Two-component stained and sealed hardened floor material

A floor material and two-component technology, applied in the field of building materials, can solve the problems of less improvement in concrete performance, reduced gloss, poor wear resistance, etc., and achieve the effects of easy control of the reaction process, mild reaction conditions, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

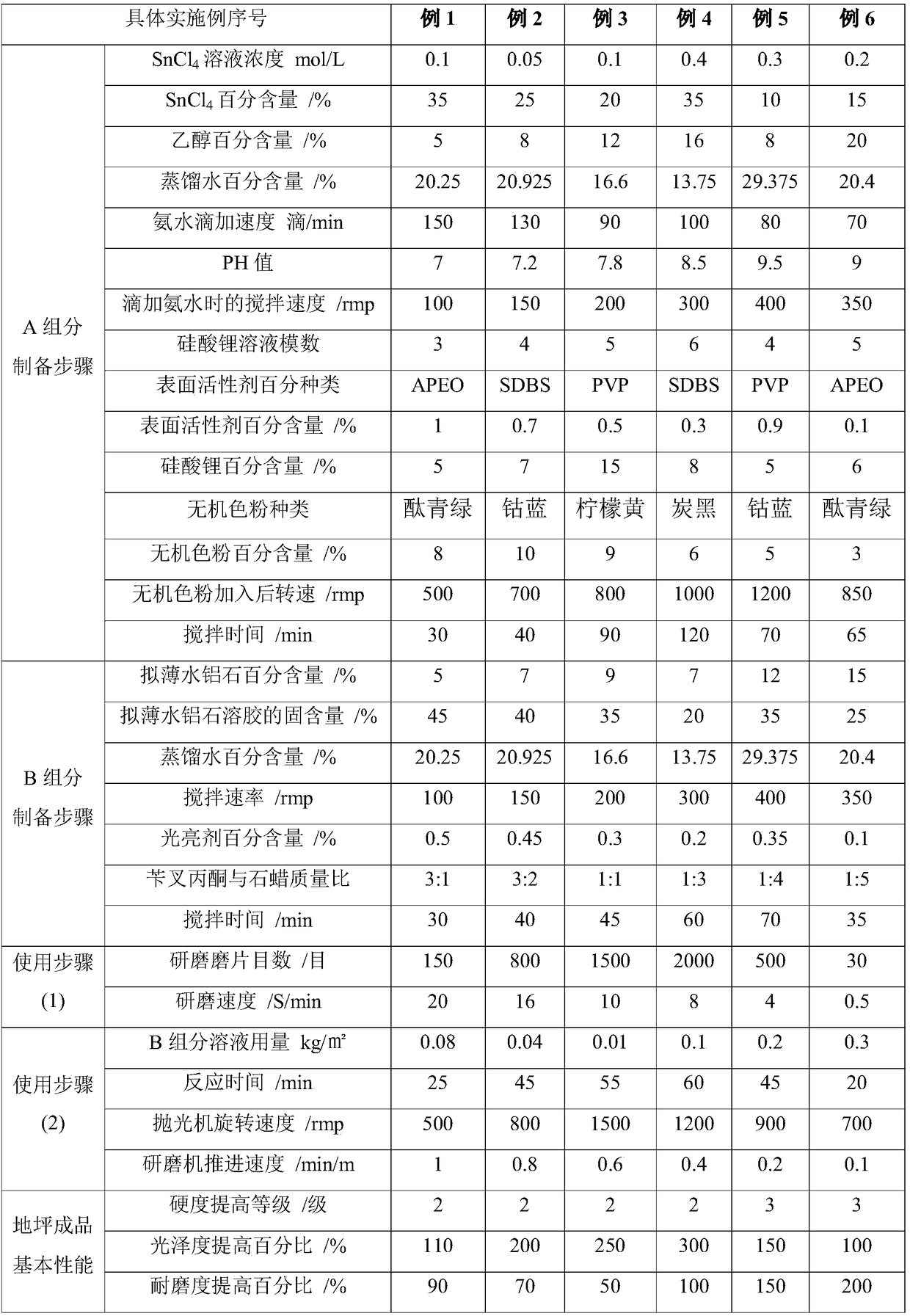

[0033] The present invention will be described in further detail below in conjunction with the examples, but those skilled in the art will understand that the following examples are only used to illustrate the present invention, and should not be considered as limiting the scope of the present invention.

[0034] The two-component dyed and sealed hardened floor material provided by the present invention includes component A and component B, and its components and the percentages of each component in the total mass of the two components are respectively:

[0035] Component A: 10-35% tin tetrachloride, 5-15% lithium silicate, 3-10% inorganic toner, 0.1-1% surfactant, 5-20% ethanol, and distilled water as the balance;

[0036] Component B: 5-15% of pseudo-boehmite, 0.1-0.5% of brightener, and the balance is distilled water; wherein, the molecular formula of boehmite is AlOOH·nH 2 O, n=0.08~0.62.

[0037] The preparation method of the two-component dyed and sealed hardened floor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com