Turning blade service life comparison method

An insert and turning technology, applied in the field of turning insert service life comparison, can solve the problems of poor economy, low efficiency, serious tool wear, etc., to reduce costs, improve test efficiency, and save test time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

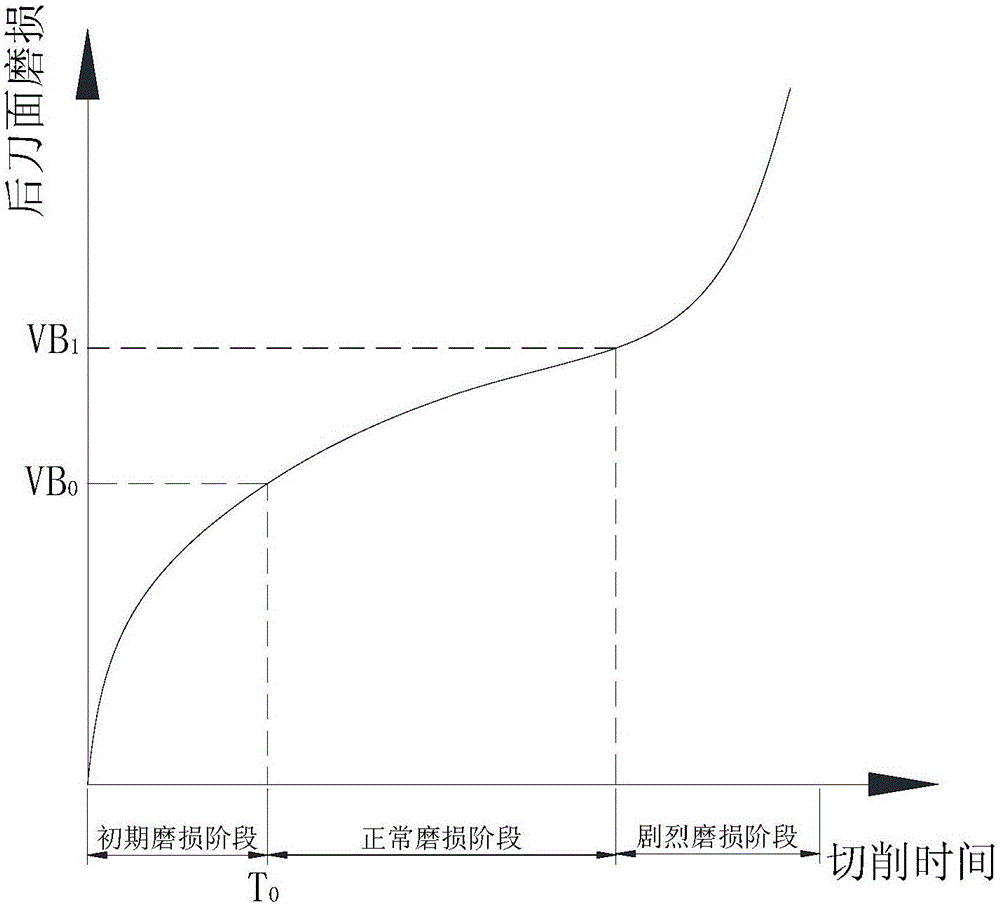

[0026] Turning blade service life comparison method of the present invention, compare the service life length of each turning blade by comparing the initial wear rate K of each turning blade, the initial wear rate K 0 Obtained by the following steps:

[0027] S1. Set initial wear cutting time T 0 ;

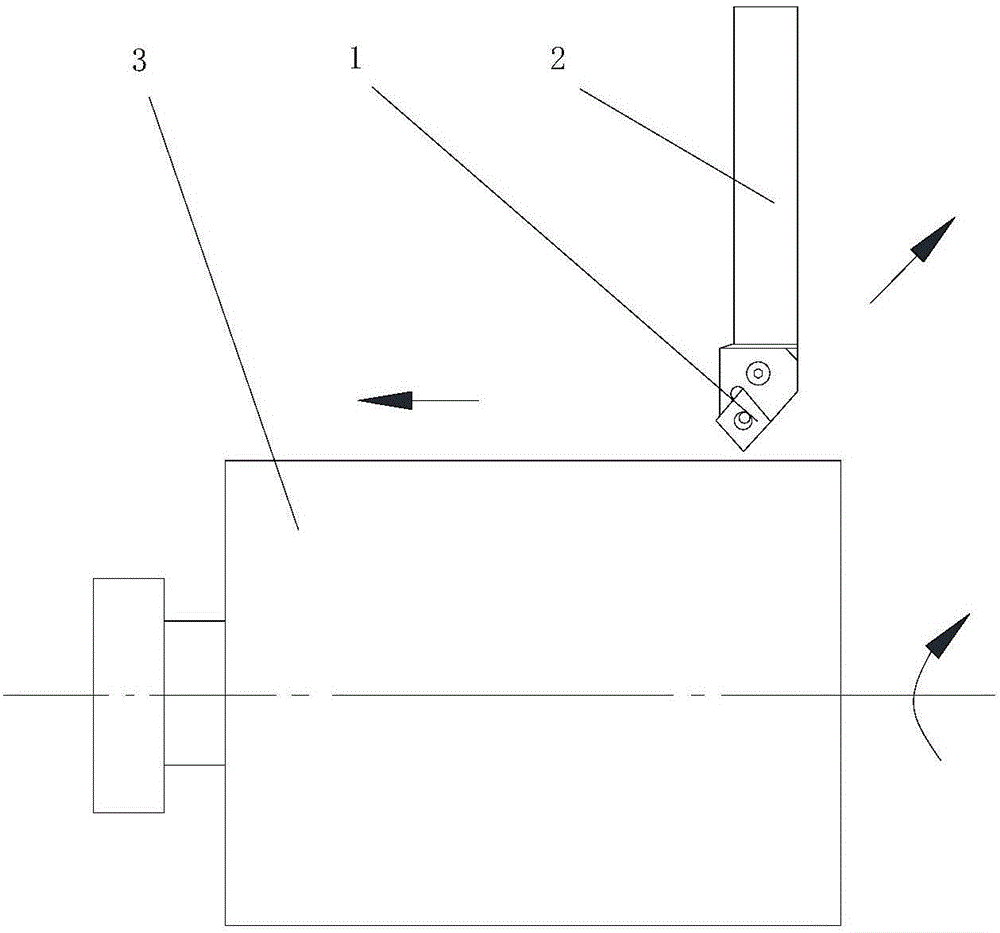

[0028] S2. Turn on the cutting machine tool, and cut the workpiece according to the set cutting speed Vc, feed rate f and depth of cut ap;

[0029] S3, the cutting time reaches the initial wear cutting time T 0 back knife;

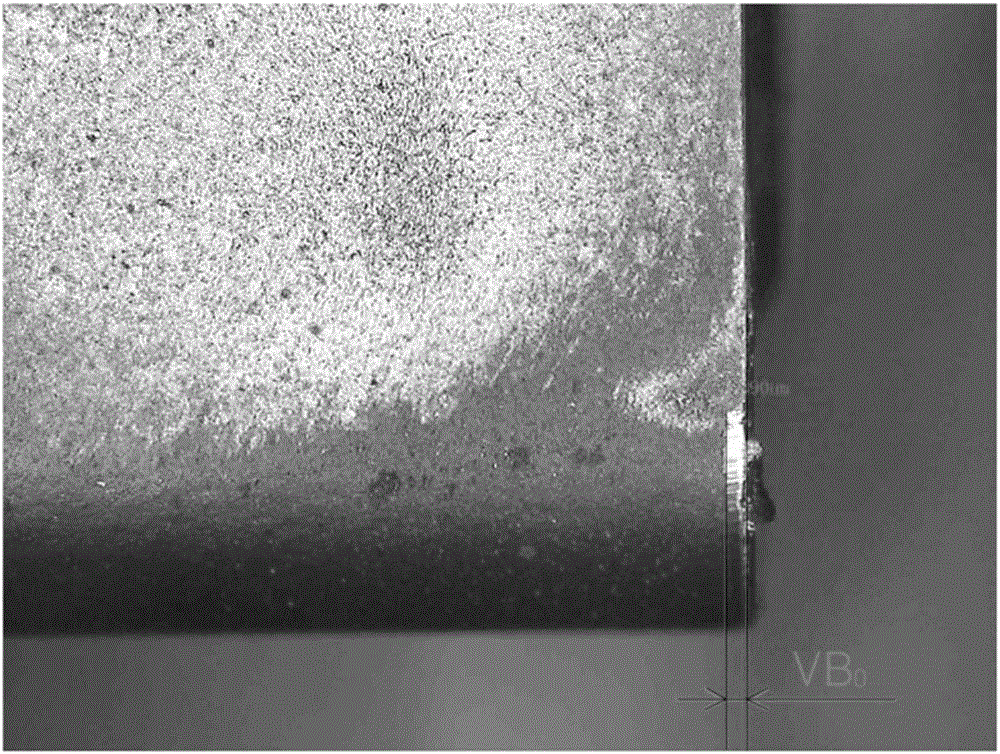

[0030] S4. Measure the initial wear value VB of the main flank surface of the turning insert 0 ;

[0031] S5, according to K 0 =VB 0 / T 0 Calculate the initial wear rate K of the turning insert 0 .

[0032] Make each turning insert 1 follow the same cutting parameters and the same initial wear cutting time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com