Environment electric spray-propelled vessel

A technology of water jet propulsion and water jet propulsion, which is applied in the directions of propulsion components, ship propulsion, propulsion device engines, etc., can solve the problems of complex structure, unfavorable environmental protection, bottom suction and beaching, etc., and achieves flexible operation, low cost, and easy operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

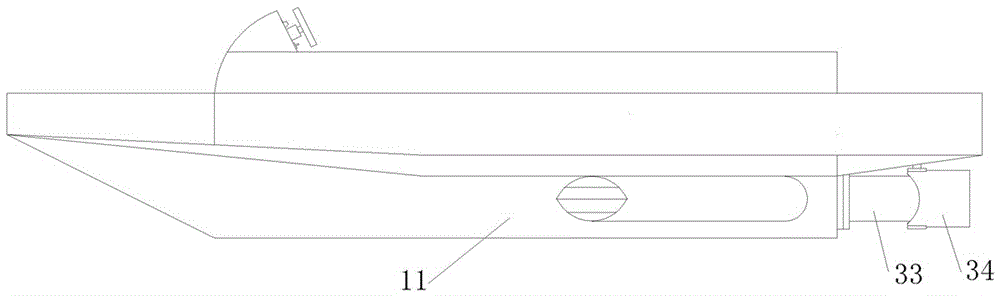

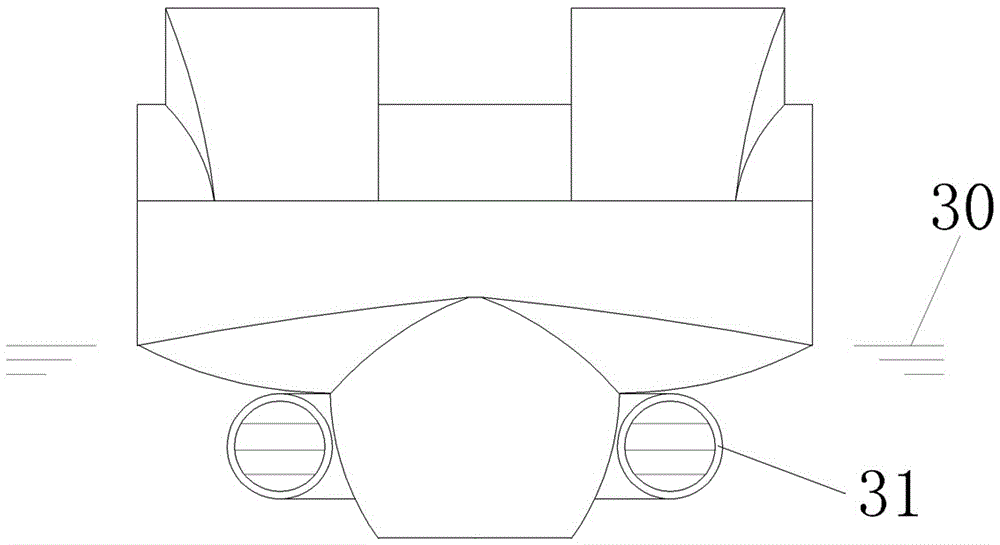

[0020] Referring to the accompanying drawings, the environmentally friendly electric water jet propulsion boat includes a hull, a console 4 installed on the hull, a DC electric device 5 and a water jet propeller 3; a steering gear is installed on the console, and the water jet propulsion The device includes a water suction pipe, a propeller main body and a water spray pipe 33, and the rear end of the water spray pipe is connected with a course adjustment control device, and the course adjustment control device includes a direction adjustment sleeve 34, a swing plate 41, a positioning vertical shaft 49, a copper Cover 43, copper sleeve gland 42, control riser 44, connecting rod 45, direction machine push-pull rod 46. The positioning vertical shaft 49 has two upper and lower ones, which are symmetrically distributed on the rear end pipe wall of the water spray pipe 33 and fixedly connected. The present embodiment is welding, and the copper sleeve 43 is set on the positioning vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com