Special-shaped bag packaging machine

A special-shaped bag, packaging machine technology, applied in the field of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

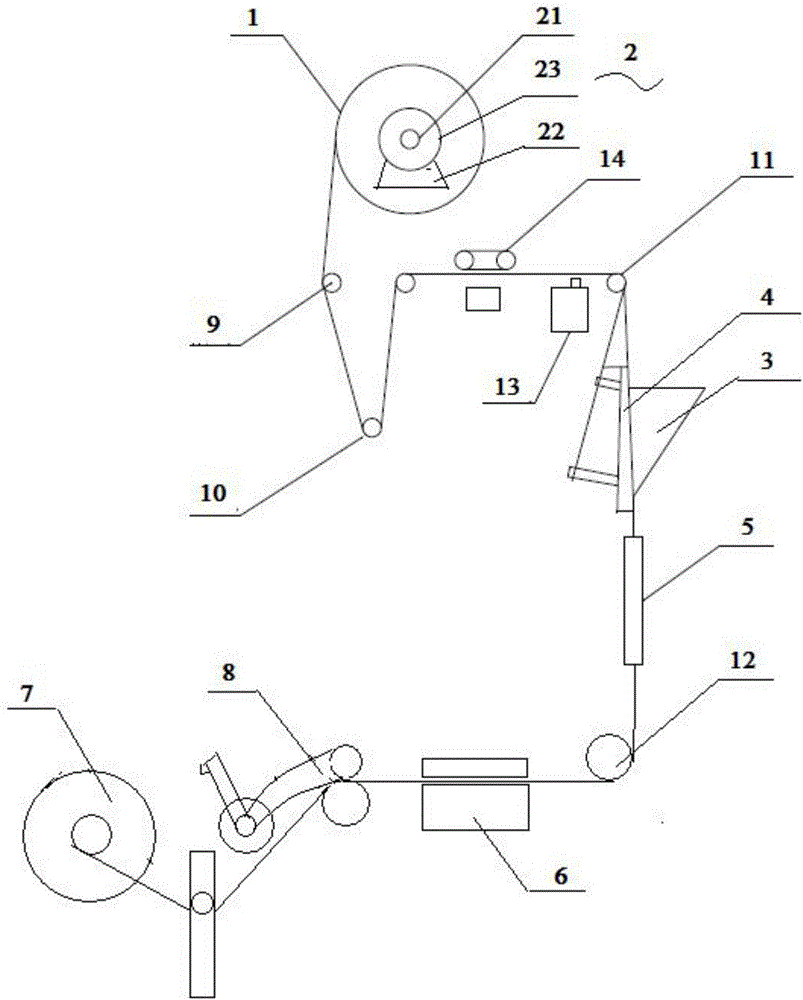

[0024] Such as Figure 1 to Figure 5 As shown, the special-shaped bag packaging machine of the present invention comprises: packaging film seat 2, blanking mechanism 3, forming mechanism 4, special-shaped bag mold 5, blanking die 6 and waste material recovery mechanism 7, will be installed on the packaging film seat 2 The packaging film 1 bypasses the film guide rod 9, the floating rod 10 and the film guide roller 11 in turn, and then passes through the forming mechanism 4, and is sent to the special-shaped bag mold 5 along the forming mechanism 4, and then changes direction through the reversing wheel 12 and passes through the punching machine. Die cutting 6, connecting the remaining packaging film waste to the drawing structure 8, and finally recycling it by the waste recycling mechanism 7;

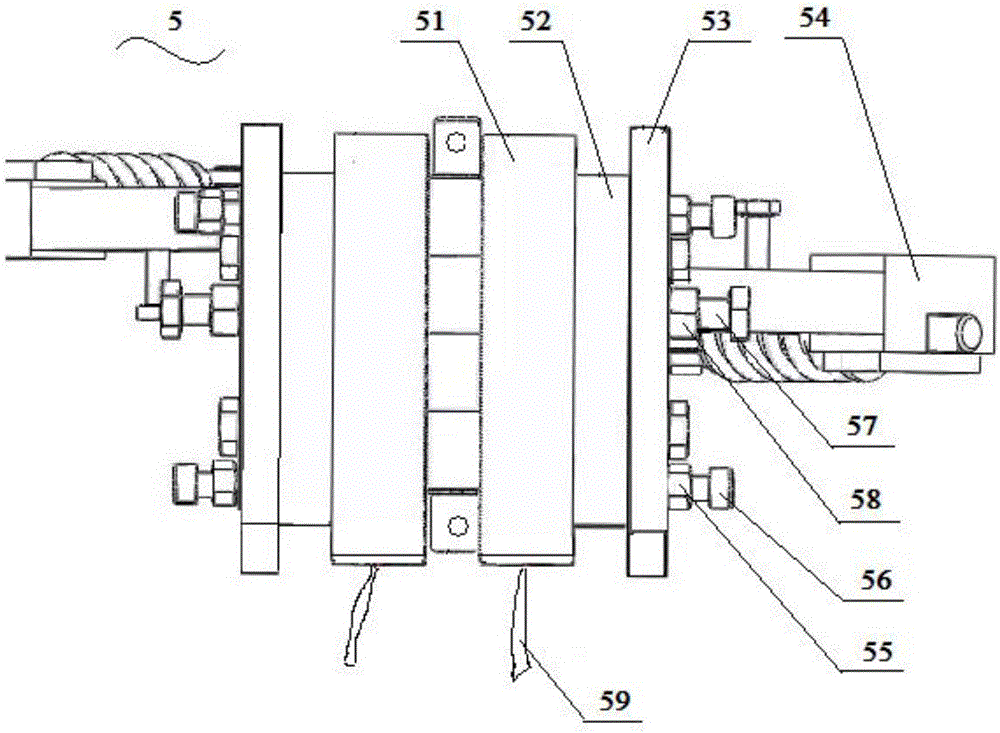

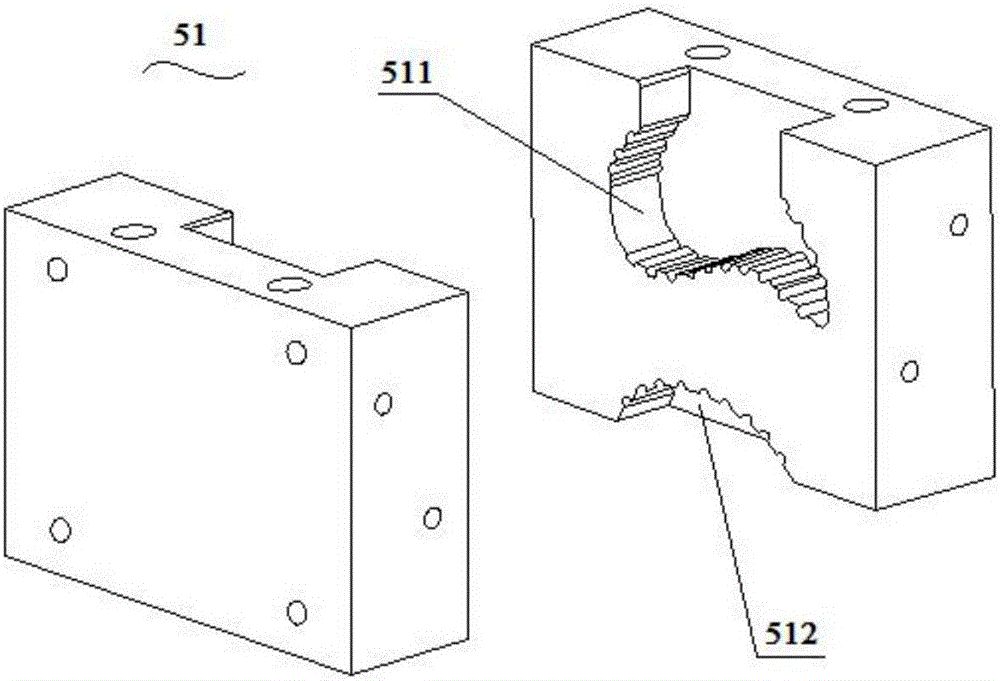

[0025] Described special-shaped bag mold 5 comprises: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com