Dosing and dispensing mechanism for sawdust or sealing compound

A sub-packaging and sealing technology, which is applied in measuring devices, measuring capacity, transportation and packaging, etc., can solve problems such as low production efficiency, impact on health, and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

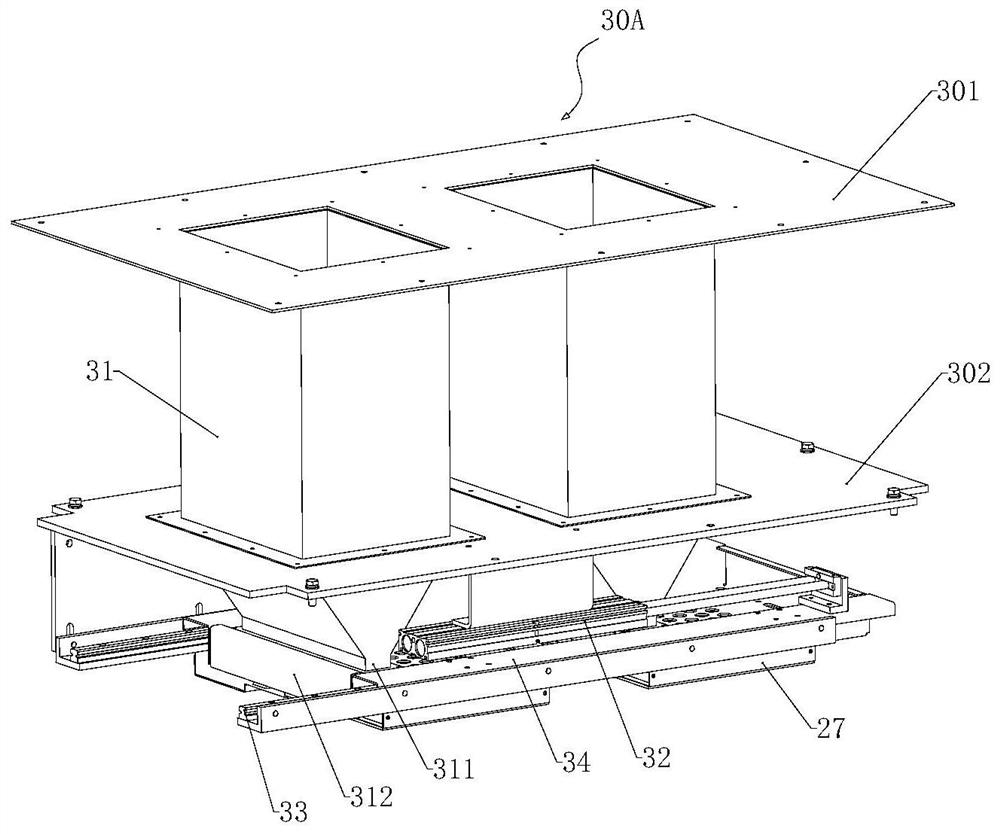

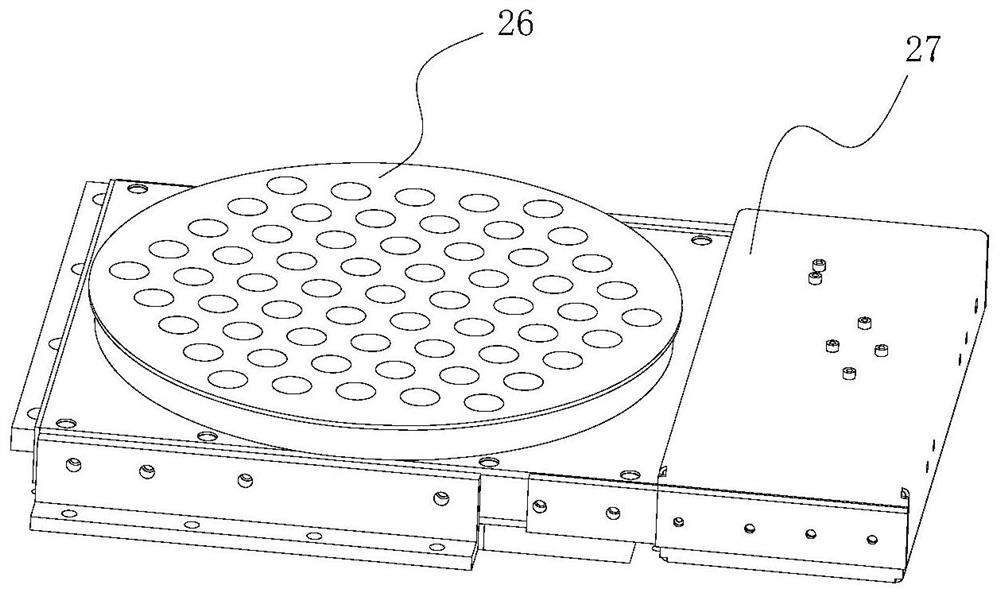

[0033] see figure 1 , figure 2 and image 3 , is a schematic structural diagram of a preferred embodiment of the present invention. In this preferred embodiment, the present invention provides a metering and dispensing mechanism 30A for sawdust or sealing medicine. The metering and dispensing mechanism 30A adopts a double-in and double-out structure, that is, feeding materials at two feed ports at the same time, The material is discharged from the two discharge points at the same time, and it can cooperate with the two inner cylinder cake units clamped by the execution end of the robot arm. The metering and dispensing mechanism 30A includes a bracket, which is also a vertically placed frame structure. The bracket can be provided with upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com