Bottle cap marking method through fiber laser and bottle cap manufactured through method

A fiber laser and laser marking technology, which is applied in the field of bottle caps, can solve problems such as fuzzy QR codes, unrecognizable QR codes, and inability to mark QR codes in bottle caps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

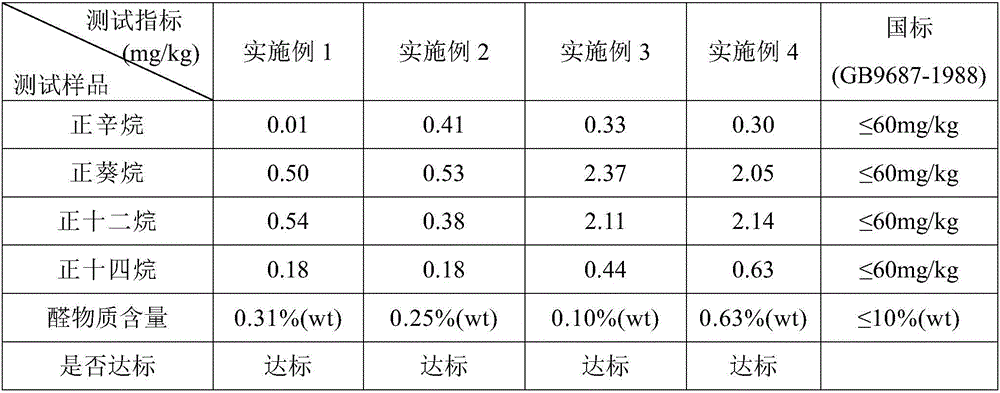

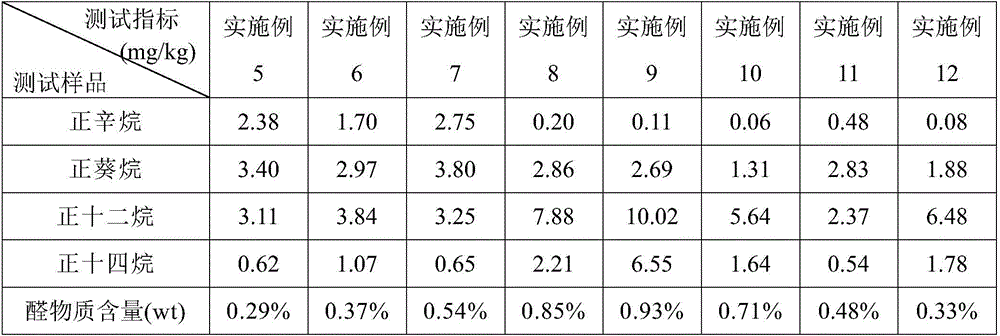

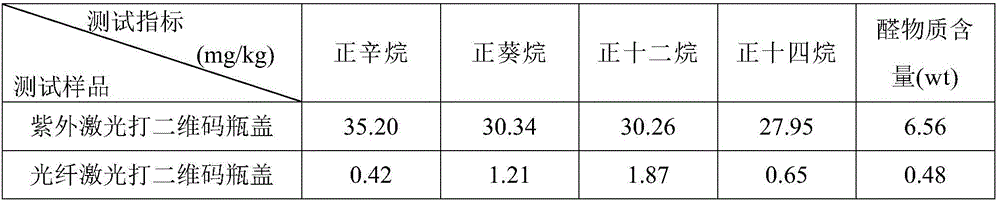

Examples

Embodiment 1

[0057] The method for marking bottle caps with fiber laser in an embodiment of the present invention uses infrared fiber lasers to mark the bottle caps. The specific method includes the following steps:

[0058] Masterbatch preparation steps: dry blending thermoplastics, additives and laser additives in a high-speed mixer, and then put them in a twin-screw extruder through melt extrusion, cooling, and pelletizing to make a masterbatch. The first zone temperature is 170℃, the second zone is 190℃, the third zone is 215℃, the fourth zone is 220℃, and the fifth zone is 215℃. The residence time in each zone is 1 to 2 minutes, and the pressure is 15Mpa; of course, double The screw extruder can also be replaced by a single-screw extruder or a multi-screw extruder, and the high-speed mixer can also be replaced by a low-speed mixer, which is not specifically limited in this embodiment.

[0059] Bottle cap preparation step: put the masterbatch prepared in the masterbatch preparation step int...

Embodiment 2

[0063] The method for marking bottle caps with fiber laser in an embodiment of the present invention uses infrared fiber lasers to mark the bottle caps. The specific method includes the following steps:

[0064] Masterbatch preparation steps: dry blending thermoplastics, additives and laser additives in a high-speed mixer, and then put them in a twin-screw extruder through melt extrusion, cooling, and pelletizing to make a masterbatch. The temperature in zone one is 170℃, zone two is 190℃, zone three is 215℃, zone four is 220℃, zone five is 215℃, the residence time in each zone is 1-2 minutes, and the pressure is 15Mpa;

[0065] Bottle cap preparation step: put the masterbatch prepared in the masterbatch preparation step into a compression molding equipment that has been equipped with a special mold for bottle cap manufacturing to perform compression molding, to obtain a bottle cap to be laser marked;

[0066] Laser marking step: focusing the infrared fiber laser on the bottle cap to...

Embodiment 3

[0069] The method for marking bottle caps with fiber laser in an embodiment of the present invention uses infrared fiber lasers to mark the bottle caps. The specific method includes the following steps:

[0070] Masterbatch preparation steps: dry blending thermoplastics, additives and laser additives in a high-speed mixer, and then put them in a twin-screw extruder through melt extrusion, cooling, and pelletizing to make a masterbatch. The temperature in zone one is 170℃, zone two is 190℃, zone three is 215℃, zone four is 220℃, zone five is 215℃, the residence time in each zone is 1-2 minutes, and the pressure is 15Mpa;

[0071] Bottle cap preparation step: put the masterbatch prepared in the masterbatch preparation step into a compression molding equipment that has been equipped with a special mold for bottle cap manufacturing to perform compression molding, to obtain a bottle cap to be laser marked;

[0072] Laser marking step: focusing the infrared fiber laser on the bottle cap to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com