Steel super-stain resistant paint and preparation method thereof

An ultra-fouling and coating technology, applied in anti-fouling/underwater coatings, coatings, paints containing biocides, etc., which can solve the problems of large manpower and material resources, poor anti-fouling performance of coatings, and clearing out small advertisements. , to achieve the effect of saving manpower and material resources, super anti-sticking, easy to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

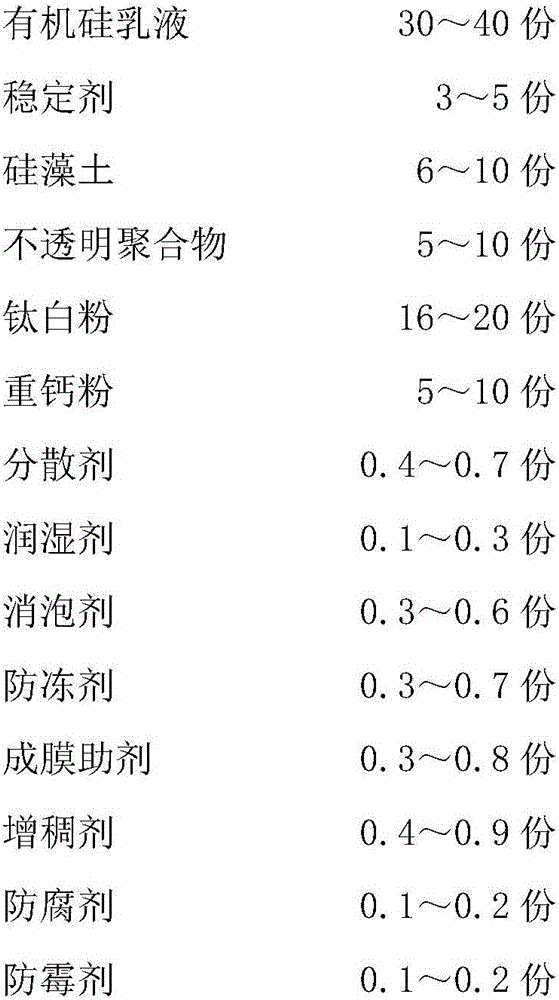

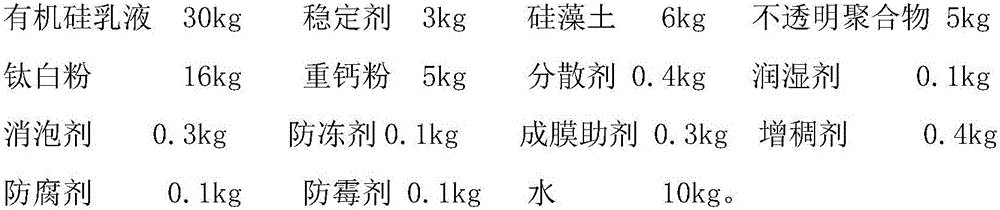

[0024] A tempered super stain-resistant paint, comprising the following components:

[0025]

[0026] The silicone emulsion is the domestic Xinguang silicone emulsion whose model is XG-2618; the diatomaceous earth is the diatomaceous earth whose model is celite 495 produced by the American World Minerals Company; The wetting agent is that the model that U.S. Air Products Company produces is the ethoxylated wetting agent of Carbowet 13-40; Ether and emulsifier mixture class defoamer; Antifreeze is propylene glycol, film-forming aid is alcohol ester twelve; The model of RHEOLATE425 polyacrylate thickener produced by Elementis Special Chemicals Co., Ltd. is 0.16kg of hydroxyethyl cellulose thickener and 0.24kg of polyacrylate thickener; The model produced is polyphase PW40 IPBC antifungal agent.

[0027] The preparation method of this tempered super antifouling paint comprises the steps of following order:

[0028] 1. Premixing: Add 7kg of water in the dispersion tank, then...

Embodiment 2

[0033] A tempered super stain-resistant paint, comprising the following components:

[0034]

[0035] The silicone emulsion is the domestic Xinguang silicone emulsion whose model is XG-2618; the diatomaceous earth is the diatomaceous earth whose model is celite 495 produced by the American World Minerals Company; The wetting agent is that the model that U.S. Air Products Company produces is the ethoxylated wetting agent of Carbowet 13-40; Ether and emulsifier mixture class defoamer; Antifreeze is propylene glycol, film-forming aid is alcohol ester twelve; The model of RHEOLATE425 polyacrylate thickener produced by Elementis Special Chemicals Co., Ltd. is 0.54kg of hydroxyethyl cellulose thickener and 0.36kg of polyacrylate thickener; The model produced is polyphase PW40 IPBC antifungal agent.

[0036] The preparation method of this tempered super antifouling paint comprises the steps of following order:

[0037] 1. Premixing: Add 24kg of water in the dispersion tank, the...

Embodiment 3

[0042] A tempered super stain-resistant paint, comprising the following components:

[0043]

[0044] The silicone emulsion is the domestic Xinguang silicone emulsion whose model is XG-2618; the diatomaceous earth is the diatomaceous earth whose model is celite 495 produced by the American World Minerals Company; The wetting agent is that the model that U.S. Air Products Company produces is the ethoxylated wetting agent of Carbowet 13-40; Ether and emulsifier mixture class defoamer; Antifreeze is propylene glycol, film-forming aid is alcohol ester twelve; The model of RHEOLATE425 polyacrylate thickener produced by Elementis Special Chemicals Co., Ltd. is 0.3kg of hydroxyethyl cellulose thickener and 0.3kg of polyacrylate thickener; The model produced is polyphase PW40 IPBC antifungal agent.

[0045] The preparation method of this tempered super antifouling paint comprises the steps of following order:

[0046]1. Premixing: Add 15kg of water in the dispersion tank, then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com