Kitchen waste water anaerobic MBR treatment device

A technology for kitchen waste water and treatment equipment, applied in anaerobic digestion treatment, water treatment parameter control, biological water/sewage treatment, etc., can solve problems such as unsatisfactory effect, slow growth rate of anaerobic microorganisms, and inability to reuse. Improve the anaerobic treatment capacity of the kitchen, facilitate replacement and addition, and save treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

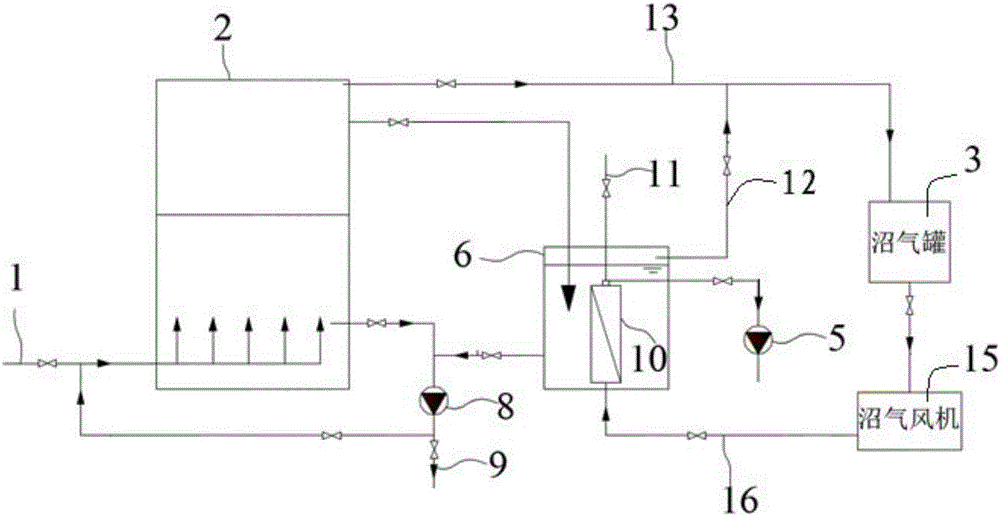

[0012] figure 1 As shown, it relates to a kind of kitchen waste water anaerobic MBR treatment equipment, including kitchen anaerobic digestion tank 2 and anaerobic MBR membrane pool 6, the bottom water inlet of the kitchen anaerobic digestion tank 2 and the kitchen waste water inlet pipe 1 connection, the bottom water outlet of the kitchen anaerobic digester 2 is connected with the sludge return pump 8; the top gas outlet of the kitchen anaerobic digester 2 is connected with the biogas tank 3 through the first biogas collecting pipe 13, The top water outlet of the kitchen anaerobic digestion tank 2 is connected with the anaerobic MBR membrane pool 6; the anaerobic MBR membrane module 10 is arranged in the anaerobic MBR membrane pool 6, and the upper end of the anaerobic MBR membrane module 10 passes through The pipeline is connected to the cleaning port 11 arranged on the top of the anaerobic MBR membrane tank 6, the bottom input end of the anaerobic MBR membrane module 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com