Maintenance-free rotating compensator

A rotary compensator, maintenance-free technology, applied in expansion compensation devices for pipelines, pipes/pipe joints/fittings, adjustable connections, etc., can solve the problem of increasing the maintenance workload of rotary compensator sealing performance and shortening the rotation compensation The service life of the device, the aggravation of the wear of the sealing packing, etc., achieve the effect of reducing the maintenance workload, small friction and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

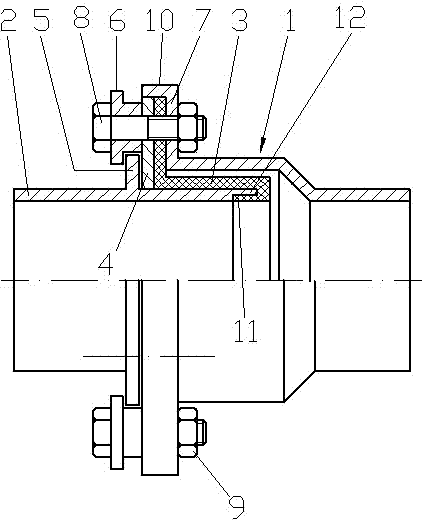

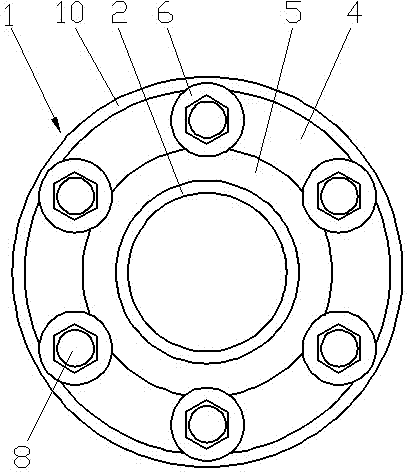

[0012] The specific embodiment of the present invention will now be described with reference to the accompanying drawings.

[0013] The structure of the maintenance-free rotary compensator includes an outer tube 1 and an inner tube 2. It is characterized in that a flange 5 is provided in the middle of the inner tube, and the right side of the flange is sequentially covered with a positioning ring 4, a sealing sleeve 3, and the sealing sleeve The pipe part shrinks radially on the outer circle of the inner pipe, and the pipe part of the sealing sleeve extends in the outer pipe. There is a gap between the pipe part of the sealing sleeve and the inner wall of the outer pipe. The flange extending radially at the left end is placed on the left side of the flange, and a plurality of bolts 8 pass through the positioning ring, the flange of the sealing sleeve and the flange, and the nut 9 at the left end of the bolt is tightened to compress the flange of the sealing sleeve On the flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com