Camellia soilless culture substrate and preparation method thereof

A technology for soilless cultivation substrate and camellia, which is applied in the directions of soilless cultivation, planting substrate, and botanical equipment and methods, can solve the problems of high cost of raw materials, limited raw materials of camellia cultivation substrate, etc., and achieves a simple preparation method and maintains fertilizer efficiency. Good fertility and water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

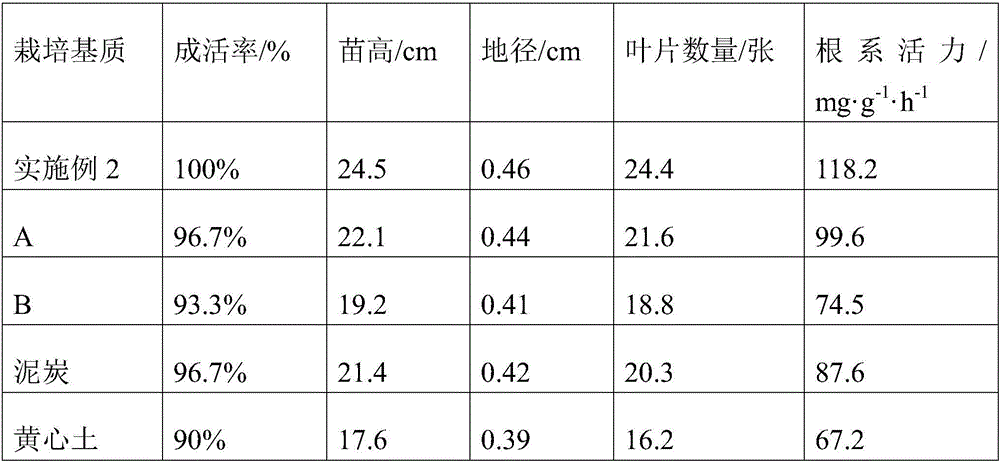

Examples

Embodiment 1

[0030] A camellia soilless cultivation substrate, which is mainly made of the following raw materials in parts by weight: 20 parts of perlite, 20 parts of coconut peat, 10 parts of peat, 5 parts of vermiculite, 5 parts of pine bark, 15 parts of biogas residue, 8 parts of bagasse powder, 5 parts of chicken manure and 15 parts of additive; the additive is diluted wood vinegar

[0031] Preferably, in the above technical scheme, the diluted wood vinegar is 150 times diluted wood vinegar stock solution with water.

[0032] Preferably, in the above technical solution, the perlite is 14-20 mesh. That is, pass through a 14-20 mesh sieve, and select the sieved ones with larger particles to ensure the air permeability of the substrate.

[0033] A preparation method for camellia soilless culture medium, comprising the following steps:

[0034] (1) wet material processed by soaking Hainan coconut peat in water, particle size 1-5mm;

[0035] (2) The pine bark base material is fully comp...

Embodiment 2

[0041] A camellia soilless culture substrate, mainly made of the following raw materials in parts by weight: 15 parts of perlite, 23 parts of coconut peat, 12 parts of peat, 10 parts of vermiculite, 8 parts of pine bark, 10 parts of biogas residue, 5 parts of bagasse powder, 3 parts of chicken manure and 12 parts of additive; the additive is diluted wood vinegar.

[0042] Preferably, in the above technical scheme, the diluted wood vinegar is 100 times diluted wood vinegar stock solution with water.

[0043] Preferably, in the above technical solution, the perlite is 14-20 mesh. That is, pass through a 14-20 mesh sieve, and select the sieved ones with larger particles to ensure the air permeability of the substrate.

[0044] A preparation method for camellia soilless culture medium, comprising the following steps:

[0045] (1) wet material processed by soaking Hainan coconut peat in water, particle size 1-5mm;

[0046] (2) The pine bark base material is fully composted and f...

Embodiment 3

[0052] A camellia soilless cultivation substrate, mainly made of the following raw materials in parts by weight: 12 parts of perlite, 25 parts of coconut peat, 15 parts of peat, 8 parts of vermiculite, 10 parts of pine bark, 8 parts of biogas residue, 8 parts of bagasse powder, 5 parts of chicken manure and 10 parts of additive; said additive is diluted wood vinegar.

[0053] Preferably, in the above technical scheme, the diluted wood vinegar is 50 times diluted wood vinegar stock solution with water.

[0054] Preferably, in the above technical solution, the perlite is 14-20 mesh. That is, pass through a 14-20 mesh sieve, and select the sieved ones with larger particles to ensure the air permeability of the substrate.

[0055] A preparation method for camellia soilless culture medium, comprising the following steps:

[0056] (1) wet material processed by soaking Hainan coconut peat in water, particle size 1-5mm;

[0057] (2) The pine bark base material is fully composted an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com