PVC wallboard production equipment

A production equipment and wallboard technology, applied in the field of PVC wallboard production equipment, can solve the problems of low cutting precision and unsatisfactory effect, and achieve the effect of high processing precision, small error and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the present invention will be described in detail below with reference to the accompanying drawings and in combination with the embodiments.

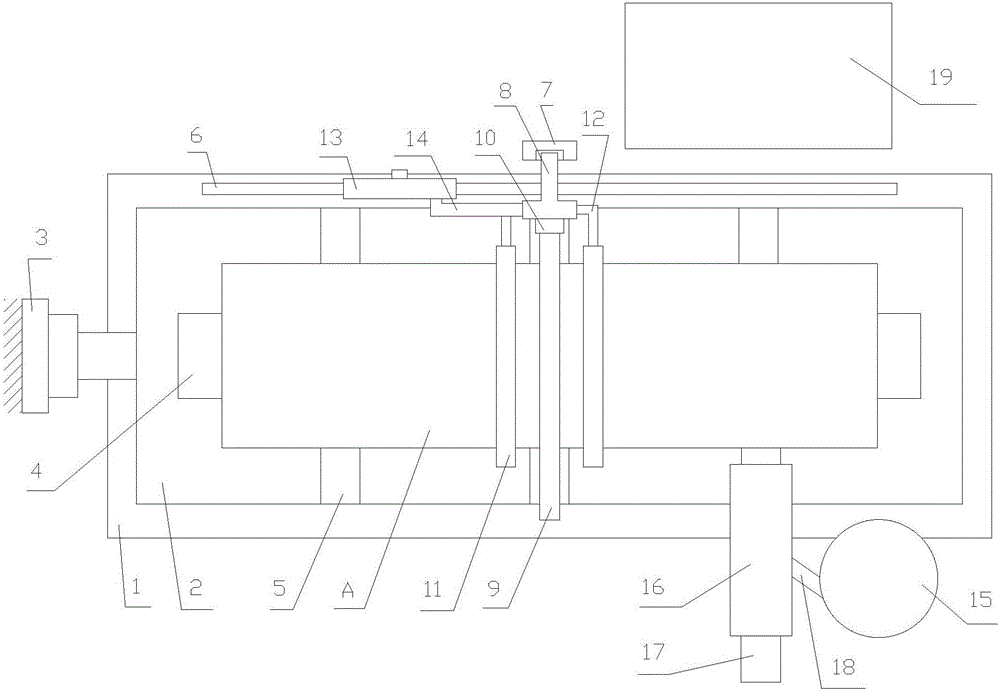

[0019] refer to figure 1 :

[0020] A PVC wallboard production equipment proposed by the present invention includes a processing table 1, a processing board 2, a power mechanism 3, and a cutting mechanism.

[0021] The processing table 1 is provided with guide rails along its length direction.

[0022] The processing plate 2 is movably installed on the guide rail. The upper surface of the processing plate 2 is provided with an accommodating groove 4 for accommodating the PVC wallboard. The accommodating groove 4 is arranged along the length direction of the processing table 1. The upper surface of the processing plate 2 is also provided with multiple A cutting passa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com