Printing machine with inkjet printing head, radiation drier and at least one light trap

A technology for printing presses, light capture, applied in the post-processing of printing, printing, printing devices, etc., can solve the problems of inability to perform cleaning methods, insufficient cleaning, long time, etc., achieve fast and satisfactory removal, automatic coupling and the effect of decoupling, compact construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

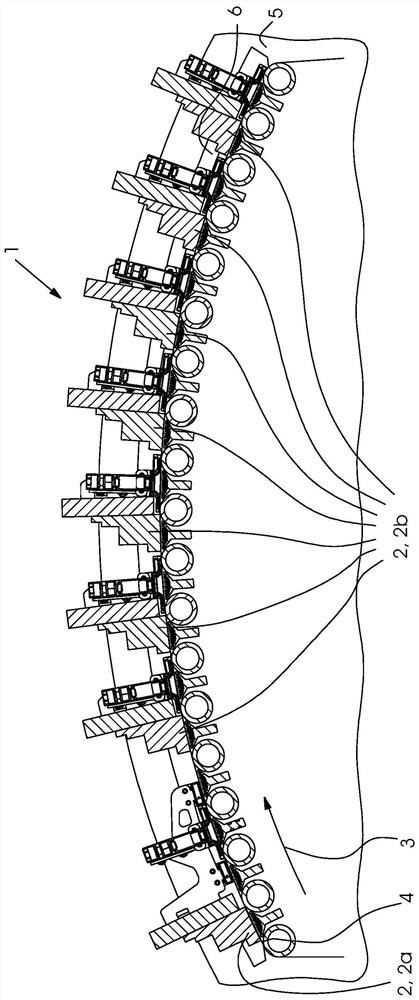

[0029] figure 1 Shown is a side view of a preferred embodiment of a printing machine 1, in particular an ink printing machine 1, with a plurality of ink printing heads 2: one ink printing head 2a for printing white ink (zinc white) ( or a printing mechanism with such an ink print head 2a), and a plurality of ink print heads 2b for printing black ink and / or colored ink (such as the known color K CMY OGV) (or with such an ink print head 2b printing units), the ink printing heads 2b are arranged downstream of the ink printing heads 2a in the conveying direction 3 of the printing material 4 (in particular a web), for example made of paper or plastic film. The ink printing heads 2 are mounted so that they can move up and down (by means of drives not shown) at least in the side wall 5 on the operating side of the machine 1 . The side wall 5 has an opening 6 . The ink printing heads preferably each comprise a nozzle plate with a plurality of individually actuatable nozzles for eje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com