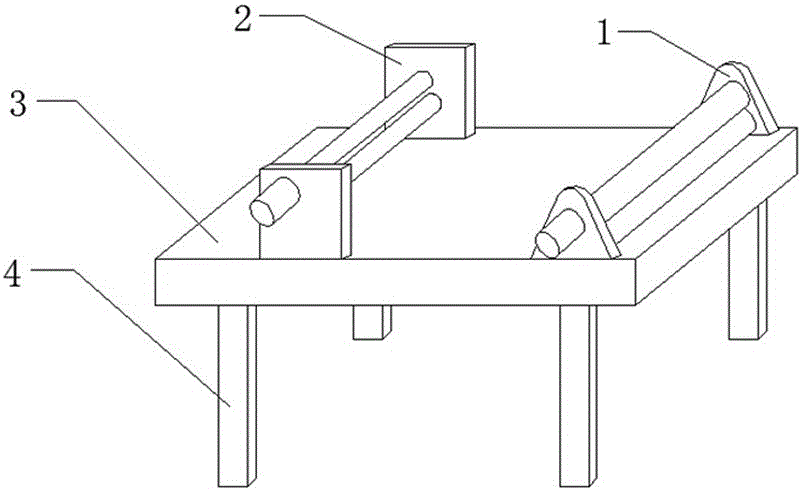

Machining device for plate electrode of welding equipment

A technology of processing equipment and welding equipment, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of discounted service life of welding projects, uneven welding quality, and difficult guarantee of parallelism, so as to avoid welding failure. Fix events, reduce production costs, and improve construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

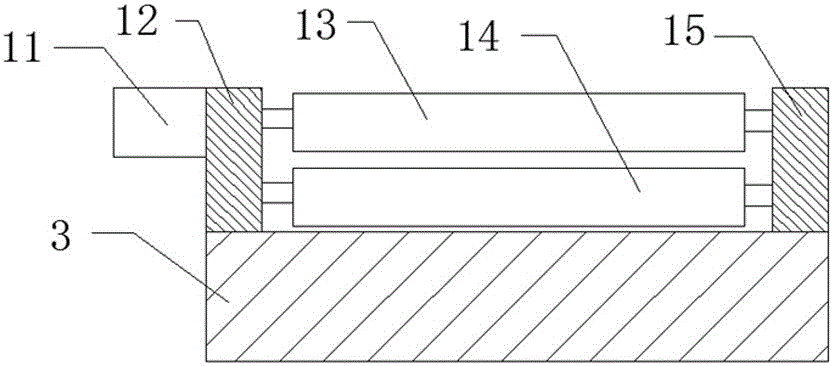

[0024] Specific implementation method: the user first puts the electrode plate material to be processed between the driving roller 13 and the driven roller 14, connects the present invention with an external power supply, and the external power supply transmits the electric energy to the motor one 11, and the electric motor one 11 transfers the electric energy Converted into mechanical energy, it drives the driving roller 13 to rotate. Due to the effect of friction, the driven roller 14 and the driving roller 13 rotate in the opposite direction, and then the electrode plate material to be processed is flattened. This design solves the problem of the original electrode plate processing equipment. The problem of deformation of the electrode plate improves the processing quality of the electrode plate, avoids the occurrence of weak welding in the welding project, improves the construction quality of the welding project, and reduces the production cost of the enterprise.

[0025] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com