Preparation method of magnesium ceramic with high transparency

A magnesia porcelain, transparency technology, applied in the field of daily ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of magnesia porcelain with high transparency of this embodiment includes the following steps:

[0028] S1. Preparation of the green body: the green body is obtained by ball milling the green material, sieving, and rolling after aging;

[0029] S2, glazing: immerse the body obtained in step S1 in the glaze slurry, and then propose to attach a glaze layer on the surface of the body to obtain a glazing green body;

[0030] S3. Sintering: drying the glaze green body obtained in step S2, transferring it to a kiln in an oxidizing atmosphere for sintering, and cooling to obtain the magnesia porcelain, wherein:

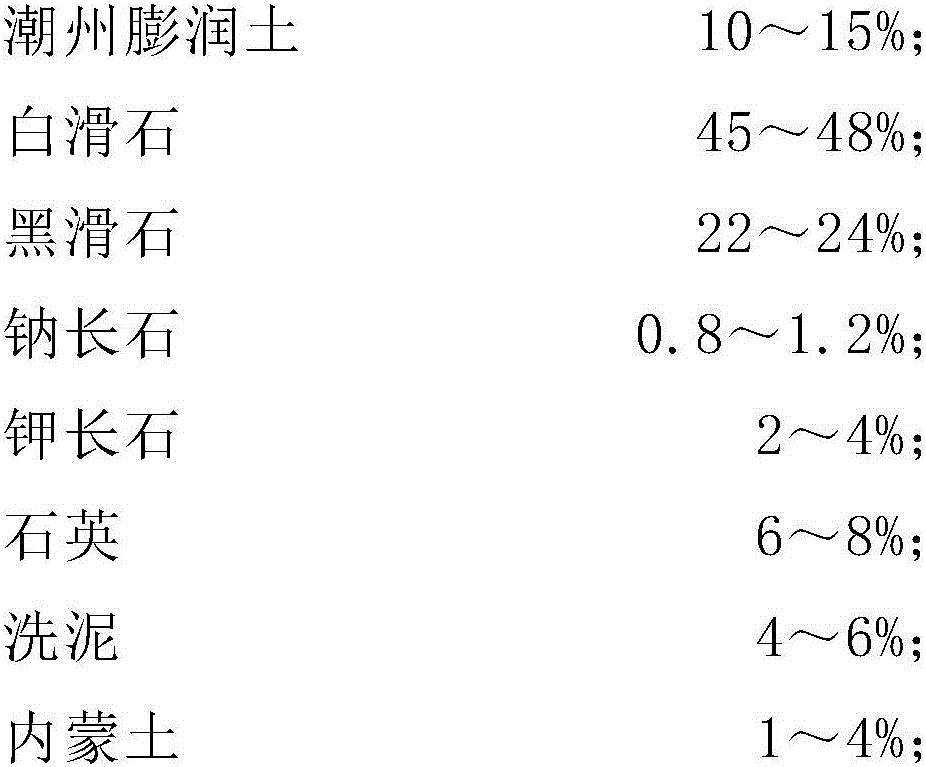

[0031] The above blank is composed of the following raw materials according to mass percentage:

[0032]

[0033] The preparation method of the blank of the strengthened magnesia porcelain in this embodiment is to pulverize white talc, black talc, albite, potash feldspar, quartz, washed mud, and inner Mongolian soil respectively, pass through a 200-400 mes...

Embodiment 2

[0041] The preparation method of magnesia porcelain with high transparency of this embodiment includes the following steps:

[0042] S1. Preparation of the green body: the green body is obtained by ball milling the green material, sieving, and rolling after aging;

[0043] S2, glazing: immerse the body obtained in step S1 in the glaze slurry, and then propose to attach a glaze layer on the surface of the body to obtain a glazing green body;

[0044] S3. Sintering: drying the glaze green body obtained in step S2, transferring it to a kiln in an oxidizing atmosphere for sintering, and cooling to obtain the magnesia porcelain, wherein:

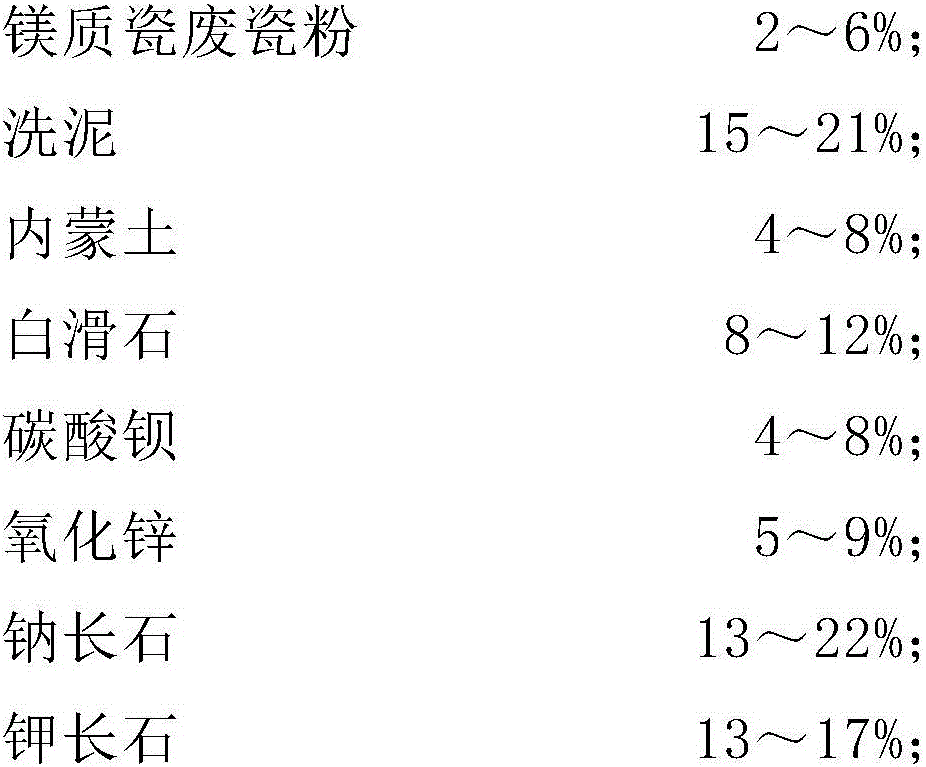

[0045] The above blank is composed of the following raw materials according to mass percentage:

[0046]

[0047] The preparation method of the blank of the strengthened magnesia porcelain in this embodiment is to pulverize white talc, black talc, albite, potash feldspar, quartz, washed mud, and inner Mongolian soil respectively, pass through a 200-400 mes...

Embodiment 3

[0054] The preparation method of magnesia porcelain with high transparency of this embodiment includes the following steps:

[0055] S1. Preparation of the green body: the green body is obtained by ball milling the green material, sieving, and rolling after aging;

[0056] S2, glazing: immerse the body obtained in step S1 in the glaze slurry, and then propose to attach a glaze layer on the surface of the body to obtain a glazing green body;

[0057] S3. Sintering: drying the glaze green body obtained in step S2, transferring it to a kiln in an oxidizing atmosphere for sintering, and cooling to obtain the magnesia porcelain, wherein:

[0058] The above blank is composed of the following raw materials according to mass percentage:

[0059]

[0060] The preparation method of the blank of the strengthened magnesia porcelain in this embodiment is to pulverize white talc, black talc, albite, potash feldspar, quartz, washed mud, and inner Mongolian soil respectively, pass through a 200-400 mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com