Online detection device for performance parameters of numerical control knife rest

A detection device and tool holder technology, applied in measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc., can solve the problems of manual replacement, low detection efficiency, single detection method, etc., and achieve strong applicability and automation. Easy and flexible detection and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is described in detail below in conjunction with accompanying drawing:

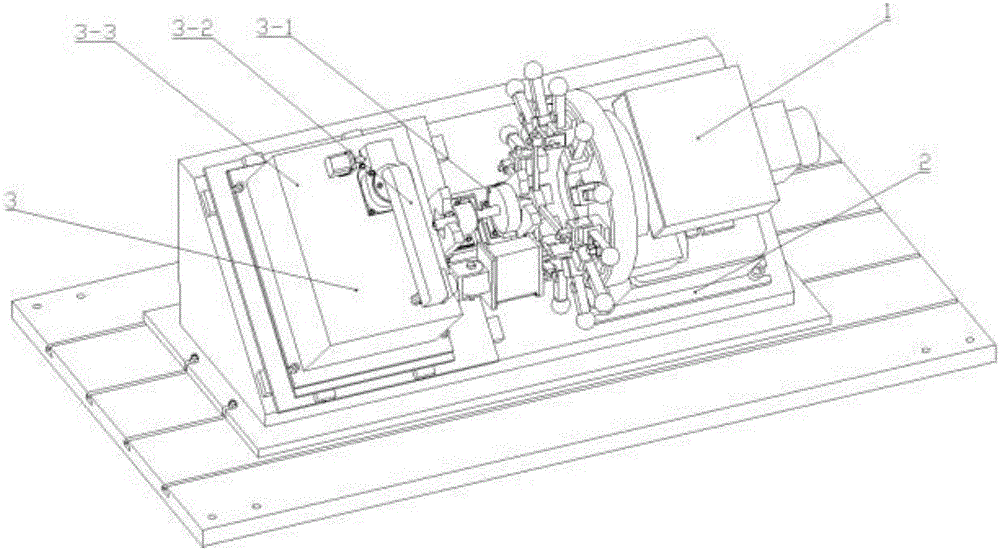

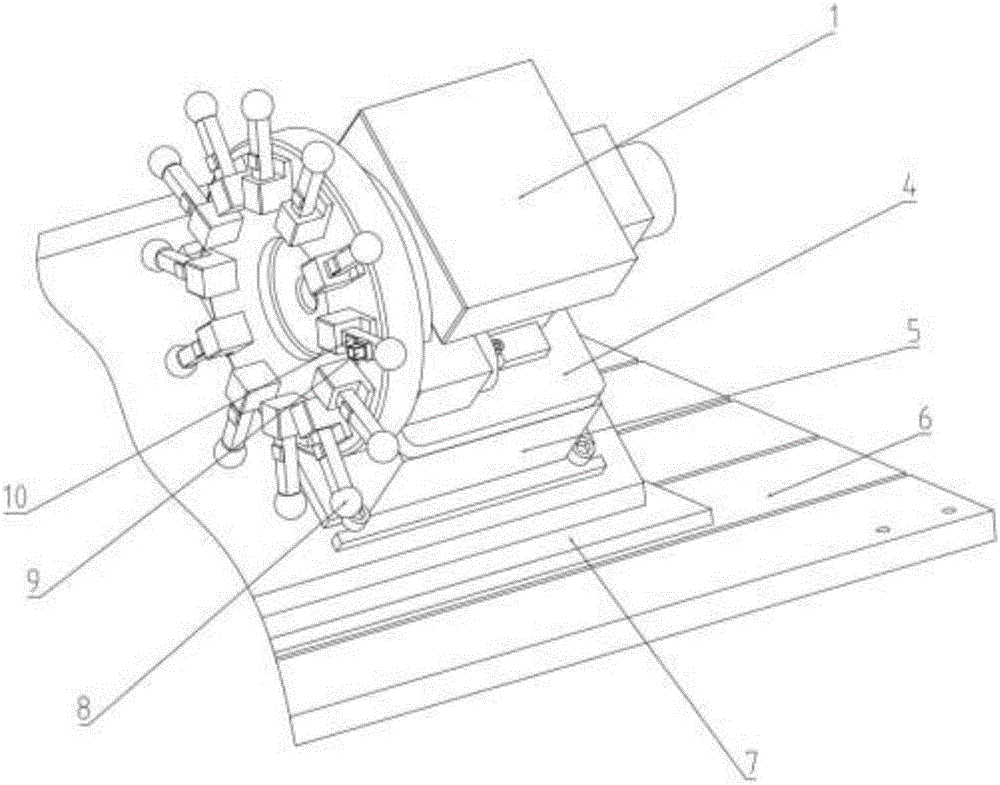

[0047] refer tofigure 1 , the tool holder performance parameter online detection device includes a servo tool holder 1, an installation platform 2 and a tool holder performance parameter online detection device 3.

[0048] refer to figure 2 , the installation platform 2 includes a knife rest backing plate 4, a knife rest base 5, a horizontal iron 6 and an inclined bed 7, and its function is to realize the installation and fixing of the knife rest. The servo tool holder 1 is connected with the tool holder backing plate 4 below by bolts, the tool holder backing plate 4 is fixed with the top of the tool holder base 5, and the tool holder base 5 is fixed on the right half of the inclined bed 7 by bolts , the inclined bed 7 is fixed on the horizontal iron 6.

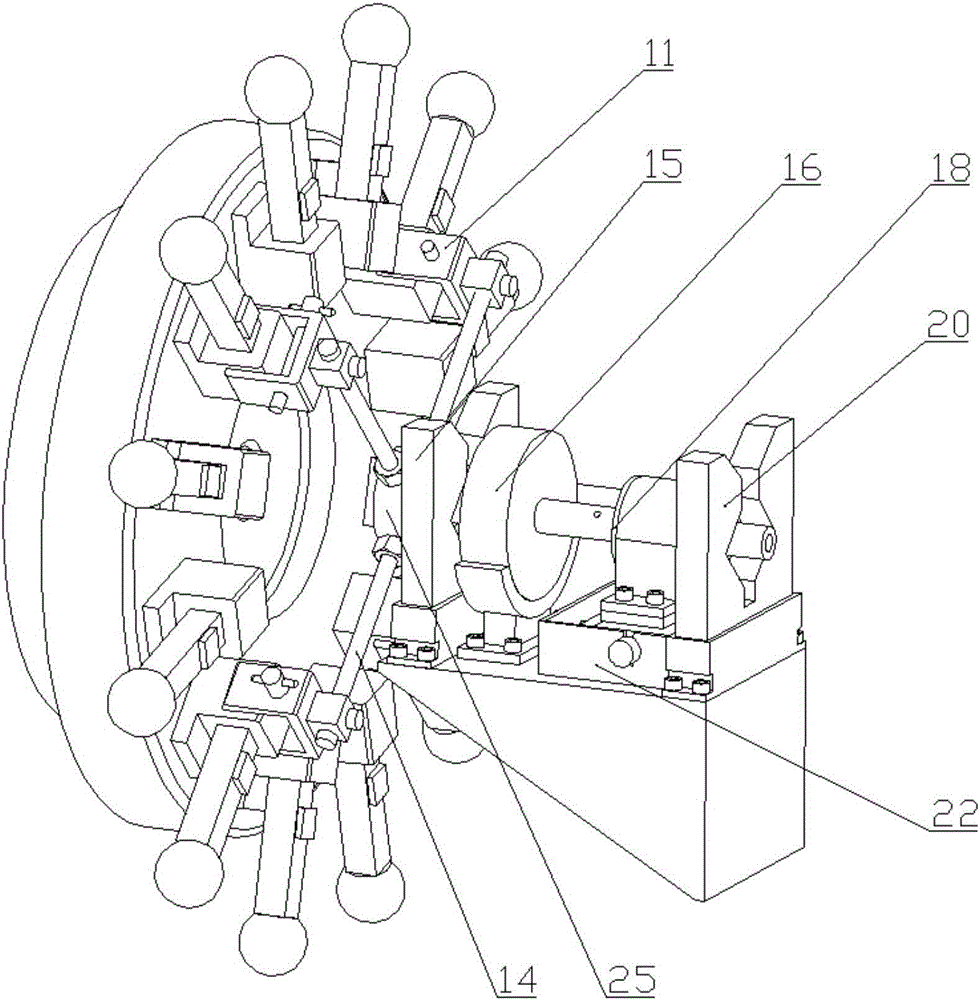

[0049] The on-line detection device 3 for the performance parameters of the knife rest is composed of three parts: the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com