A kind of multi-layer co-extruded embossed film and its preparation method

A technology of co-extrusion and patterned film, which is applied in the field of multi-layer co-extruded patterned film and its preparation, can solve the problems of poor bearing performance of single-layer plastic structure, failure to satisfy consumers, poor air tightness, etc., and achieve low cost , various functions, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

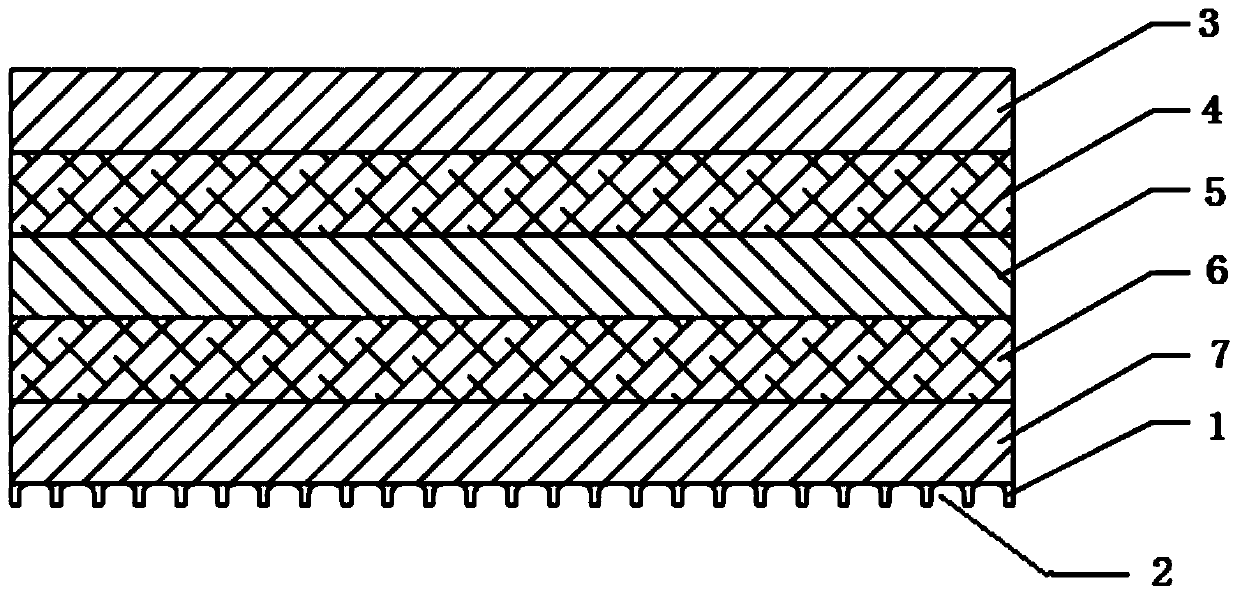

[0023] A multi-layer co-extruded textured film, the film is sequentially composed of a first PA layer, a second bonding PE layer, a third EVOH, a fourth bonding PE layer and a fifth PE layer.

[0024] The raw material of the first PA layer has a melting temperature of 230-260°C and a density of 1.08g / cm 3 nylon.

[0025] The raw materials of the second adhesive PE layer and the fourth adhesive PE layer include third LLDPE and fourth LLDPE with a weight ratio of 0.8:1. The third LLDPE has a melt index of 1.5g / 10min and a density of 0.914g / cm 3 The linear low density polyethylene; the fourth LLDPE has a melt index of 1.5g / 10min and a density of 0.916g / cm 3 of linear low density polyethylene.

[0026] The raw material of the third EVOH layer has a melt index of 5.7g / 10min and a density of 1.17g / cm 3 ethylene-vinyl alcohol copolymers.

[0027] The raw materials of the fifth PE layer include LDPE, MLLDPE and fifth LLDPE in a weight ratio of 3:6:1. The LDPE has a melt index of...

Embodiment 2

[0031] A multi-layer co-extruded textured film, the film is sequentially composed of a first PA layer, a second bonding PE layer, a third EVOH, a fourth bonding PE layer and a fifth PE layer.

[0032] The raw material of the first PA layer has a melting temperature of 250°C and a density of 1.18g / cm 3 nylon.

[0033] The raw materials of the second adhesive PE layer and the fourth adhesive PE layer include third LLDPE and fourth LLDPE with a weight ratio of 1.0:1. The third LLDPE has a melt index of 2.0g / 10min and a density of 0.922g / cm 3 The linear low density polyethylene; the fourth LLDPE has a melt index of 2.0g / 10min and a density of 0.920g / cm 3 of linear low density polyethylene.

[0034] The raw material of the third EVOH layer has a melt index of 5.7g / 10min and a density of 1.15g / cm 3 ethylene-vinyl alcohol copolymers.

[0035] The raw materials of the fifth PE layer include LDPE, MLLDPE and fifth LLDPE in a weight ratio of 5:4:1. The LDPE has a melt index of 2.0...

Embodiment 3

[0039] A multi-layer co-extruded textured film, the film is sequentially composed of a first PA layer, a second bonding PE layer, a third EVOH, a fourth bonding PE layer and a fifth PE layer.

[0040] The raw material of the first PA layer has a melting temperature of 235°C and a density of 1.12g / cm 3 nylon.

[0041] The raw materials of the second adhesive PE layer and the fourth adhesive PE layer include third LLDPE and fourth LLDPE with a weight ratio of 1.2:1. The third LLDPE has a melt index of 2.5g / 10min and a density of 0.920g / cm 3 The linear low density polyethylene; the fourth LLDPE has a melt index of 2.0g / 10min and a density of 0.924g / cm 3 of linear low density polyethylene.

[0042] The raw material of the third EVOH layer has a melt index of 5g / 10min and a density of 1.19g / cm 3 ethylene-vinyl alcohol copolymers.

[0043] The raw materials of the fifth PE layer include LDPE, MLLDPE and fifth LLDPE in a weight ratio of 3:5:1. The LDPE has a melt index of 1.8g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com