Polysiloxane microsphere damping chlorinated butyl rubber composite material and preparation method thereof

A technology of chlorinated butyl rubber and polysiloxane, which is applied in the field of polysiloxane microsphere damping chlorinated butyl rubber composite materials and its preparation, can solve the problems of inability to increase the damping temperature range and single damping mechanism, etc. Achieve the effect of easy conduction and diffusion, increase cross-link density, and improve damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

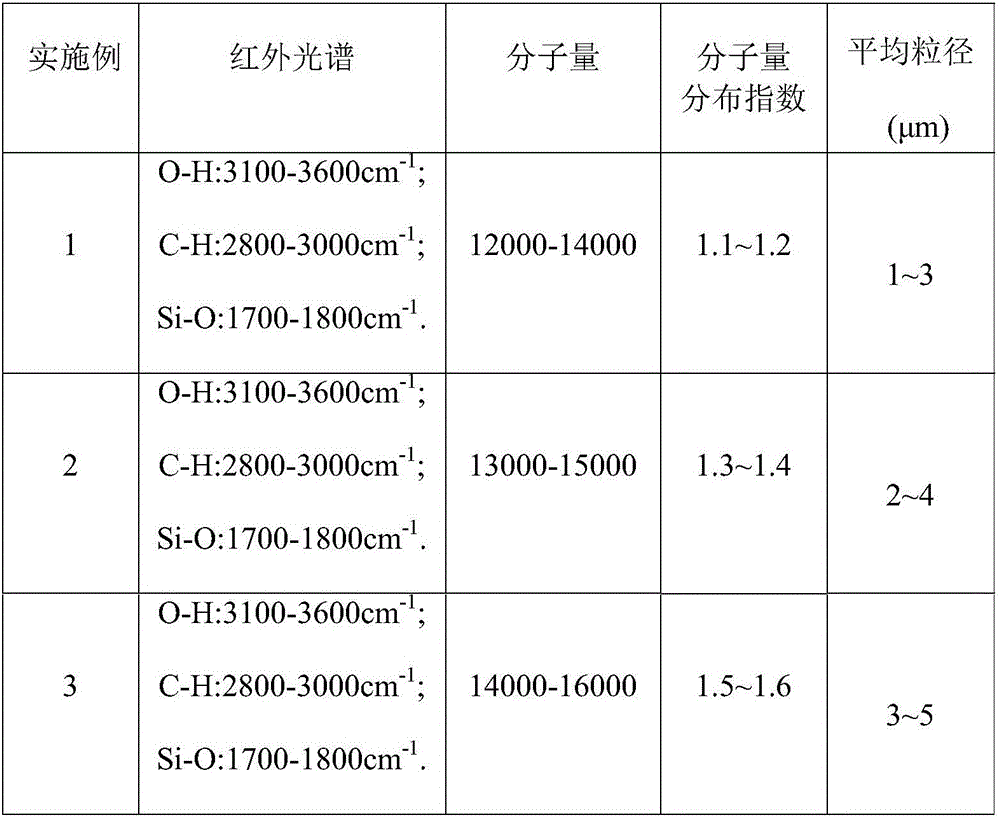

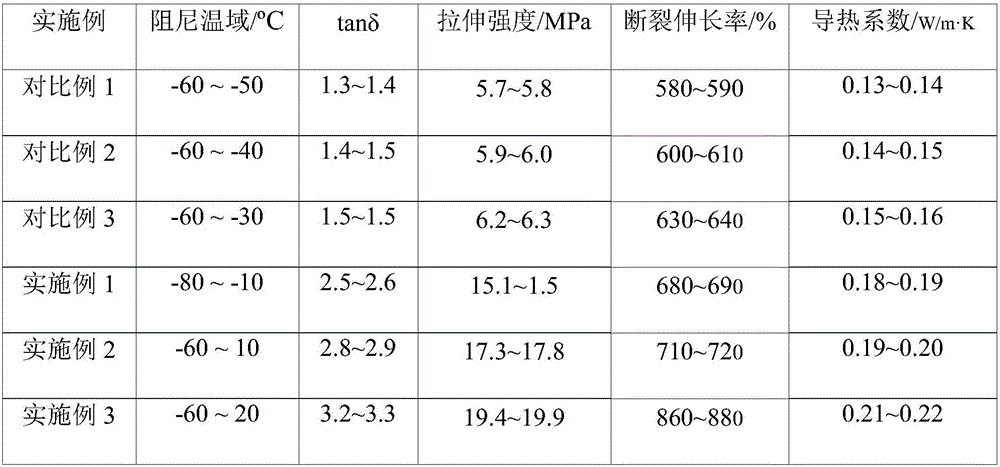

Embodiment 1

[0038] Measure 60g of n-octane and 10g of Span 85, and stir well. Measure 3g of water and add 2ml of ammonia water, stir well. The above mixture was added into a 250mL three-neck flask, and stirring was started at a stirring rate of 300r / min for 1h. Add 10g of methyltrimethoxysilane (MTMS) dropwise, the stirring rate is 500r / min, and the stirring time is 36h, until the reaction is complete, the reactant is suction filtered, and the product obtained by suction filtration is put into an oven for drying to obtain polysiloxane Microspheres. The above-mentioned dried polysiloxane microspheres were sieved by using a 10-mesh sieve for 1 hour, and the obtained polysiloxane microspheres were used as fillers for the modified chlorinated butyl rubber.

[0039] Put 100g of chlorobutyl rubber, 2g of stearic acid, 1g of nano-zinc oxide, 1g of accelerator M, 2g of anti-aging agent A, 1g of light magnesium oxide, 5g of polysiloxane microspheres and 1g of sulfur into the kneading according t...

Embodiment 2

[0043] Measure 70g of n-octane and 15g of Span 85, and stir well. Measure 40g of water and add 3ml of ammonia water, stir evenly. The above mixture was added into a 250mL three-neck flask, and stirring was started at a stirring rate of 400r / min for 2h. Add 20g of methyltrimethoxysilane (MTMS) dropwise, the stirring rate is 650r / min, and the stirring time is 30h, until the reaction is complete, the reactant is filtered by suction, and the product obtained by suction filtration is put into an oven for drying to obtain polysiloxane Microspheres. The above-mentioned dried polysiloxane microspheres were sieved with a 400-mesh screen for 1.5 hours, and the obtained polysiloxane microspheres were used as fillers for the modified chlorobutyl rubber.

[0044]Put 100g of chlorobutyl rubber, 2g of stearic acid, 1g of nano-zinc oxide, 1g of accelerator M, 2g of anti-aging agent A, 1g of light magnesium oxide, 5g of polysiloxane microspheres and 1g of sulfur into the kneading according t...

Embodiment 3

[0048] Measure 80g of n-octane and 20g of Span 85, and stir well. Measure 50g of water and add 4ml of ammonia water, stir evenly. The above mixture was added into a 250mL three-necked flask, and stirring was started at a stirring rate of 500r / min for 1h. Add 30g of methyltrimethoxysilane (MTMS) dropwise, the stirring rate is 800r / min, and the stirring time is 24h, until the reaction is complete, the reactant is suction filtered, and the product obtained by suction filtration is put into an oven for drying to obtain polysiloxane Microspheres. The above-mentioned dried polysiloxane microspheres were sieved by using a 600-mesh screen for 2 hours, and the obtained polysiloxane microspheres were used as fillers for the modified chlorobutyl rubber.

[0049] Put 100g of chlorobutyl rubber, 2g of stearic acid, 1g of nano-zinc oxide, 1g of accelerator M, 2g of anti-aging agent A, 1g of light magnesium oxide, 5g of polysiloxane microspheres and 1g of sulfur into the kneading according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com