A kind of preparation method of heat-resistant, corrosion-resistant high molecular weight polyarylene sulfide sulfone

A polyarylene sulfide sulfone and high molecular weight technology, which is applied in the field of preparation of high molecular weight polyarylene sulfide sulfone, can solve the problems of in-depth synthesis of high-performance PASS resin, few high-functional products, industrialization gap, etc. Operational hazards, low equipment requirements, and the effect of shortened synthesis cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Using hydrous sodium sulfide and 4,4'-dichlorodiphenyl sulfone as raw materials, polyarylene sulfide sulfone is synthesized by heating and maintaining pressure in N-methylpyrrolidone solvent. The synthesis reaction is divided into two steps, with 100Kg 4 , the dosage of 4'-dichlorodiphenyl sulfone as an example, the specific operations are as follows:

[0036] (1) Pre-polymerization:

[0037] Before charging, open the exhaust valve of the dehydration kettle leading to the tail gas absorption tower to release the pressure in the dehydration kettle.

[0038] In the warehouse, transfer 60Kg of sodium sulfide with water to the dehydration reaction workshop by trolley, unpack the sodium sulfide with water and put it into the hopper, and add 1.5Kg of sodium hydroxide and 25kg of 4,4'-dichlorodiphenyl Sulfone, and 8Kg potassium benzoate and 8Kg caprolactone, sodium sulfide, sodium hydroxide, 4,4'-dichlorodiphenyl sulfone, potassium benzoate and caprolactone are discharged int...

Embodiment 2

[0051] According to the operation steps described in Example 1, repeat 3 times, and the average molecular weights of polyarylene sulfide sulfone obtained 3 times are respectively: 31550, 31860, 31570, the molecular weight is high and relatively stable, indicating that the method has good stability and heavy weight. High reproducibility completely solves the instability and low molecular weight of traditional process products; the quality of the final polyarylene sulfide sulfone is: 78.91Kg, 79.23Kg, 79.66Kg, the theoretical output is 83.9 Kg, and the operation is repeated 3 times The lowest yield reaches 94.06%, and the conversion rate is high.

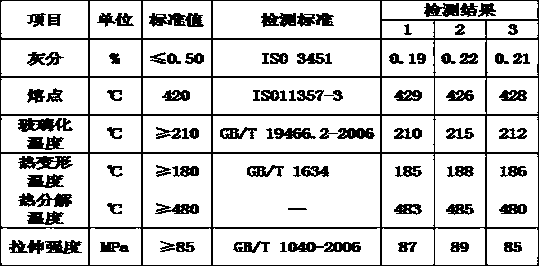

[0052] The physical properties of the polyarylene sulfide sulfone obtained by repeating the operation three times are shown in Table 1:

[0053] Table 1 Physical properties of polyarylene sulfide sulfone

[0054]

[0055] It can be seen from Table 1 that the mechanical properties of polyarylene sulfide sulfone prepared by the meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com