Reverse osmosis membrane element and water purification equipment

A technology of reverse osmosis membrane and element, applied in the field of reverse osmosis membrane element and water purification equipment, can solve the problems of reducing the use efficiency and increasing the use cost, and achieves the effect of simple structure, low production cost and promoting turbulent flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

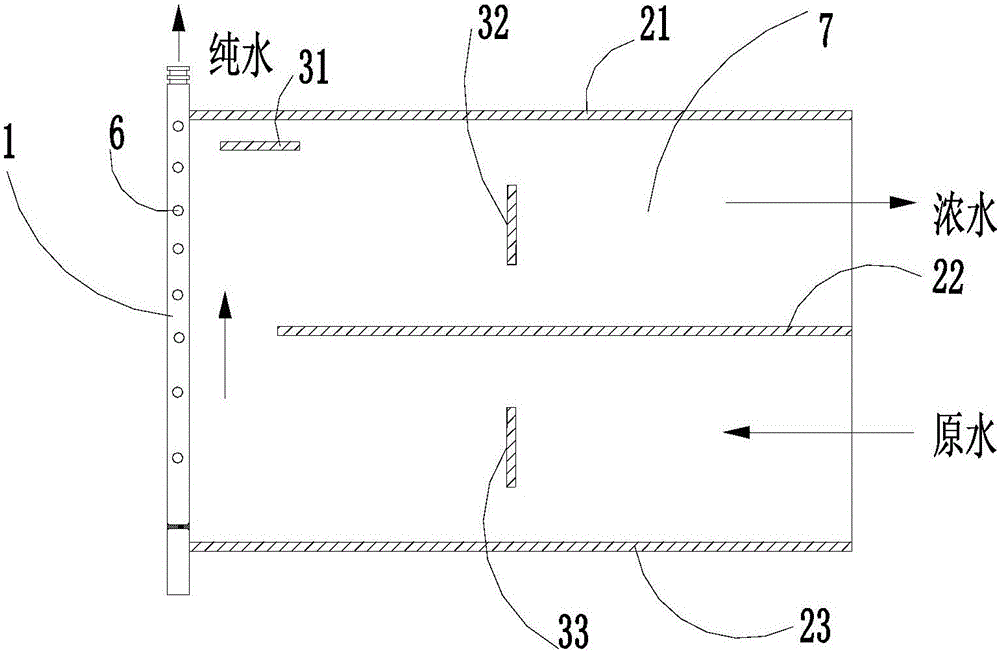

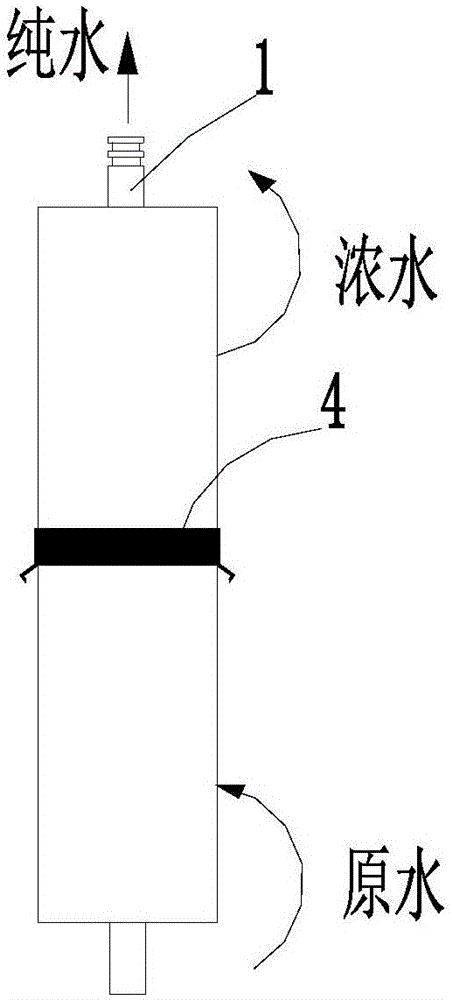

[0033] A reverse osmosis membrane element, comprising a central pipe 1 and a reverse osmosis membrane group wound on the central pipe 1, and a plurality of water inlet holes 6 communicating with the reverse osmosis membrane group are uniformly arranged on the body of the central pipe 1 , the inner end of the reverse osmosis membrane group is fixedly connected with the central pipe 1 .

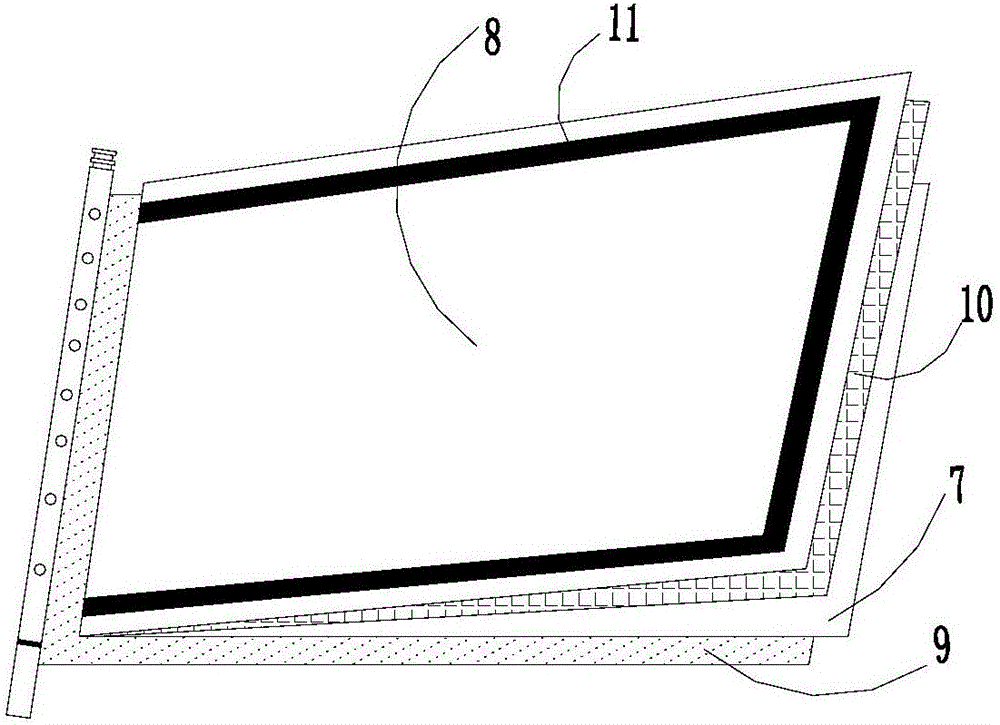

[0034] The reverse osmosis membrane set includes reverse osmosis membranes with 7 opposite folds on the front (i.e. 7 folds on the front to the inside and 8 folds on the back to the outside). The water channel, the raw water or concentrated water in the water inlet channel can only permeate from the front 7 to the reverse 8 of the reverse osmosis membrane, but cannot penetrate from the reverse 8 to the front 7 of the reverse osmosis membrane so as to avoid the obtained pure water from penetrating into the reverse osmosis membrane again. Raw water or concentrated water, that is, the side of the ...

Embodiment 2

[0047] The difference between the second embodiment and the first embodiment is that in the second embodiment, the end caps 51 and 52 are used to replace the second waterproof tapes 21 and 23 in the first embodiment to realize the sealing of both ends of the reverse osmosis membrane element.

[0048] In this embodiment, the reverse osmosis membrane is also provided with a second waterproof adhesive tape 11 around the reverse side, because when the end caps 51 and 52 are used, the raw water or concentrated water will flow out from both sides of the water inlet channel and pass through the second The waterproof adhesive tape 11 can effectively prevent raw water or concentrated water flowing out from the water inlet channel from entering into the produced water channel to pollute the pure water.

[0049] The usage method of the reverse osmosis membrane element of this embodiment is exactly the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com