Hoisting machine for multiple components

A technology for hoisting machines and components, applied in the direction of traveling mechanism, transportation and packaging, load hanging components, etc., can solve the problems of low operating efficiency, slow down production process time of the assembly line, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

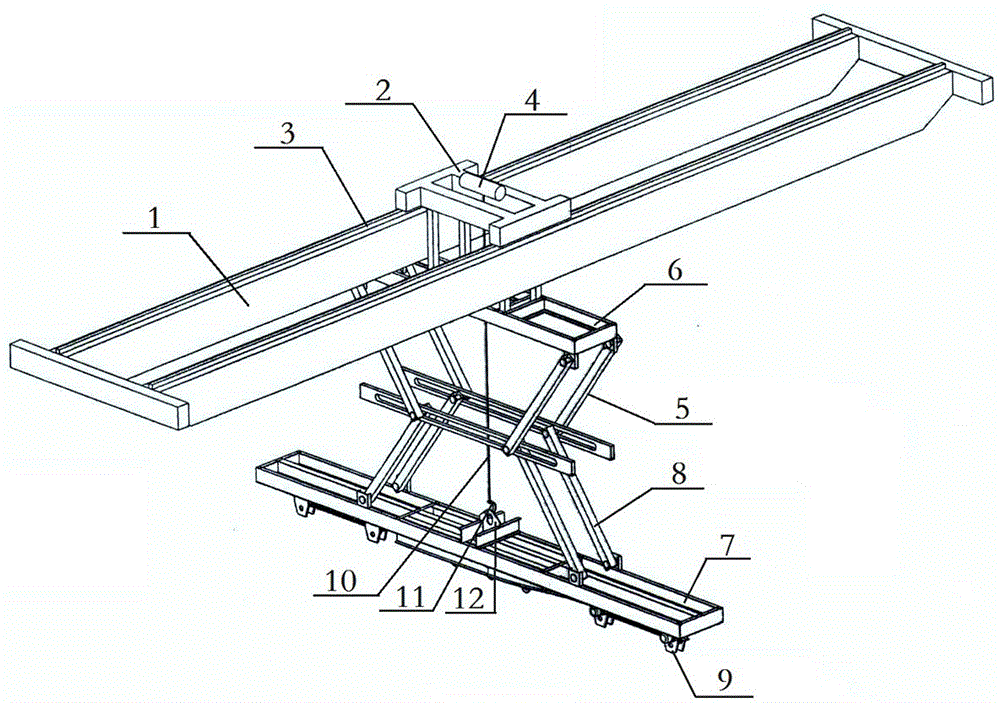

[0029] see figure 1 , the multi-component hoisting machine of the present invention comprises a walking trolley 2 mounted on a double-girder trolley 1 and capable of walking on the trolley rail 3, an upper end connected with the trolley 2 and a fixed lower end connected with a movable hoist 9 and a lifting balance frame fixed 5 and mobile spreader 9.

[0030] figure 1 The traveling trolley 2 in comprises the vehicle frame that is installed on the driving track and the lifting winch 4 that is installed and fixed on the vehicle frame and the driving motor that the walking trolley walks on the driving track.

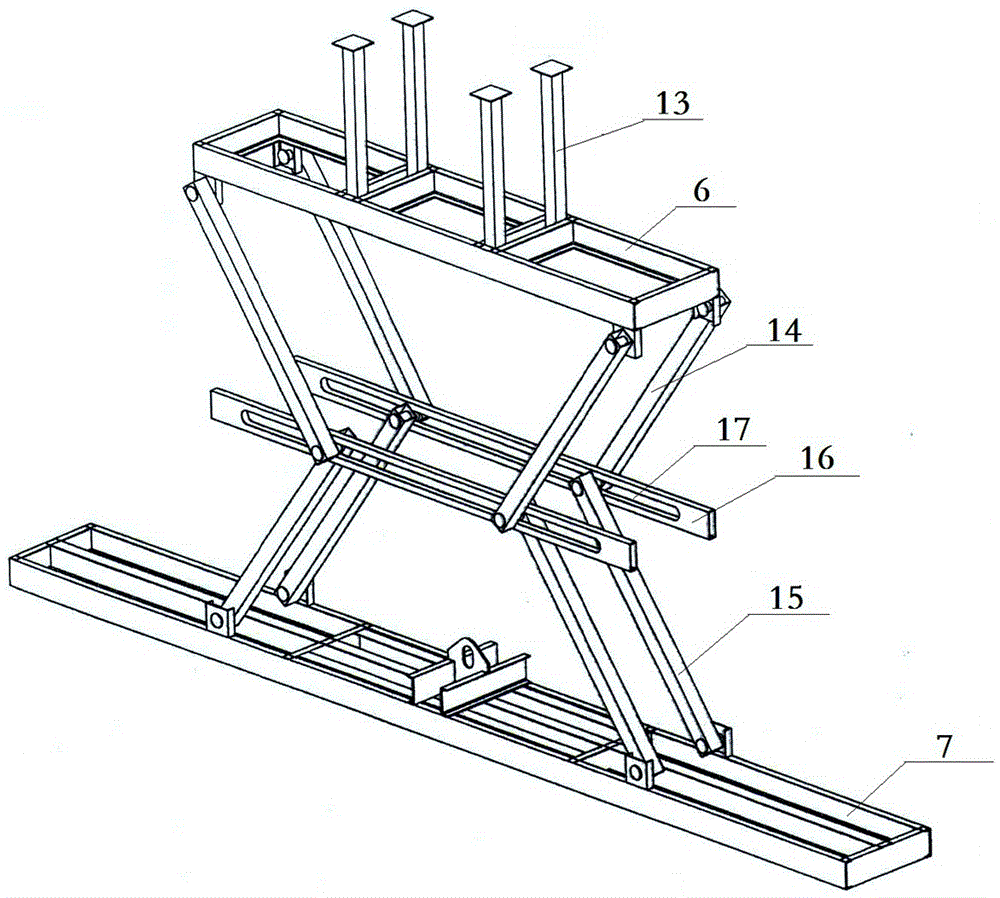

[0031] see figure 2 , the lifting balance frame 5 includes an upper frame 6 connected and fixed with the trolley frame, a lower frame 7 connected and fixed with the mobile spreader 9, and a four-bar linkage mechanism 8; the upper link 14 top of the four-bar linkage mechanism is connected with the upper The frame 6 is hinged, the bottom of the lower link 15 in the four-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com