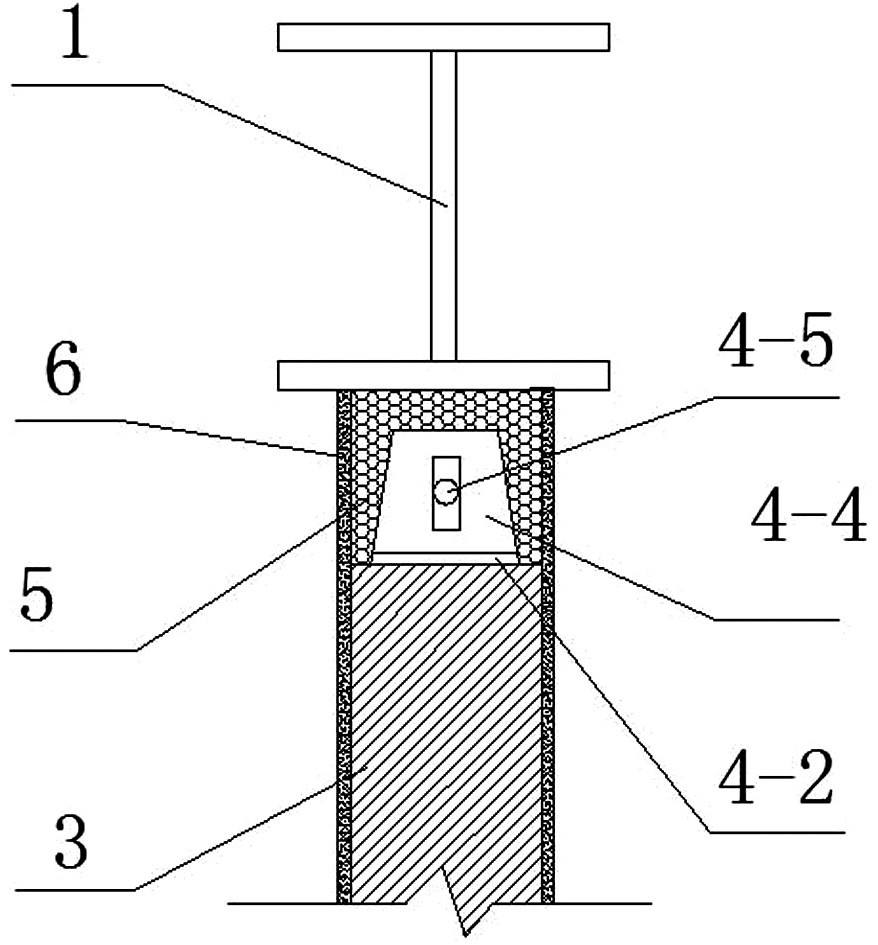

[0050] Examples see figure 1 , Image 6 , Figure 7 As shown, this prefabricated steel frame infill wall system includes steel frame columns 1 , steel frame beams 2 , prefabricated infill wall panels 3 , resettable rigid connectors 4 , flexible materials 5 , and plastering layers 6 .

[0051] see figure 1As shown, this prefabricated steel frame infill wall system with resettable rigid connection includes a rectangular steel frame surrounded by steel frame columns 1 and steel frame beams 2 and a prefabricated infill wall panel 3 filled in the steel frame. The upper end of the prefabricated infill wall panel 3 is connected to the upper steel frame beam 2 through a resettable rigid connector 4, and the lower end is welded and fixed to the lower steel frame beam 2; there is no connection between the prefabricated infill wall panel 3 and the left and right steel frame columns 1 , The gap distance between the two is 20mm ~ 30mm. see Image 6 As shown, the gaps between the prefa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com