Wet brake drive axle of scraper

A technology of wet brakes and drive axles, which is applied in the field of walking and braking systems and transmissions. It can solve the problems of high maintenance costs, low braking reliability, and short service life, achieve outstanding sealing effects, and reduce processing and assembly. The requirements of the process and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment, further illustrate the present invention.

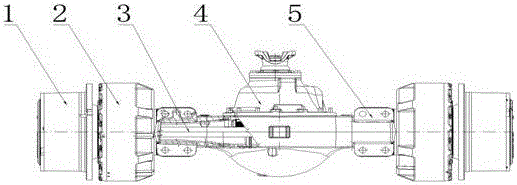

[0020] see figure 1 It can be known that a scraper wet brake drive axle of the present invention is composed of a wheel speed reduction mechanism 1, a wet brake 2, a half shaft 3, a main transmission assembly 4, and an axle housing 5. The wheel speed reduction mechanism 1 The outer splines of the wheel casing 6 on the upper wheel are connected with the inner splines of the dynamic friction plate 21 inside the wet brake 2, the wheel wet brake assembly is fixed on the axle housing 5 through a hollow shaft and stud bolts, and the main transmission assembly 4 passes through The stud bolts are fixed on the axle housing 5; the wheel side reduction mechanism 1 and the main transmission assembly 4 are connected through the half shaft 3.

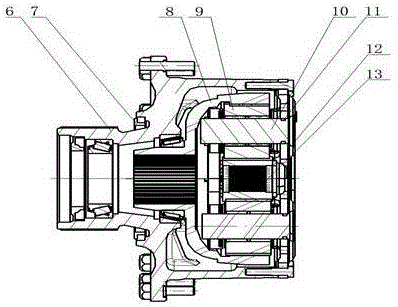

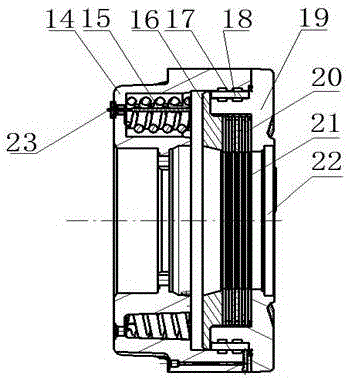

[0021] see figure 2 , image 3 It can be seen that the wet brake 2 is fixed on the axle housing 5 through the hollow shaft, the hub housing and the ring gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com