Ultra-large-diameter pile foundation assembly type wharf structure and construction method thereof

An ultra-large-diameter, assembled technology, applied in the engineering field, can solve the problems of difficult maintenance, increased construction difficulty, and low assembly level, and achieve the goal of reducing the number of offshore operators, fast node connection speed, and high assembly level. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

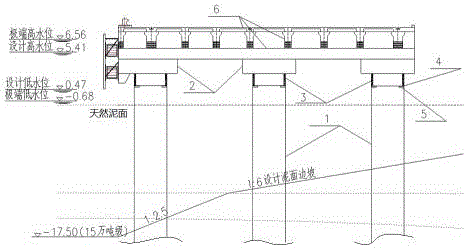

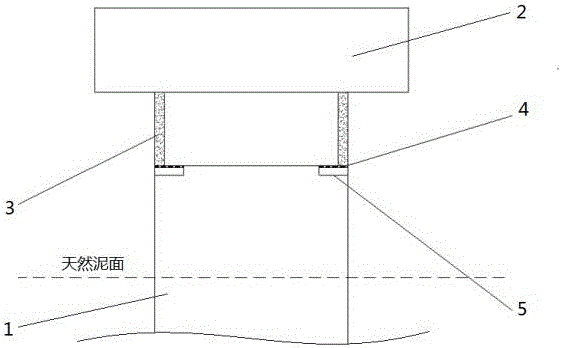

[0025] Such as figure 1 As shown in -2, a super-large-diameter pile foundation assembled wharf structure is composed of super-large-diameter piles 1, T-shaped pile caps 2, rubber pads 3, grout sealing steel plates 4, grouting materials 5, and wharf superstructure 6; The lower end of the super-large-diameter pile 1 is set below the mud surface, the depth is determined according to calculation, and the upper end is welded with a sealing plate 4; the rubber pad 3 is pasted on the sealing plate 4; the T-shaped pile cap 2 is inserted into the The upper end of the super-large diameter pile 1; the grouting material 5 is filled in the gap between the T-shaped pile cap 2, the super-large-diameter pile 1, the rubber pad 3, and the sealing steel plate 4, so that the prefabricated T-shaped pile cap 2 and super-large-diameter pile 1 are integrated; the T-shaped pile cap 2 and the wharf superstructure 6 are all prefabricated in the factory. The top of the T-shaped pile cap 2 is connected t...

Embodiment 2

[0030] A construction method for a super-large-diameter pile foundation assembly type wharf structure, the steps of which are as follows:

[0031] First, prefabricate T-shaped pile caps 2 and prefabricated wharf superstructure 6 in the factory; secondly, weld the sealing steel plate 4 on the upper part of the super large diameter pile 1, paste the rubber pad 3 on the sealing steel plate 4, and set the super large diameter by vibrating hammer Pile 1, after the construction of super-large-diameter pile 1 is completed, the T-shaped pile cap 2 is hoisted and inserted on the upper end of super-large-diameter pile 1 by a crane ship;

[0032] Again, the grouting material 5 is poured into the gap between the T-shaped pile cap 2 and the super-large-diameter pile 1, the rubber pad 3, and the grouting steel plate 4 through the grouting pump, so that the T-shaped pile cap 2 and the super-large-diameter pile 1 are integrated;

[0033] Finally, after the grouting is completed, the wharf sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com