A radiation-resistant polymer material and its preparation method and application

A polymer material and radiation-resistant technology, which is applied in the field of radiation-resistant polymer materials and their preparation, can solve the problems of color change, mechanical performance decline, mechanical performance decline is not obvious, thermal performance changes little, etc., to achieve thermal performance Little change, no obvious decline in mechanical properties, and the effect of inhibiting degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

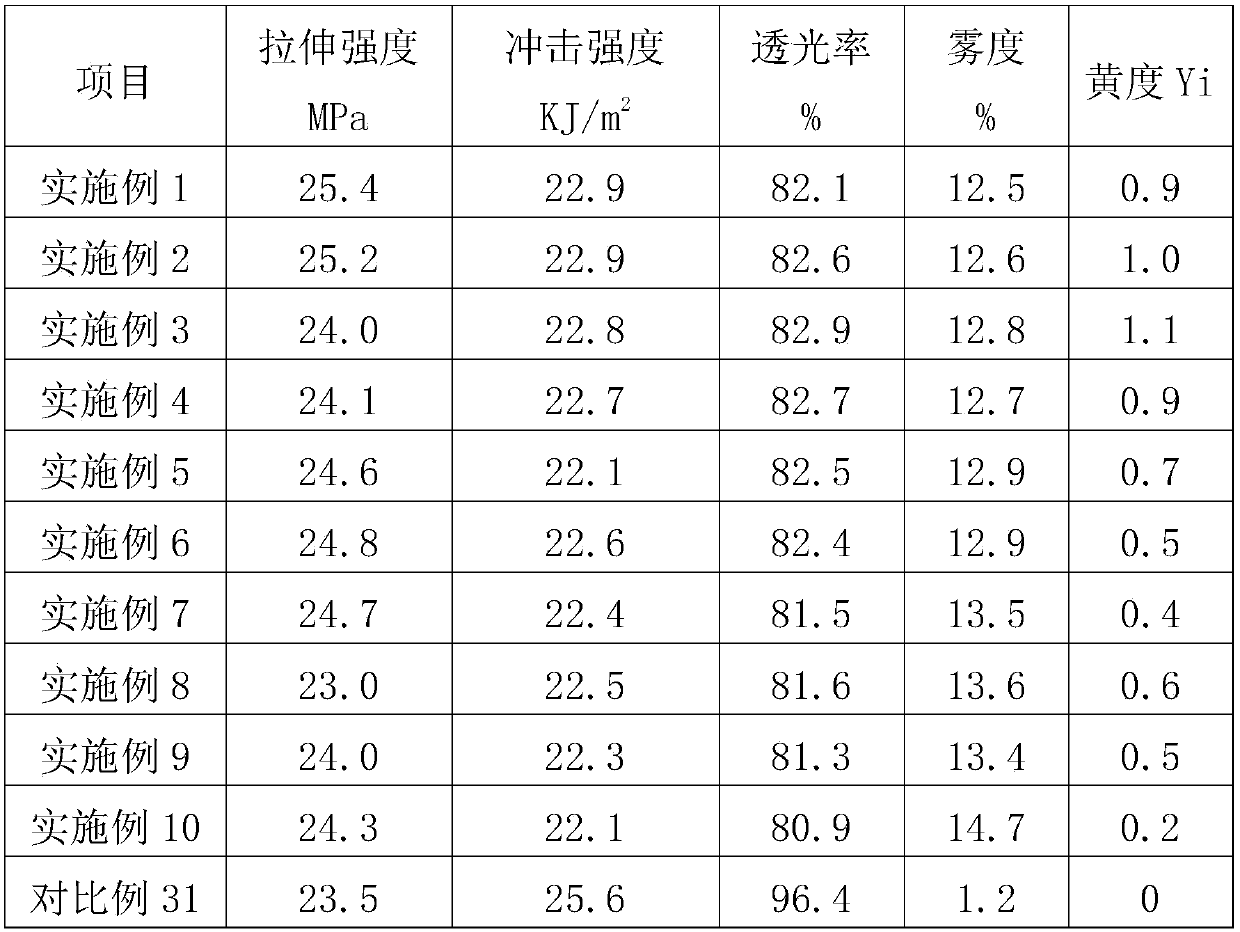

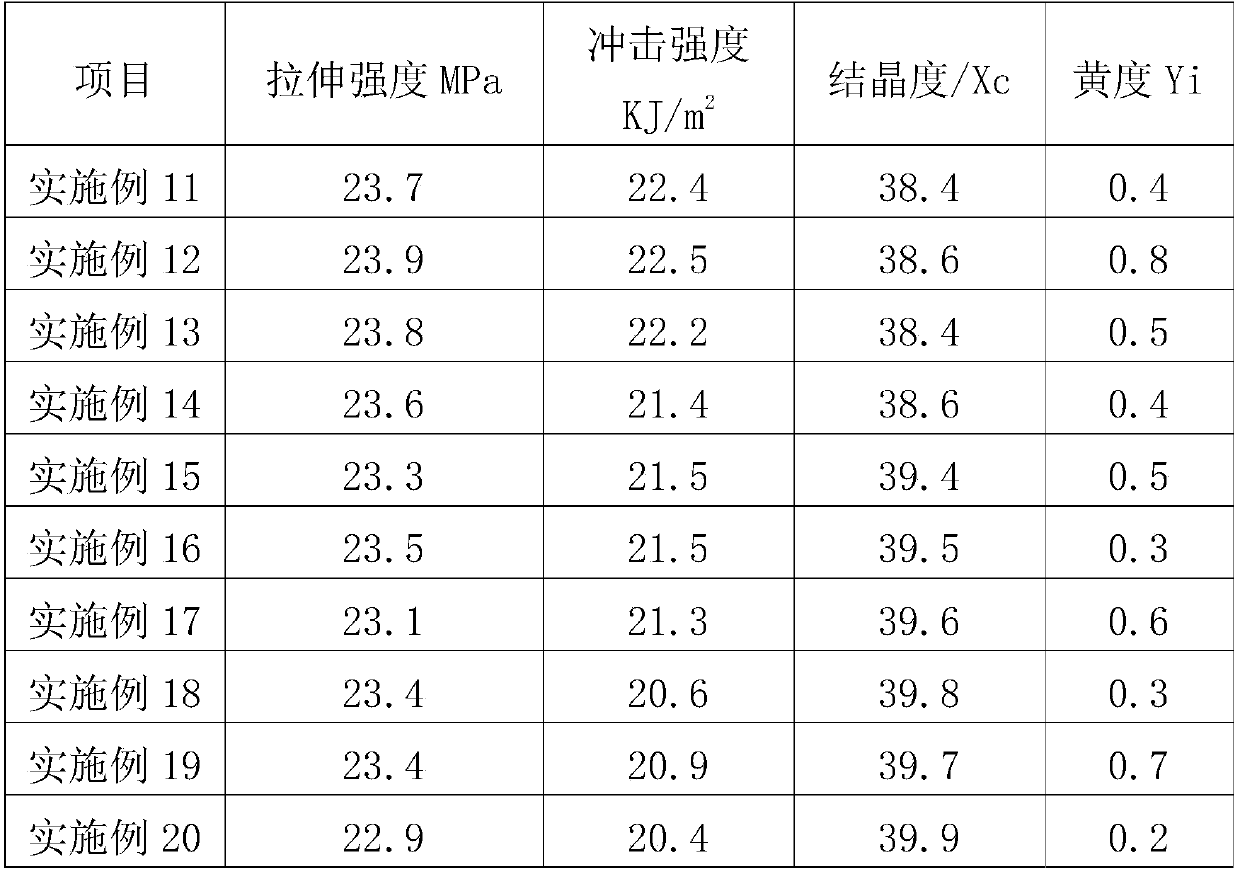

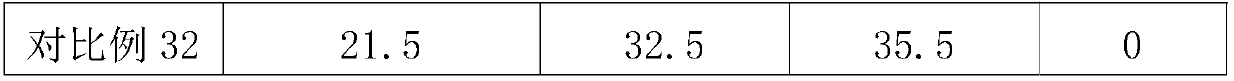

Examples

Embodiment 1

[0045] Add 100 parts by weight of polyvinyl chloride (the brand is SG6, purchased from Tianjin Organic Chemical No. 2 Factory) and 2 parts of calcium-zinc composite stabilizer (type 106-8 of Shanghai Yongyan Chemical Technology Co., Ltd.) , start stirring, the paddle speed is 950rpm, the temperature rises to 90 ° C, maintain the speed and temperature, add 10 parts of epoxy soybean oil, stir and mix for 15 minutes, transfer the mixture to a double-roller mixer with 5 parts of inorganic nano Particle zinc oxide, 5 parts of main antioxidant 1076 and 5 parts of auxiliary antioxidant 168 (BASF China Co., Ltd.) were mixed, the mixing temperature was controlled at 165 ° C, and the mixing time was 10 minutes, and then the total obtained by mixing The mixture was pressed into tablets by a flat vulcanizer, and the prepared samples were placed at room temperature for more than 24 hours, and then cut into test strips with a universal sample making machine, and the performance tests were pe...

Embodiment 2

[0047] Add 100 parts by weight of polyvinyl chloride (the brand is SG6, purchased from Tianjin Organic Chemical No. 2 Factory) and 2 parts of calcium-zinc composite stabilizer (type 106-8 of Shanghai Yongyan Chemical Technology Co., Ltd.) , start stirring, the paddle speed is 950rpm, the temperature rises to 90 ° C, maintain the speed and temperature, add 10 parts of epoxy soybean oil, stir and mix for 15 minutes, transfer the mixture to a double-roller mixer with 5 parts of inorganic nano Particle zinc oxide, 5 parts of main antioxidant 1076 and 5 parts of hindered amine light stabilizer 770 (BASF China Co., Ltd.) were mixed, the mixing temperature was controlled at 165 ° C, and the mixing time was 10 minutes, and then the mixed obtained The blend was then pressed into tablets by a flat vulcanizer, and the prepared samples were placed at room temperature for more than 24 hours, then cut into the required sample strips for the experiment with a universal sample maker, and the p...

Embodiment 3

[0049] Add 100 parts by weight of polyvinyl chloride (the brand is SG6, purchased from Tianjin Organic Chemical No. 2 Factory) and 2 parts of calcium-zinc composite stabilizer (type 106-8 of Shanghai Yongyan Chemical Technology Co., Ltd.) , start stirring, the paddle speed is 950rpm, the temperature rises to 90 ° C, maintain the speed and temperature, add 10 parts of epoxy soybean oil, stir and mix for 15 minutes, transfer the mixture to a double-roller mixer with 7 parts of inorganic nano Particle zinc oxide, 5 parts of main antioxidant 1076 and 4 parts of ultraviolet absorber UV-531 (BASF China Co., Ltd.) are mixed, the mixing temperature is controlled at 165 ° C, and the mixing time is 10 minutes, and then the mixed obtained The blend was then pressed into tablets by a flat vulcanizer, and the prepared samples were placed at room temperature for more than 24 hours, then cut into the required sample strips for the experiment with a universal sample maker, and the performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com