A kind of updraft steam gasification device for biomass and tar mixture

A gasification device and steam technology, applied in the direction of gasification device feeding tool, gasification process, fixed bed gasification, etc., can solve the problem of reducing the temperature of gasification gas, reducing the content of heavy tar, and the deterioration of gasification effect, etc. problem, to achieve the effect of reducing heavy tar content, reducing sensible heat loss, and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

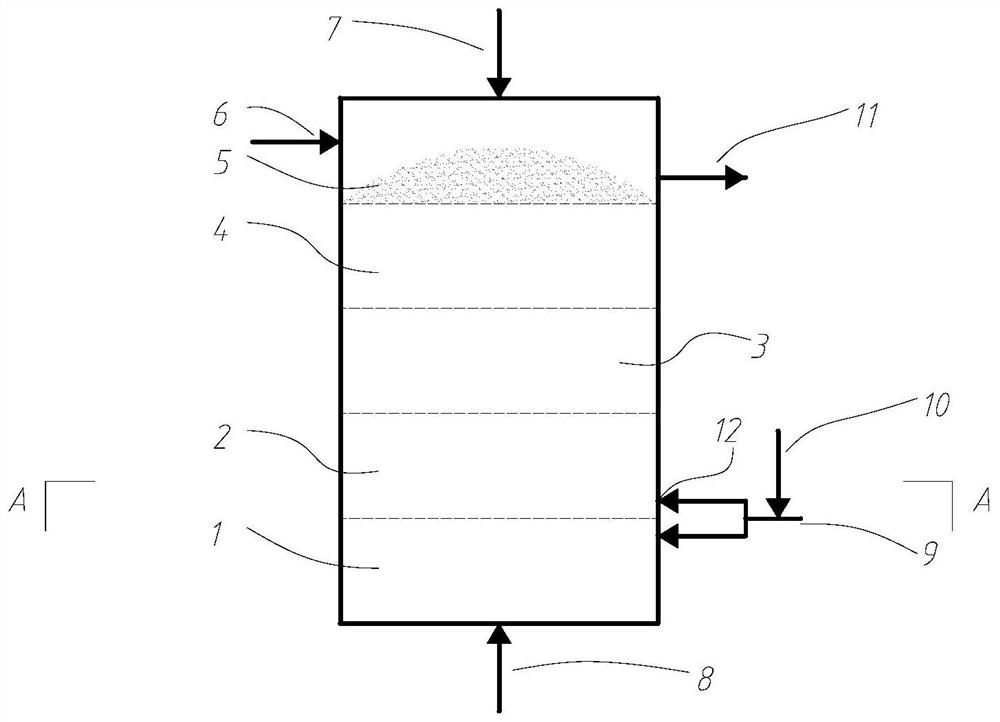

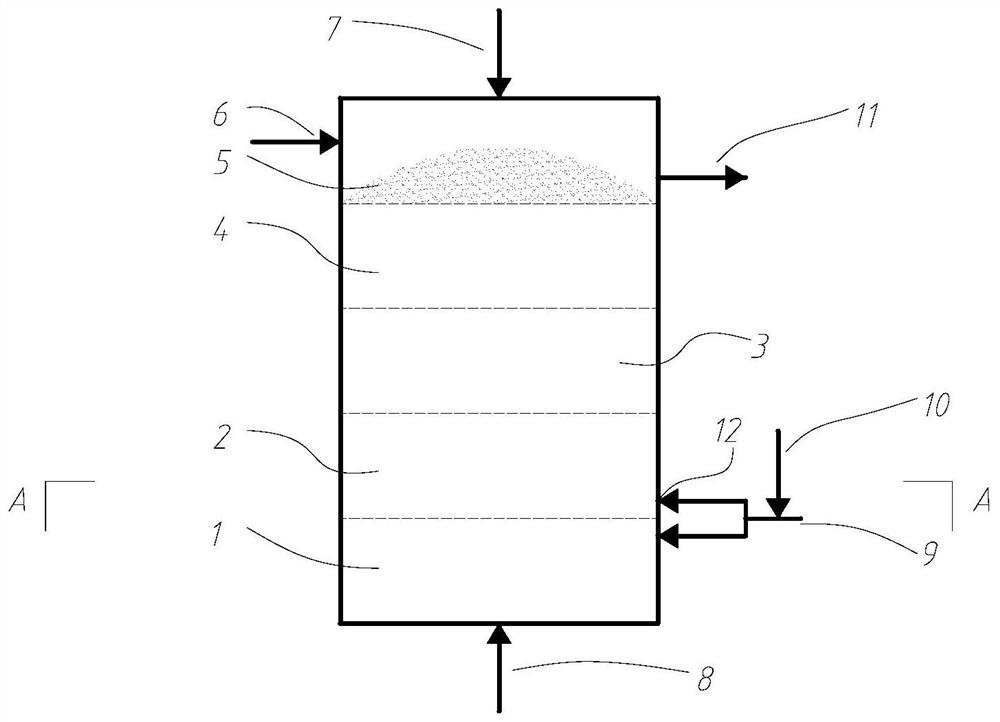

[0026] Such as figure 1A above-mentioned aqueous steam vapor gasification apparatus for biomass and tar mixture, a biomass treatment amount 1.5T / h, the apparatus includes an upper suction gasifier, the main body is a cylindrical refractory masonry 13 and steel furnace shells, lower part of the furnace shell is provided with a rotary furnace row, and the rotary furnace is rowned and distributed and distributed; the upper suction gasification furnace is divided into oxide layers from bottom to top. 1, the reduction layer 2, the pyrolysis layer 3, the drying layer 4 and the mixing zone 5; the upper portion of the upper absolute gasifier is provided with a gas outlet 11 and the feed port 6, and there is 1-3 emulsified priests. The water spray port 7 is provided with an air interface 8 at the bottom of the oxide layer; the gas outlet 11 is connected to an indirect cooler, separating the tar with gas and obtains a lightweight tar water containing a lightweight tar water and a lower la...

Embodiment 2

[0032] Device Reference Example 1, operating load 1T / h, air input is 1000 nm 3 / H, the top-containing heterogeneous aqueous solution is 200 kg / h, the concentration of the heavy tar aqueous solution concentration is 50 wt.%, the bottom saturated water vapor input is about 50 ~ 80 kg / h, which contains lightweight tar water atomization interface. 10 Open, the bottom containing a lightweight tar atomized water input 20 kg / h, where the tar concentration is 15 wt.%. Under this condition, the refocusted oil water and the biomass raw material are mixed in the upper mixing zone of the upper suction gasifier, and the moisture is removed while the moisture is removed while the moisture is removed. Releasing; the raw material removed by moisture is further thermally resolved into volatile division and solid coke, and the volatile division is taken above; the solid coke sequentially enters the lower reduction layer and the oxide layer; simultaneous air from the upper suction gas At th...

Embodiment 3

[0034] Apparatus refers to Example 1, and there is a difference in that the biomass treatment amount is 2T / h, and four emulsified tar water spray inlet 7 are mounted on the top of the apparatus. The oxide layer 1 and the reduction layer 2 are in the circumferential direction of 4 A common nozzle interface 12.

[0035] Operation load 2T / h, the top having a heavy water solution in the top is 300 to 500 kg / h, and the air passage through the air interface 8 is 2000 nm. 3 / h, the bottom is 650 kg / h by the saturated water vapor input of the pressurized water vapor interface 9, the saturated water vapor parameters are 0.25 ~ 0.4 MPa, 127 to 143 ° C, and the bottom passes through a lightweight tar atomized water interface 10. Lightweight tar atomized water input 100 kg / h, wherein the tar content is 50 to 100 g / L. Under this operating conditions, the heavy tar-containing water solution and the biomass raw material are 1.0 to 1.5 h in the upper mixing zone of the upper suction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com