Method for preparing magnesium oxide or magnesium oxide and fibrous magnesium hydroxide from magnesite

A magnesium hydroxide and magnesium oxide technology, applied in the direction of magnesium hydroxide, magnesium oxide, etc., can solve the problems of calcium carbonate entering impurities, high leaching temperature, and not widely used, and achieve low equipment requirements, less waste, and reduced production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

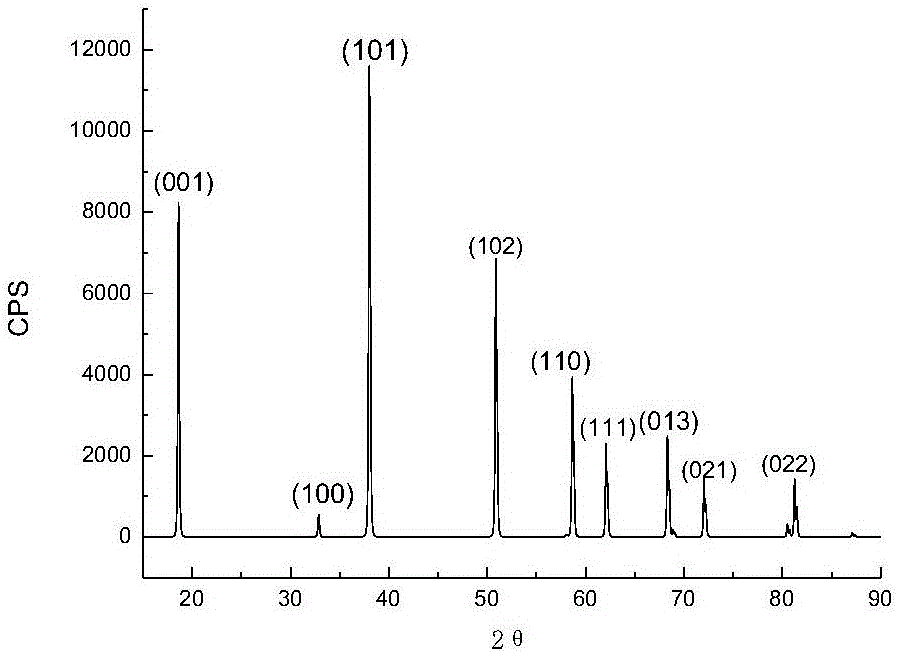

Image

Examples

Embodiment 1

[0057] Example 1 Preparation of high-purity magnesium oxide and fibrous magnesium hydroxide with magnesite

[0058] Experiment 1

[0059] Operate according to the following steps (the process flow diagram of the method is as follows figure 1 shown):

[0060] 1) Use the magnesite in Table 1 as the raw material, calcinate at 1100°C for 0.5h to obtain lightly calcined magnesium powder, and then crush and sieve to obtain calcined magnesium oxide powder with a particle size of -200 mesh.

[0061] 2) Take 2.4kg of solid ammonium sulfate, add water to fully dissolve it, configure the solution volume to 6.1L, then add 970g of light-burned magnesium powder (the solid-liquid ratio of light-burned magnesium powder to ammonium sulfate solution is 159g / L, NH 4 + :MgO molar ratio is 1.7:1), join in the reaction kettle, adjust the water bath temperature 60 ℃, keep stirring during the reaction process, the rotating speed is 300rpm, and adjust the negative pressure to relative vacuum degree...

Embodiment 2

[0073] Example 2 Preparation of high-purity magnesium oxide and fibrous magnesium hydroxide with magnesite

[0074] Experiment 1

[0075] Follow the steps below:

[0076] 1) Use the magnesite in Table 1 as the raw material, calcinate at 700°C for 2 hours to obtain lightly burned magnesium powder, and then crush and sieve to obtain calcined magnesium oxide powder with a particle size of -200 mesh.

[0077] 2) Take 5.4kg of solid ammonium nitrate and 1.48kg of magnesium sulfate heptahydrate, add water to fully dissolve, configure the solution volume to 10L, then add 1200g of lightly burned magnesium powder (solid-liquid ratio is 120g / L, NH 4 + :MgO is 2.5:1), put it into the reaction kettle, adjust the temperature of the water bath to 95°C, keep stirring at a speed of 120rpm during the reaction, and adjust the negative pressure to a relative vacuum of -0.098Mp, absorb the steamed ammonia with water, and leaching After 1 h, a solid-liquid mixed system was obtained.

[0078] 3...

Embodiment 3

[0089] Example 3 Preparation of high-purity magnesium oxide and fibrous magnesium hydroxide with magnesite

[0090] Experiment 1

[0091] Follow the steps below:

[0092] 1) Using the magnesite in Table 1 as raw material, calcining at 750°C for 2 hours to obtain light-burned magnesium powder, and then crushing and sieving to obtain calcined magnesia powder with a particle size of -200 mesh.

[0093] 2) Take 5.4kg of ammonium chloride solid and 0.61kg of ammonium sulfate, add water to fully dissolve, adjust the solution volume to 10L, then add 1400g of lightly burned magnesium powder (solid-liquid ratio is 140g / L, NH 4 + :MgO is 3.5:1), put it into the reaction kettle, adjust the temperature of the water bath to 90°C, keep the stirring speed at 180rpm during the reaction process, and adjust the negative pressure to a relative vacuum of -0.09Mp, absorb the evaporated ammonia with water, and leaching After 1.5 hours, a solid-liquid mixed system was obtained.

[0094] 3) Sucti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com