Preparation method of magnetic porous molecularly imprinted polymer

A technology of molecular imprinting and polymers, which is applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of tedious separation and recovery of imprinted adsorbents, time-consuming, limited use efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

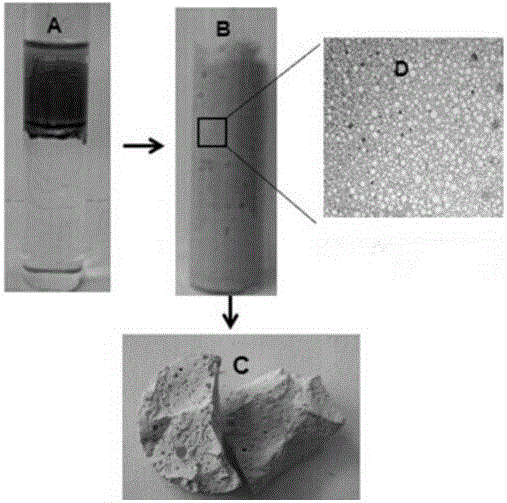

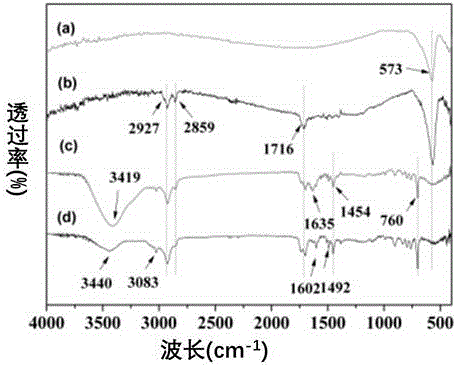

[0036] (1) Preparation of Oleic Acid Modified Ferric Oxide Nanoparticles:

[0037] First, 0.5 g of hydrophilic Fe 3 o 4 The nanoparticles were dispersed in a mixed solution of 1 mL chloroform and 1 mL oleic acid, stirred for 1.5 h, and then dried at 120 °C for 24 h to obtain oleic acid-modified Fe 3 o 4 Nanoparticles (Fe 3 o 4 -OA).

[0038] (2) Preparation of magnetic porous molecularly imprinted polymers (MMIPs):

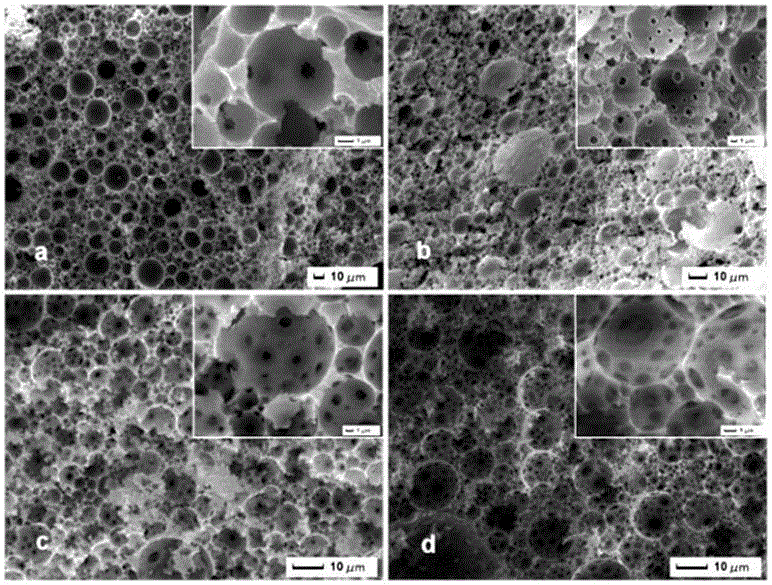

[0039] First, under mechanical stirring, 1.0 mL of styrene (St), 0.2 mL of divinylbenzene (DVB), 0.04 mL of methacrylic acid (MAA), 0.04 g of acrylamide (AM), 0.05 g of cyhalothrin (LC) and 0.06 g of azobisisobutyronitrile (AIBN) were added to a 100 mL round-bottom flask, ultrasonically dispersed for 30 min, and nitrogen was passed through the organic phase and left to stand in the dark, allowing AM, MAA and LC to self-assemble for 12 h. Stir at 400 rpm and add 0.1 g Fe to the organic phase 3 o 4 -OA and 0.5 mL of surfactant Hypermer 2296 to obtain an oil...

Embodiment 2

[0045] (1) Preparation of Oleic Acid Modified Ferric Oxide Nanoparticles:

[0046] First, 1.0 g of hydrophilic Fe 3 o 4 The nanoparticles were dispersed in a mixed solution of 1 mL chloroform and 2 mL oleic acid and stirred for 3 h, then dried at 120 °C for 24 h to obtain oleic acid-modified Fe 3 o 4 Nanoparticles (Fe 3 o 4 -OA).

[0047] (2) Preparation of magnetic porous molecularly imprinted polymers (MMIPs):

[0048] First, under mechanical stirring, 1.5 mL of styrene (St), 0.2 mL of divinylbenzene (DVB), 0.04 mL of methacrylic acid (MAA), 0.04 g of acrylamide (AM), 0.05 g of cyhalothrin (LC) and 0.06 g of azobisisobutyronitrile (AIBN) were added to a 100 mL round-bottom flask, ultrasonically dispersed for 30 min, and nitrogen was passed through the organic phase and left to stand in the dark, allowing AM, MAA and LC to self-assemble for 12 h. Stir at 400 rpm and add 0.2 g Fe to the organic phase 3 o 4 -OA and 0.75 mL of surfactant Hypermer 2296 to obtain an oily ...

Embodiment 3

[0050] (1) Preparation of Oleic Acid Modified Ferric Oxide Nanoparticles:

[0051] First, 1.5 g of hydrophilic Fe 3 o 4 The nanoparticles were dispersed in a mixed solution of 1 mL chloroform and 3 mL oleic acid, stirred for 4.5 h, and then dried at 120 °C for 24 h to obtain oleic acid-modified Fe 3 o 4 Nanoparticles (Fe 3 o 4 -OA).

[0052] (2) Preparation of magnetic porous molecularly imprinted polymers (MMIPs):

[0053] First, under mechanical stirring, mix 2.0 mL of styrene (St), 0.2 mL of divinylbenzene (DVB), 0.04 mL of methacrylic acid (MAA), 0.04 g of acrylamide (AM), 0.05 g of cyhalothrin (LC) and 0.06 g of azobisisobutyronitrile (AIBN) were added to a 100 mL round-bottom flask, ultrasonically dispersed for 30 min, and nitrogen was passed through the organic phase and left to stand in the dark, allowing AM, MAA and LC to self-assemble for 12 h. Stir at 400 rpm and add 0.4 g Fe to the organic phase 3 o 4-OA and 1.0 mL of surfactant Hypermer 2296 to obtain an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com