Mobile phone motor double sided adhesive tape and foam pasting unit

A technology of double-sided tape and pasting machine, which is applied in the direction of sending objects, thin material handling, transportation and packaging, etc., to achieve the effects of high degree of automation, simple process, and saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

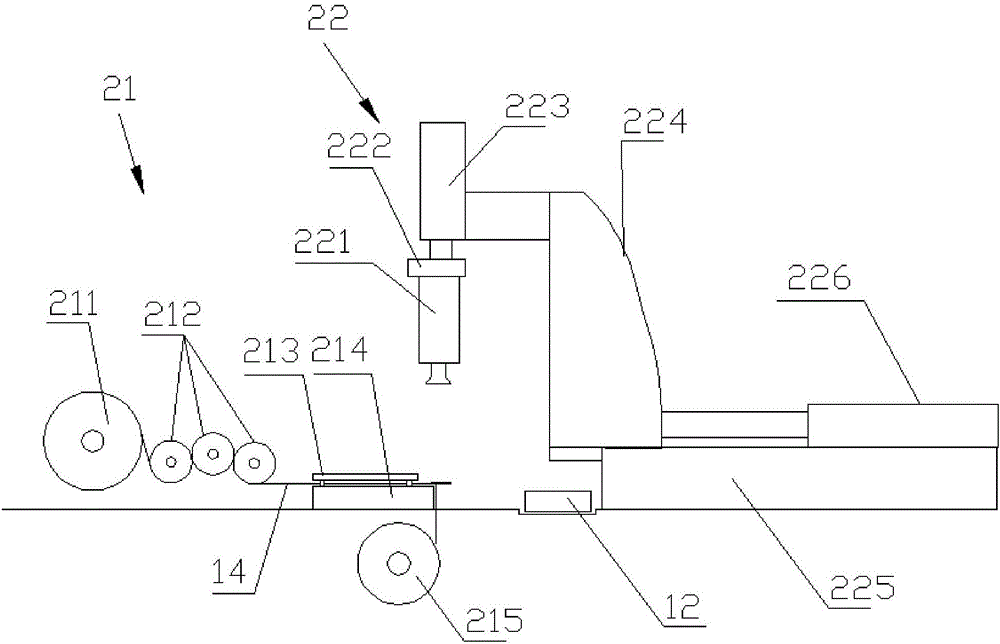

[0034] Such as figure 2 , image 3 , Figure, Figure 5 , Image 6 , Figure 7 As shown, a foam pasting machine 2 is fixed on a workbench 1, and the workbench 1 is also provided with a first transportation line 11 for transporting turnover bars. The mobile phone flat motor is mounted on the turnover bar 12. The lower casing of the motor is on the top, and the upper casing is on the bottom. The foam 13 is attached to the lower casing of the motor. The foam 13 has a circular structure, one side of which is sticky. A plurality of foams 13 are regularly arranged on the release paper tape 14 to form a foam tape, which is rolled into a foam roll, which is convenient for construction operation. The number of foams 13 in each row is the same as the number of motors on the turnover strip 12.

[0035] The foam sticking machine 2 includes a foam feeding device 21 and a foam sticking device 22. The foam feeding device 21 includes a foam feeding mechanism and a foam separating mechanism. ...

Embodiment 2

[0040] Such as Picture 8 , Picture 9 , Picture 10 As shown, in order to facilitate fixing the motor inside the mobile phone, it is also necessary to paste double-sided tape 15 on the upper casing of the mobile phone motor. That is to say, after the process of the embodiment 1 is completed, the turnover bar 12 flows into the station of the double-sided tape sticking machine 3.

[0041] The double-sided tape 15 is also round and has double-sided adhesiveness. One side is pasted on the release paper tape 14 and the other side is pasted on the second release paper tape. The shape of the second release paper tape matches the shape of the double-sided tape 15. However, in order to be able to easily tear off the second release paper tape later, the release paper tape 14 may be designed with a tail wing structure. On the release paper tape 14, there are multiple rows of double-sided tapes 15 regularly arranged, and they are rolled into 15 rolls of double-sided tapes. The number of ...

Embodiment 3

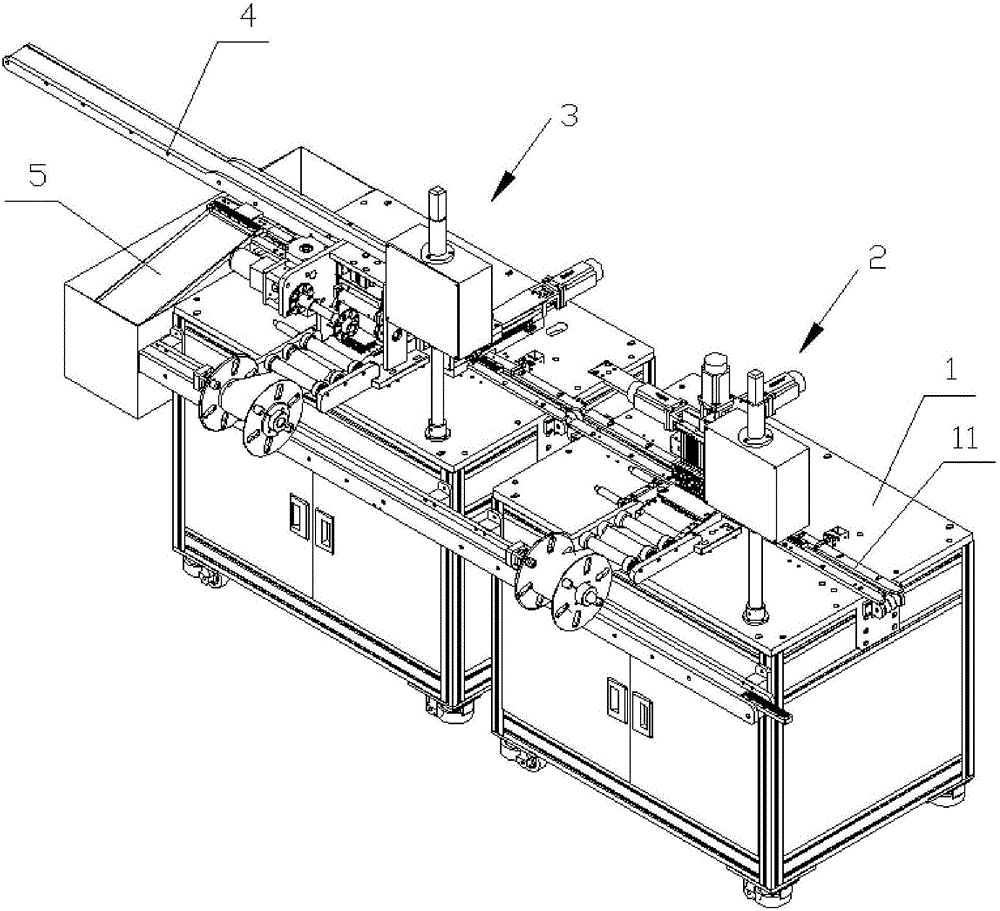

[0049] Such as figure 1 , Picture 11 As shown, a mobile phone motor foam and double-sided tape pasting unit includes the foam pasting machine 2 of Embodiment 1 and the double-sided tape pasting machine 3 of Embodiment 2. The foam pasting machine 2 and the double-sided tape pasting machine 3 are both fixed on the workbench 1, and the turnover strip 12 passes through the foam pasting machine 2 and the double-sided tape pasting machine 3 in turn. The workbench 1 is also provided with a third conveying line 5 for collecting the turnover strips 12 and a second conveying line 4 for collecting the motor with foam and double-sided tape. The second conveying pipeline 4 is parallel to the first conveying pipeline 11.

[0050] The fourth sliding seat 335 is arranged at the starting end of the second conveying line 4, and the moving path of the third sliding seat 334 on the fourth sliding seat 335 is perpendicular to the running path of the second conveying line 4. The second fixing seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com