Stacking shield modular steel support reinforcement structure capable of being installed and disassembled quickly

A technology of reinforcing structure and steel support, applied in shaft equipment, shaft lining, tunnel lining, etc., to achieve the effect of reasonable stress, preventing damage and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

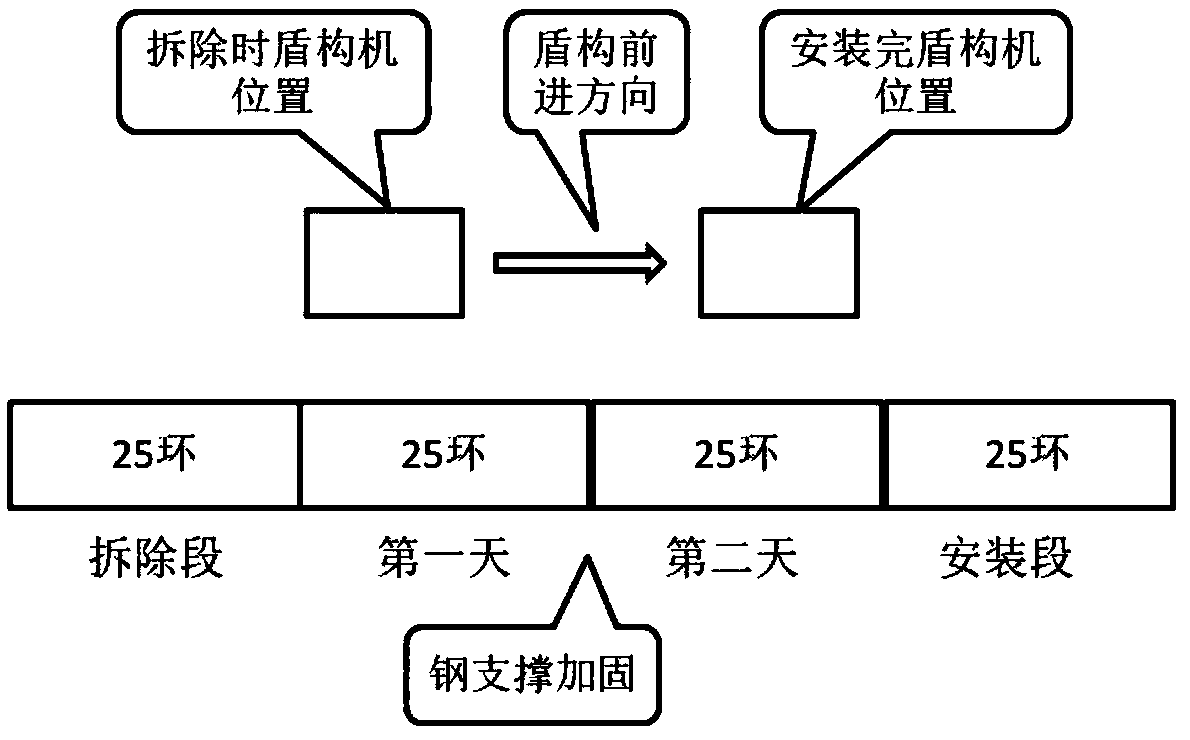

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The embodiment of the present invention discloses a stacked shield modular steel support reinforcement structure that can be quickly installed and disassembled. As shown in the figure, it includes the lower shield tunnel segment (1), and also includes two top modules, two bottom modules;

[0028] The inner side of the shield tunnel segment (1) in the lower layer is provided with a general hoop I-steel support; the hoop I-steel general support is in the shape of a ring and consists of multiple arc-shaped hoop I-steel supports (2) ;

[0029] The structures of the two top modules are symmetrical, and both include hoop I-shaped steel supports (2), vertical steel supports (3), horizontal steel supports one (4), reinforced steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com