Construction method of assembling type building provided with hidden beams

A construction method and an assembled technology, which can be applied to buildings, building components, building materials, etc., can solve the problems of inability to further shorten the construction period and many processes, so as to improve the strength of assembly and connection, reduce construction pollution, and reduce on-site construction steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

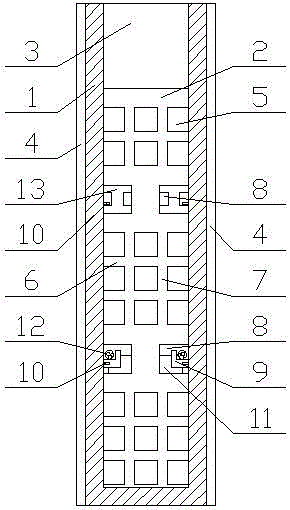

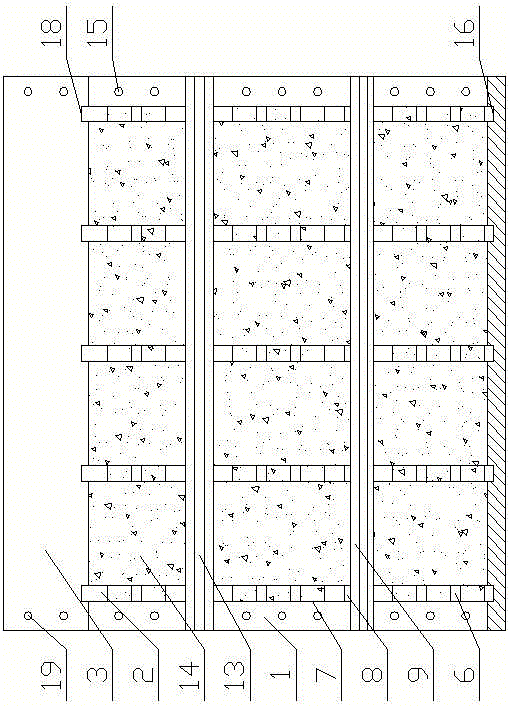

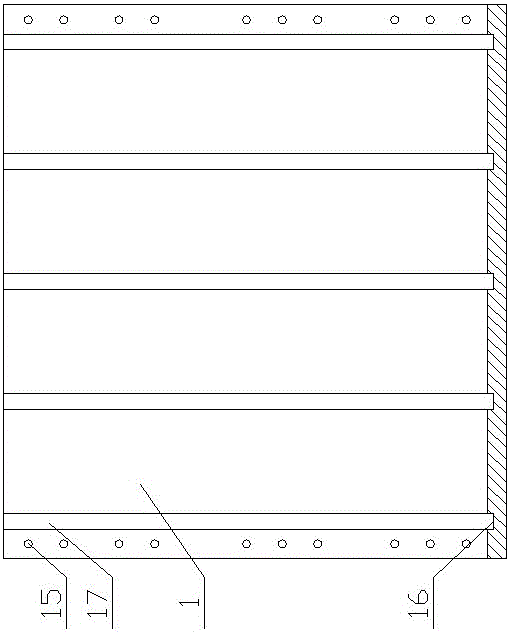

[0044] to combine figure 1 , figure 2 , Figure 8 and Figure 9 As shown, the present invention includes a wallboard frame member 1 with a “U” structure in cross section, and a plurality of ribs 2 are fixed in sequence along the length direction of the wallboard frame member 1 in the groove of the wallboard frame member 1. In the groove of the wall panel frame member 1 , a hidden beam 3 is fixed on the rib 2 , and the filler 14 is filled in the groove of the wall panel frame member 1 between the rib 2 and the hidden beam 3 .

[0045]The bottom and side walls of the groove of the wallboard frame member 1 are respectively provided with corresponding and connected positioning grooves A16 and positioning grooves B17, and the top of the positioning groove B17 extends upwards to the top of the wallboard frame member 1 , the two sides of the rib plate 2 are inserted into the groove of the wall panel frame member 1 downward along the positioning groove B17, and the bottom of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com