Printing press with ink printhead, radiation dryer and at least one light trap

一种光捕获、印刷机的技术,应用在印刷的后处理、印刷、打印装置等方向,能够解决清洁方法无法执行、清洁不充分、多时间等问题,达到快速且令人满意去除、自动化耦合及脱耦、紧凑建构方式的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

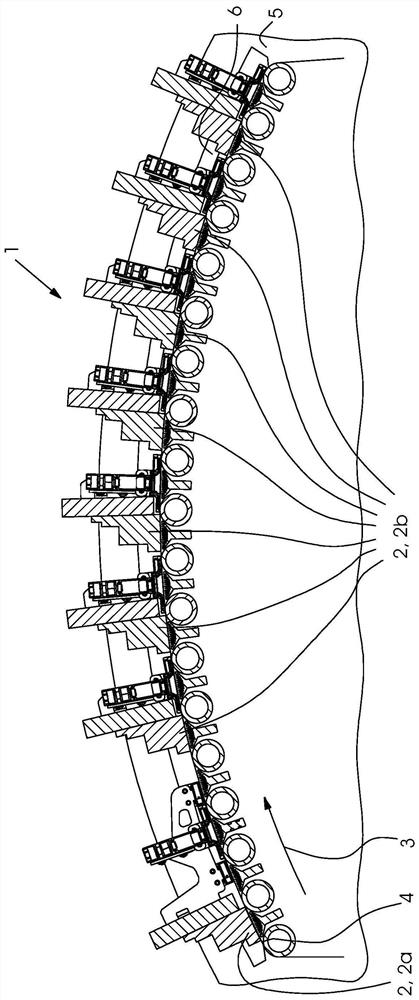

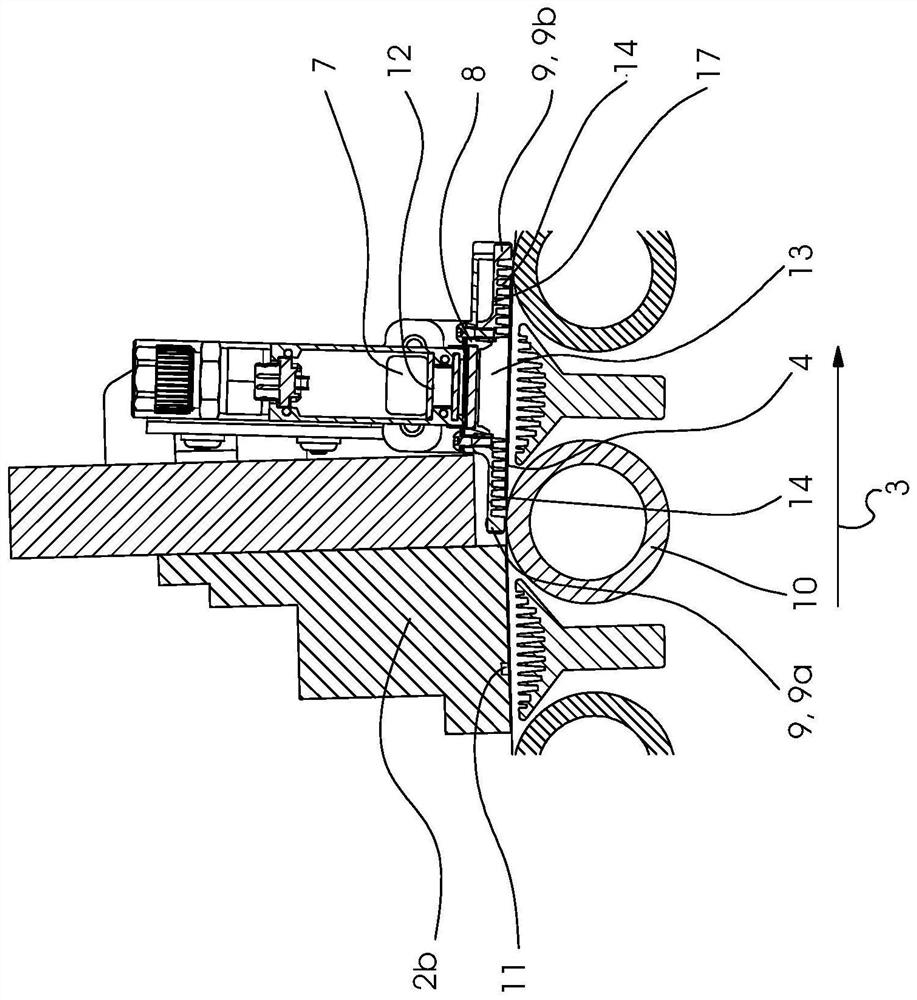

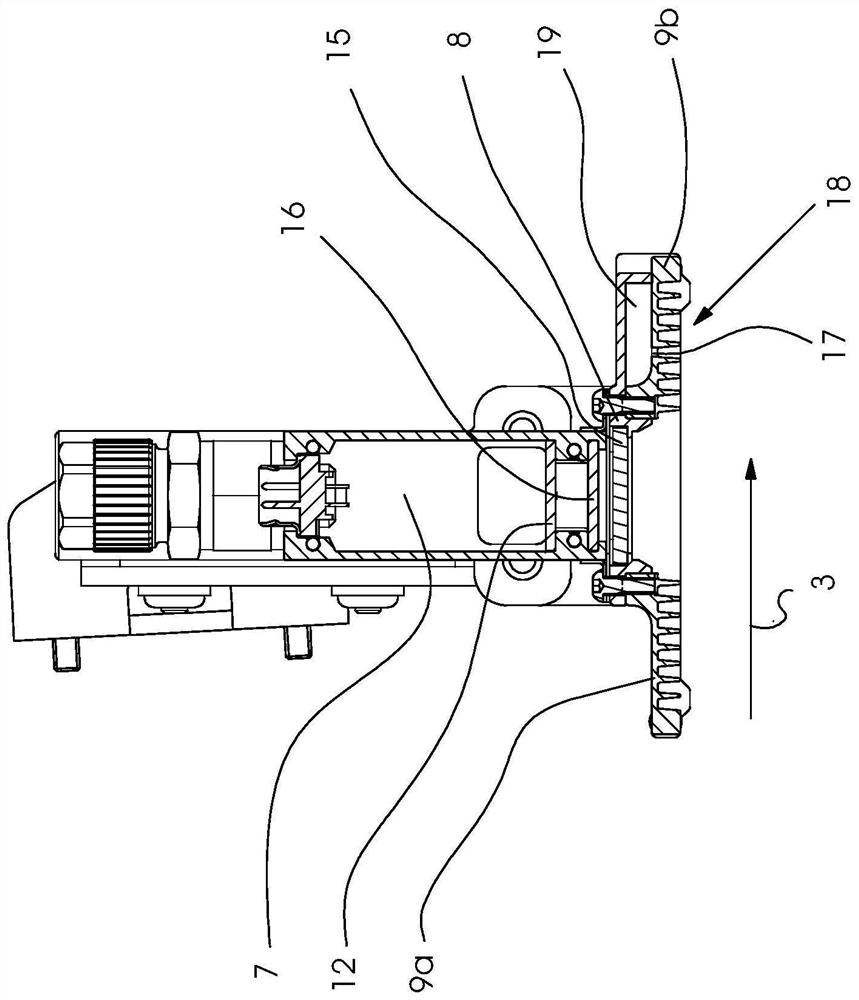

[0028] figure 1 Shown is a side view of a preferred embodiment of a printing machine 1, in particular an ink printing machine 1, with a plurality of ink printing heads 2: one ink printing head 2a for printing white ink (zinc white) ( or a printing mechanism with such an ink print head 2a), and a plurality of ink print heads 2b for printing black ink and / or colored ink (such as the known color K CMY OGV) (or with such an ink print head 2b printing units), the ink printing heads 2b are arranged downstream of the ink printing heads 2a in the conveying direction 3 of the printing material 4 (in particular a web), for example made of paper or plastic film. The ink printing heads 2 are mounted so that they can move up and down (by means of drives not shown) at least in the side wall 5 on the operating side of the machine 1 . The side wall 5 has an opening 6 . The ink printing heads preferably each comprise a nozzle plate with a plurality of individually actuatable nozzles for eje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com