Circular loom

A circular loom, host technology, applied to the circular loom. It can solve the problems of increasing the use cost of limit rollers and affecting the efficiency of circular looms, and achieve the effects of reducing wear, alleviating impact and improving weaving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

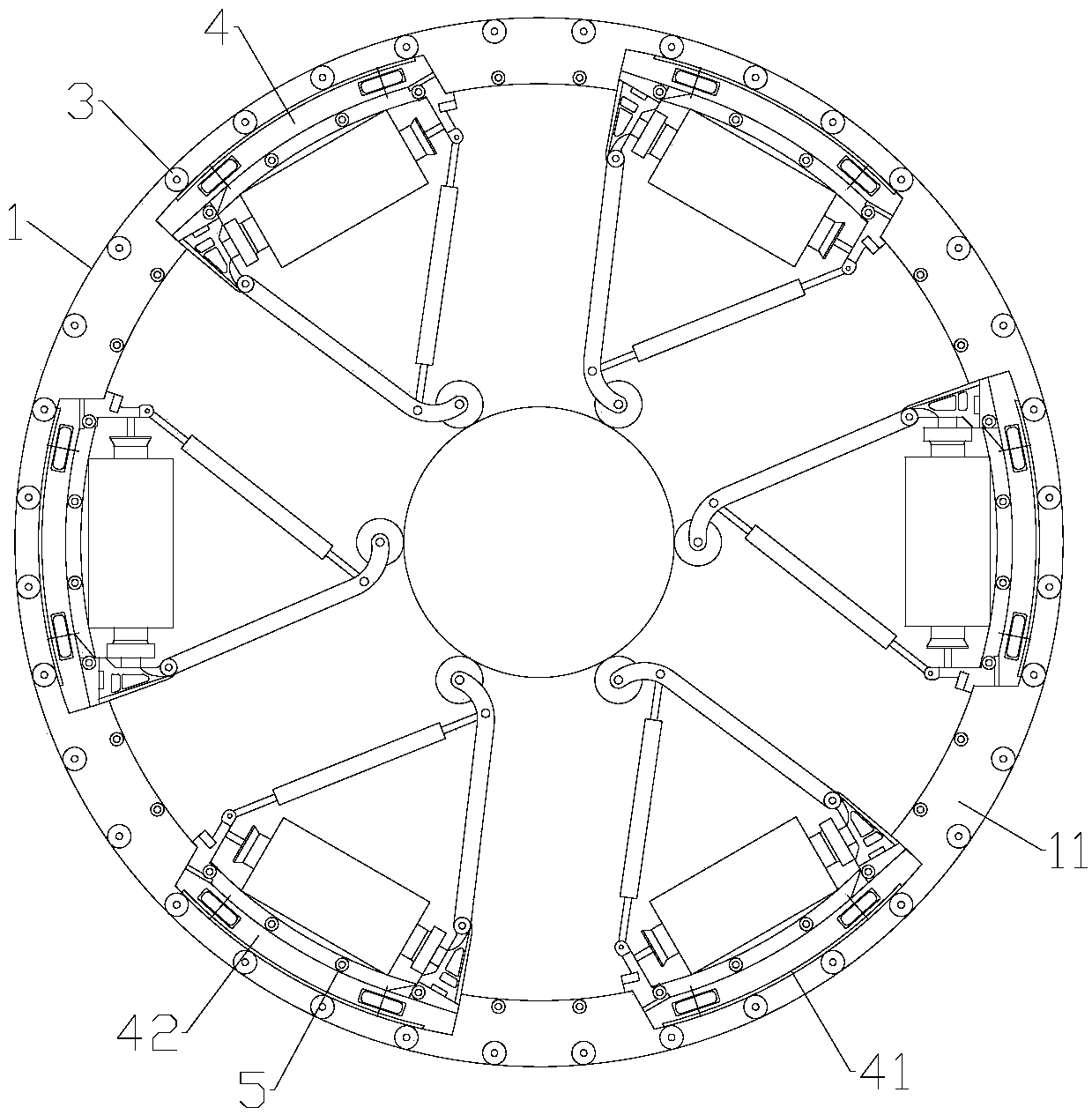

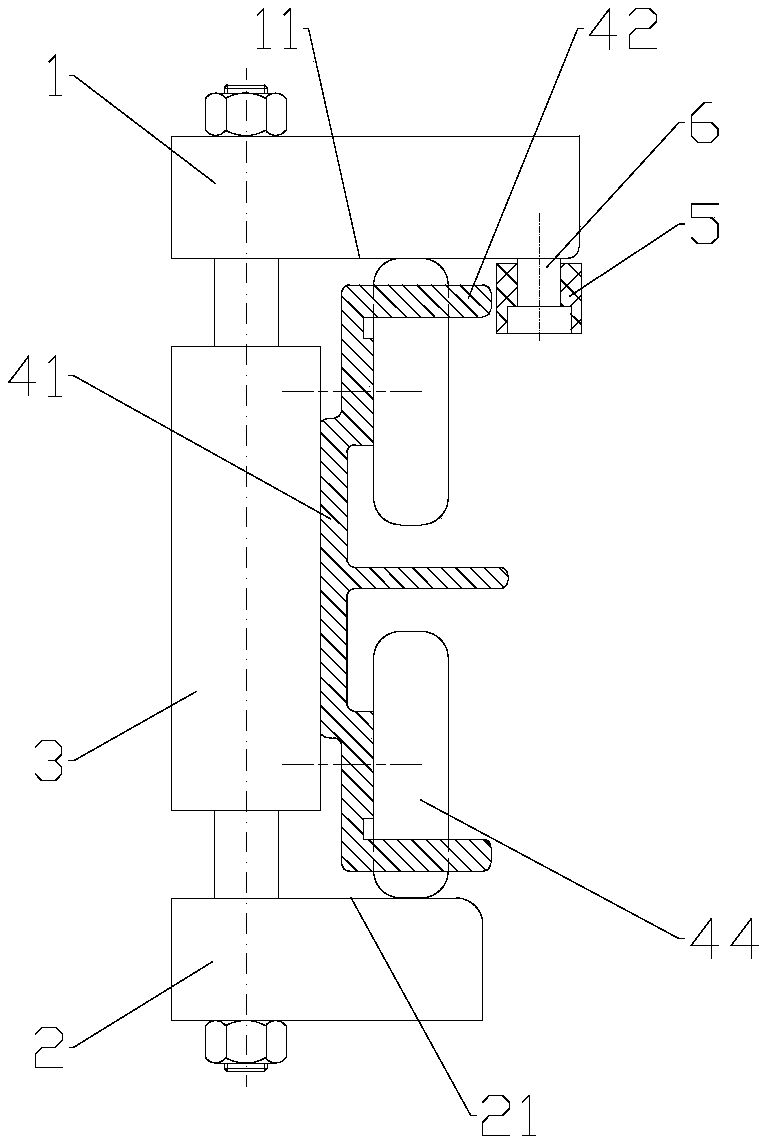

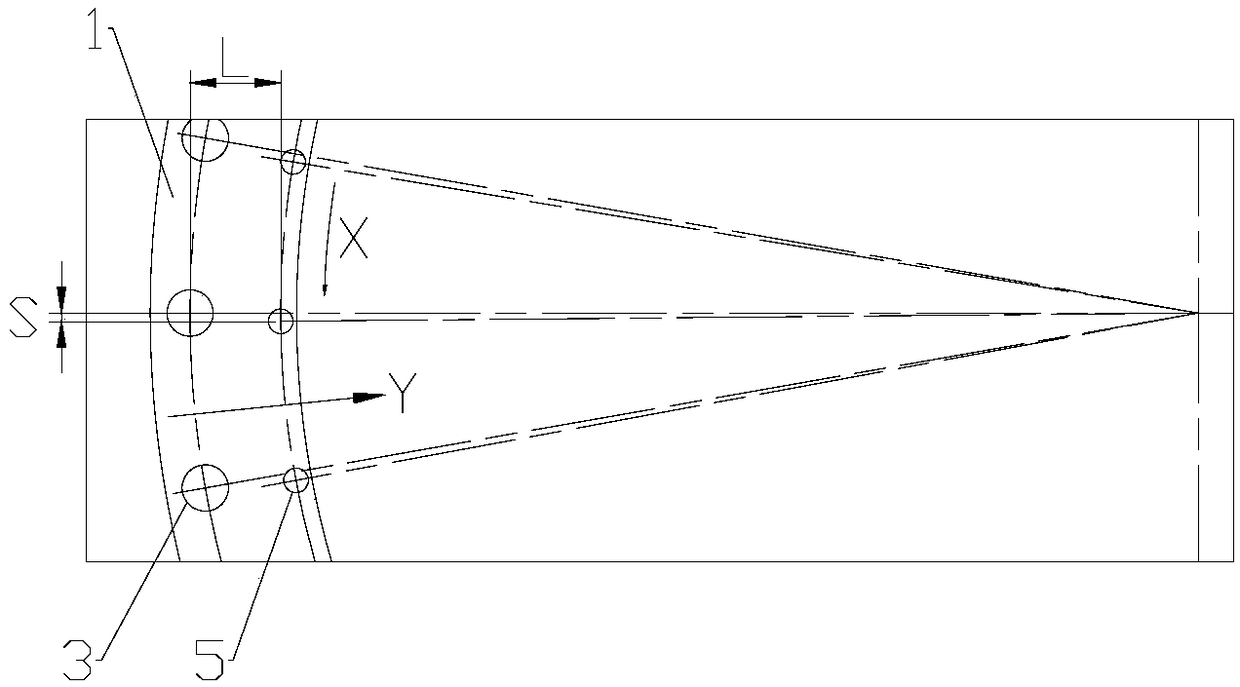

[0021] The invention provides a circular loom, comprising a frame, a main frame, a door ring assembly and a shuttle, and the main frame and the door ring assembly are arranged on the frame, such as figure 1 and figure 2 As shown, the door ring assembly includes an upper door ring 1, a lower door ring 2 and a plurality of rollers 3 connected to the upper door ring 1 and the lower door ring 2. The plurality of rollers 3 form a rolling track in a circle, and the host drives the shuttle 4 Make a circular motion along the rolling track. In the present embodiment, the shuttle 4 is provided with six and evenly distributed on the rolling track. The shuttle 4 includes a shuttle body 41, and the lower surface 11 of the upper door ring 1 and the upper surface 21 of the lower door ring 2 are On the radial plane, the lower surface 11 of the upper door ring 1 is provided with an anti-off roller 5 on the inner ring side of the running track of the shuttle 4, and the upper side of the shuttl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com