Composite pavement bonding material and preparation method thereof and waterproof crack resistant layer

A composite pavement and bonding material technology, applied in the field of pavement construction materials, can solve the problems of reducing crack resistance and affecting the structural integrity of polyester fiberglass cloth and pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

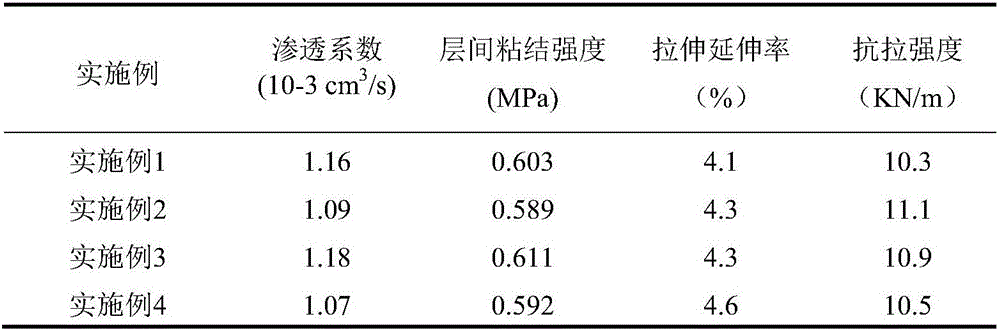

Examples

preparation example Construction

[0046] The preparation method of the adhesive material of the present invention is prepared by mixing high polymer adhesive and self-repairing microcapsules.

[0047] In the above preparation method, a preparation method of PUA adhesive can be provided. The method comprises the following steps: (1) polycondensing polyether polyol and polyisocyanate to obtain a polyurethane prepolymer; (2) reacting the polyurethane prepolymer and polyacrylate while adding a chain extender.

[0048] In the preparation method of the PUA adhesive, the polyether polyol is an oligomer whose main chain contains an ether bond (—R—O—R—), and whose end group or side group contains more than 2 hydroxyl groups (—OH). The polyether polyol can be polyoxypropylene polyol, polymer polyol, polytetrahydrofuran and its copolyether polyol, polyethylene oxide polyol.

[0049] The above-mentioned polyisocyanates refer to isocyanates containing two NCO groups. Examples thereof include difunctional isocyanate compo...

Embodiment 1

[0064] Step 1, preparing polyurethane-acrylate adhesive. Take a certain amount of polyether polyol and put it in the reactor of the device stirrer, heater and temperature sensor, stir rapidly and raise the temperature to about 90°C, connect the vacuum device, continue to heat up to 110°C and keep it warm, vacuum dehydration for 2 hours, Then cool it down to about 50°C, stop vacuuming, add diphenylmethane diisocyanate, first stir rapidly to let it heat up naturally, after the temperature is stable, slowly raise the temperature and control the reaction temperature at 75°C, react for about 4 hours, wait for the reaction After completion, a vacuum device is connected to carry out vacuum degassing, and the obtained polyurethane prepolymer is sealed and stored for later use. Then, mix the polyurethane prepolymer and polyacrylate at a mass ratio of 1:0.4, add a chain extender, and stir quickly to make it fully react to obtain a polyurethane-acrylate adhesive.

[0065] Step 2, prepar...

Embodiment 2

[0069] Step 1, preparing polyurethane-acrylate adhesive. Take a certain amount of polyether polyol and place it in the reactor with stirrer, heater and temperature sensor, stir rapidly and heat up to about 90°C, connect the vacuum device, continue to heat up to 110°C and keep it warm, vacuum dehydration for 2 hours, Then cool it down to about 50°C, stop vacuuming, add diphenylmethane diisocyanate, first stir quickly to let it heat up naturally, after the temperature is stable, slowly raise the temperature and control the reaction temperature at 85°C, react for about 2 hours, and wait for the reaction After completion, a vacuum device is connected to carry out vacuum degassing, and the obtained polyurethane prepolymer is sealed and stored for later use. Then, mix the polyurethane prepolymer and polyacrylate at a mass ratio of 1:0.6, add a chain extender, and stir quickly to make it fully react to obtain a polyurethane-acrylate adhesive.

[0070] Step 2, preparing self-healing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com