Landfill seepage-proof system for prolonging breakdown time of heavy metal irons and breakdown monitoring method

A technology of heavy metal ions and breakdown time, applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc. Realize problems such as industrialization, and achieve the effect of reducing the probability of leakage and polluting the environment, small void ratio, and preventing migration and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

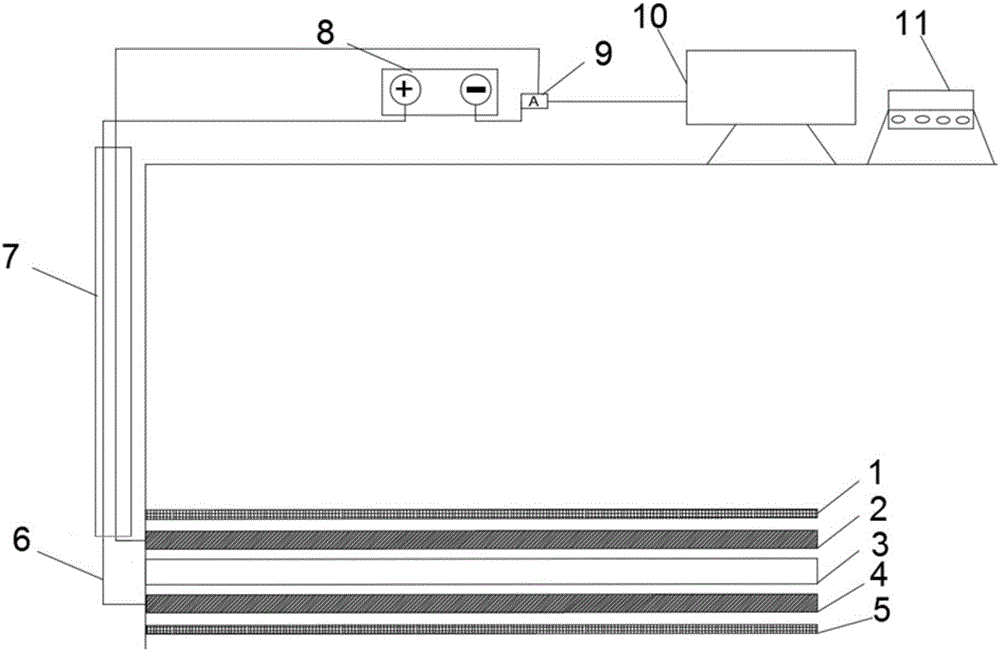

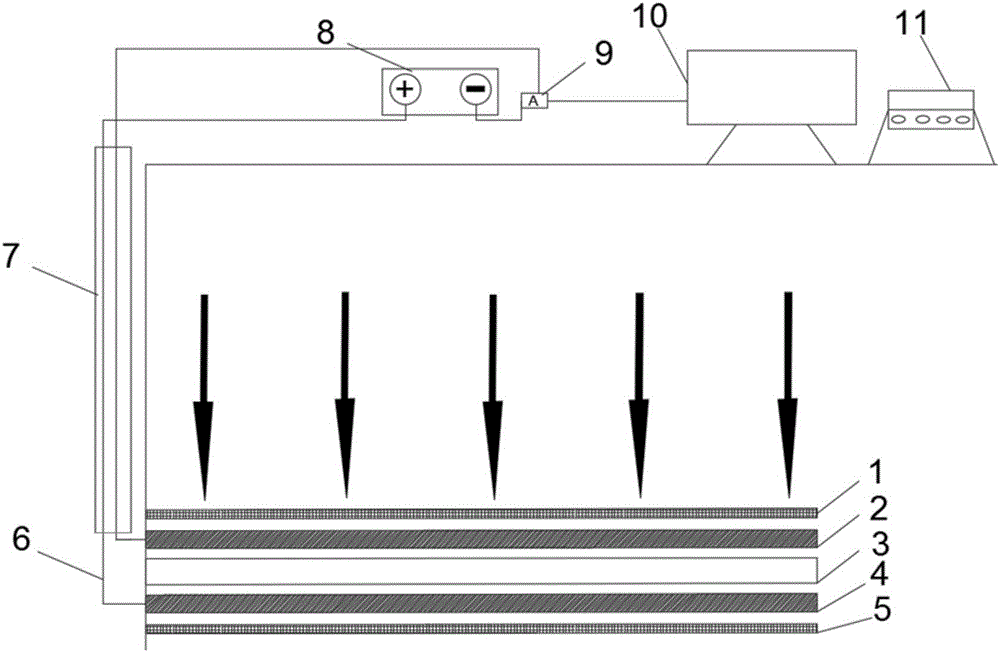

[0028] Such as figure 1 As shown, the present invention provides a landfill anti-seepage system that prolongs the breakdown time of heavy metal ions. The anti-seepage system includes an anti-seepage cushion, a digital DC power supply 8, a current sensor 9, a computer 10 and an alarm device 11; The anti-seepage cushion layer includes the lower outer layer of high-density polyethylene geomembrane (HDPE) 5, the lower conductive geotextile 4, the middle bentonite clay layer 3, the upper conductive geotextile 2, and the upper outer layer of high-density polyethylene geomembrane (HDPE) laminated from bottom to top. Ethylene geomembrane (HDPE) 1; high-density polyethylene geomembrane and conductive geotextile are bonded with a liquid adhesive VAE with a viscosity of 1800; the upper conductive geotextile 2 is connected to the negative pole of digital...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com