Pre-vulcanizing technology of latex medical gloves

A latex and glove technology, which is applied in the field of pre-vulcanization of latex medical gloves, can solve the problems of short service life, poor elasticity, and corrosion resistance, and achieve good anti-aging effects, good elasticity, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

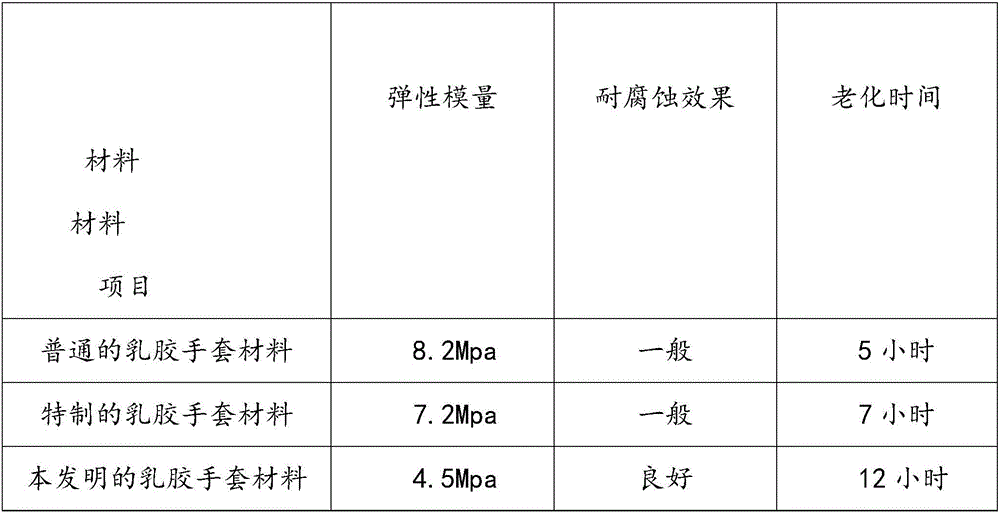

[0030] Experimental object: adopt common latex glove material as control group 1, adopt special latex glove material as control group 2, the latex glove material of the present application as experimental group.

[0031] Experimental requirements: The weight and thickness of the materials in the three experiments are the same.

[0032] Experimental method: The elasticity is measured by the method for measuring the resilience of vulcanized rubber in GB / T 1681-2009, and the elastic modulus data is obtained; the aging time is detected by the aging test box, and the test temperature is adjusted to 85°C and the relative humidity is 85%. The air pressure is 106kPa, the ozone concentration is 45%, and the aging time is obtained; the corrosion resistance effect is carried out by using one of the test standards NACE 0187 / NACE 0296 / GB1690.

[0033] The specific results are shown in the table below:

[0034]

[0035] Combining the above table, comparing the data obtained by the exper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com