Staggered automatic deviation-rectifying device for belt conveyor

An automatic deviation correction device and belt conveyor technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of unsatisfactory practical application effects, excessive wear of conveyor belts, low deviation correction ability, etc., and achieve simple structure Reliable, anti-scratch, strong correction ability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

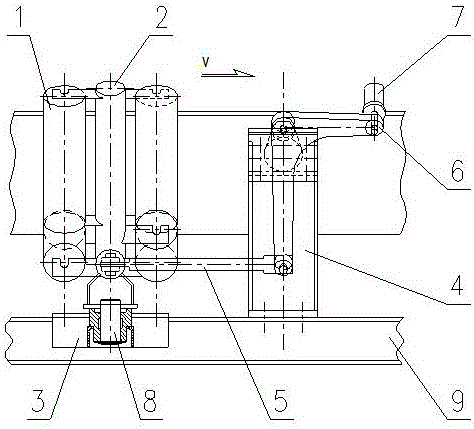

[0012] Referring to the accompanying drawings, a staggered automatic deviation correction device for a belt conveyor is composed of a power part, an execution part and a chassis, including staggered idler rollers 1, rotatable brackets 2, supporting chassis 3, and connecting rods. Mechanism base frame 4, connecting rod mechanism 5, load limiting device 6, retaining roller 7, rotating shaft 8, intermediate frame longitudinal beam 9, the power part is composed of retaining roller 7 and connecting rod mechanism 5, retaining roller 7 passes through load limiting device 6 and One end of the link mechanism 5 is connected, and the other end of the link mechanism 5 is connected with the rotatable bracket 2 through a hinge point, and the execution part is arranged alternately on both sides of the rotatable bracket 2 by four equal-diameter staggered idler rollers 1 , the connecting rod mechanism 5 and the rotatable bracket 2 are fixed on the linkage mechanism chassis 4 through the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com