Reaction furnace for dealkalizing red mud by non-direct heating and synchronously drying red mud raw material

A technology of indirect heating and reaction furnace, applied in drying, drying machine, heating device and other directions, can solve the problem of insufficient utilization of red mud, reduce production cost and production line investment, safe and stable operation, and save energy Effect and production efficiency Significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

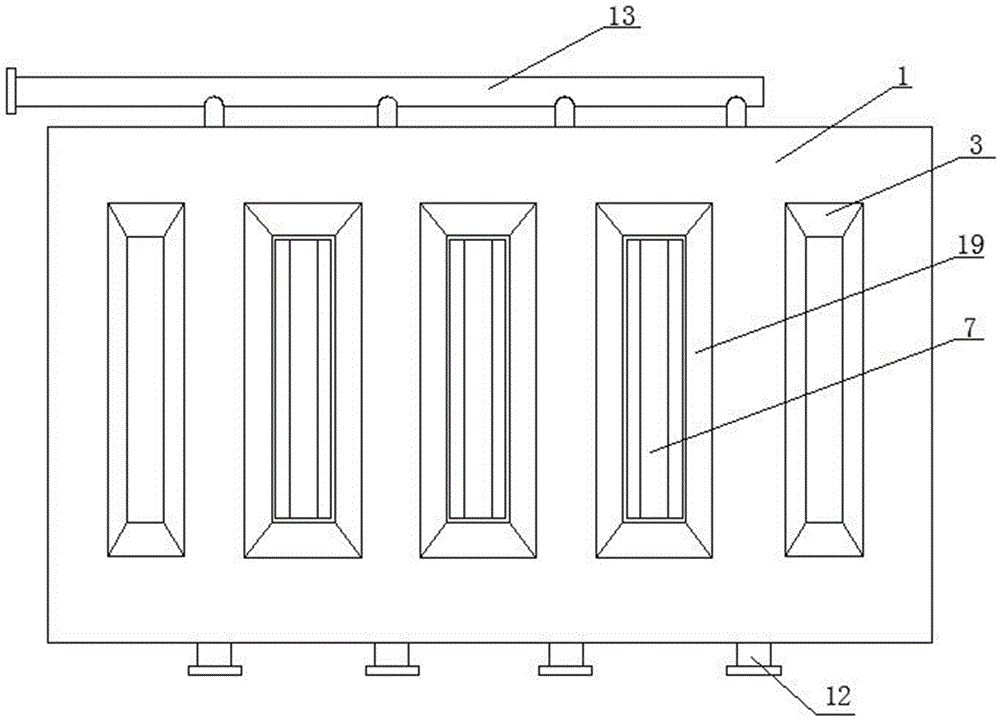

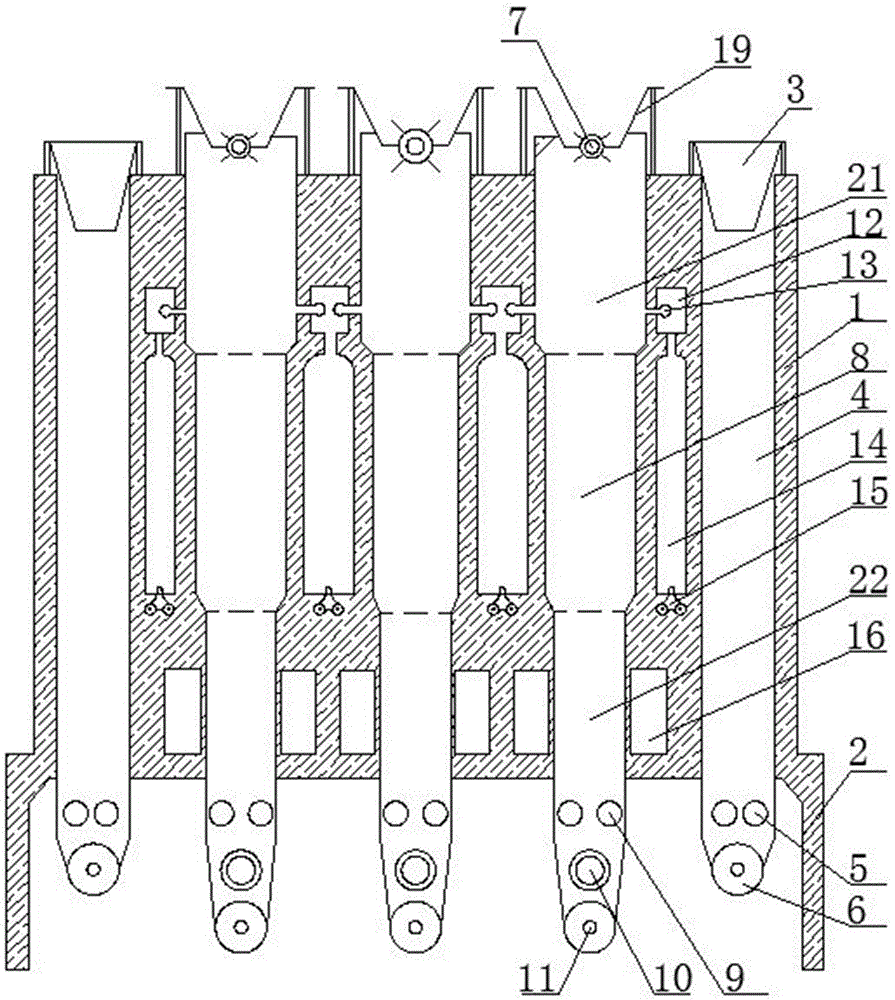

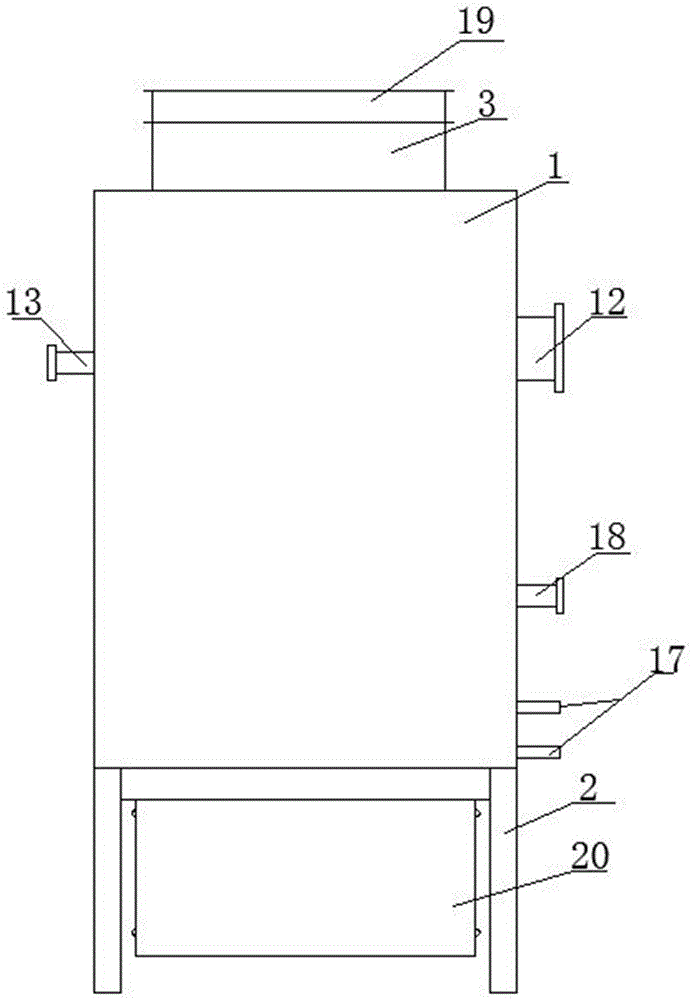

[0033] The present invention proposes a reaction furnace for indirect heating of red mud dealkalization and synchronous drying of red mud raw materials. The waste heat is used to dry the red mud to be treated, and the material moves downward by its own gravity. When designing, the raw material drying system It is organically integrated with the red mud dealkalization reaction system, fully utilizes the waste heat of the reaction, and completes the drying of red mud and other materials without adding a new heat source. The energy saving effect is remarkable, and the production cost and production line investment are effectively reduced, such as Figure 1-7 As shown, the following configuration structure is adopted in particular: including a furnace body 1 and a furnace base 2, a red mud dealkalization reaction system and a raw material drying system using waste heat for raw material drying are arranged in the furnace body 1, and the raw material drying The system is set outside ...

Embodiment 2

[0041] This embodiment is further optimized on the basis of the above embodiments. In order to better realize the present invention, the material can be moved downward by its own gravity, so as to ensure that the material can be dried evenly, so as to pass the quality assurance for subsequent processing. ,Such as Figure 1-7 As shown, the following arrangement structure is adopted in particular: the drying channel 4 is a vertical straight-through structure, and the drying and discharging device is placed in the furnace seat 2 below the furnace body 1. When setting, the drying and discharging The device is arranged at the bottom of the furnace body 1 and placed in the area where the furnace base 2 is set, so that the drying and discharging device can be easily connected with the follow-up system.

Embodiment 3

[0043] This embodiment is further optimized on the basis of any of the above-mentioned embodiments. Further, in order to better realize the present invention, by setting a tower-type reaction chamber with an inverted tower-type structure, a three-stage reaction mode is used to carry out dealkalization reaction of red mud Processing; in the design and application, the reactants rely on their own gravity to move downward by themselves, which has the characteristics of greatly shortening the warm-up time of the reactants, energy saving effect and remarkable production efficiency, and also has the characteristics of fast cooling speed, safe and stable operation, such as Figure 1-7 As shown, the following configuration structure is adopted in particular: the red mud dealkalization reaction system includes a heating system and a tower-type reaction chamber, the heating system is arranged on both sides of the tower-type reaction chamber, and the raw material drying system is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com