racket automatic drilling machine

A drilling machine, fully automatic technology, applied in the direction of boring/drilling, drilling/drilling equipment, drilling templates for workpieces, etc., can solve the problem of not being suitable for large-scale industrial production and the quality of drilling is not easy Guarantee, cost a lot of labor productivity and other issues, to achieve the effect of compact structure, high drilling quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

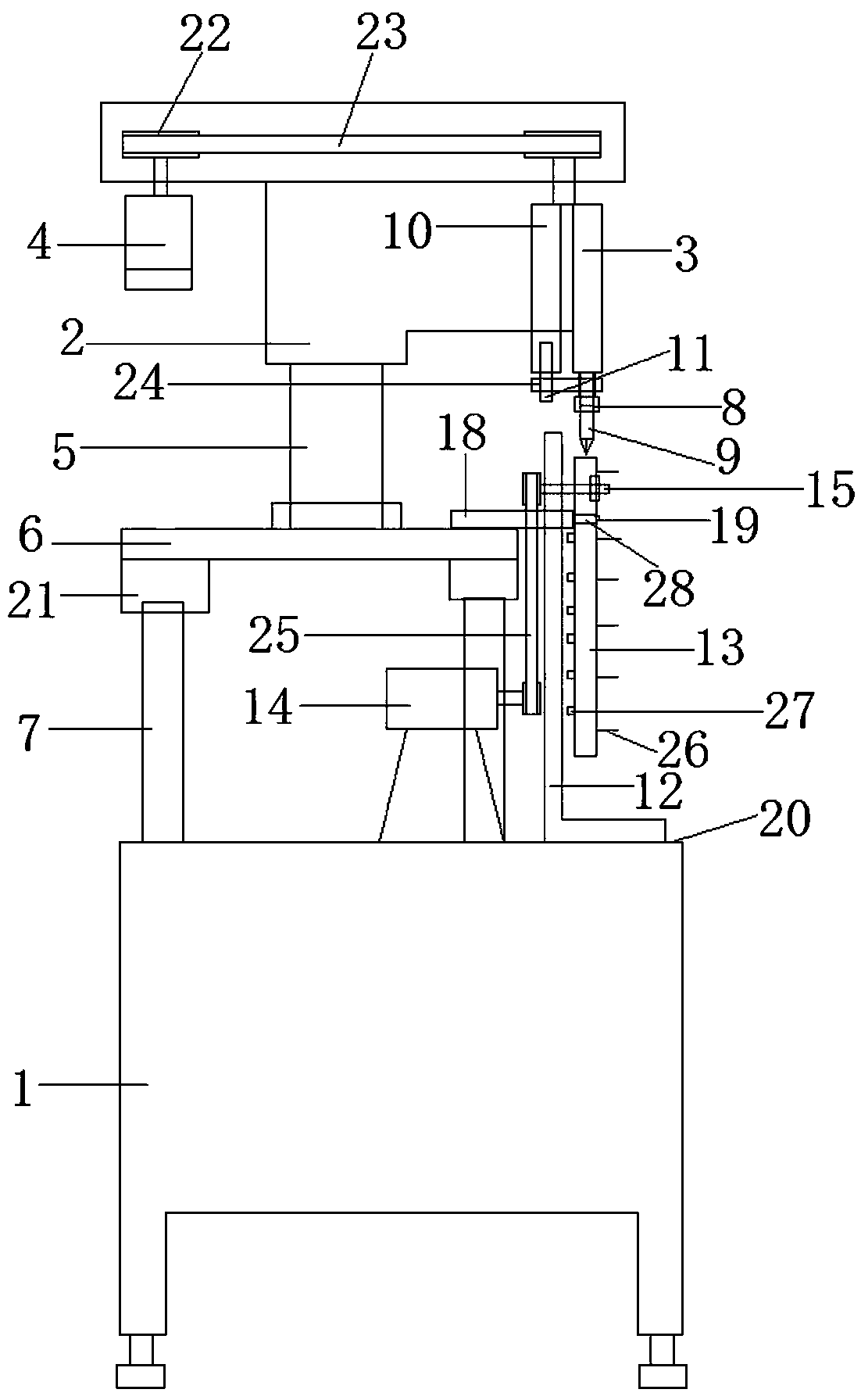

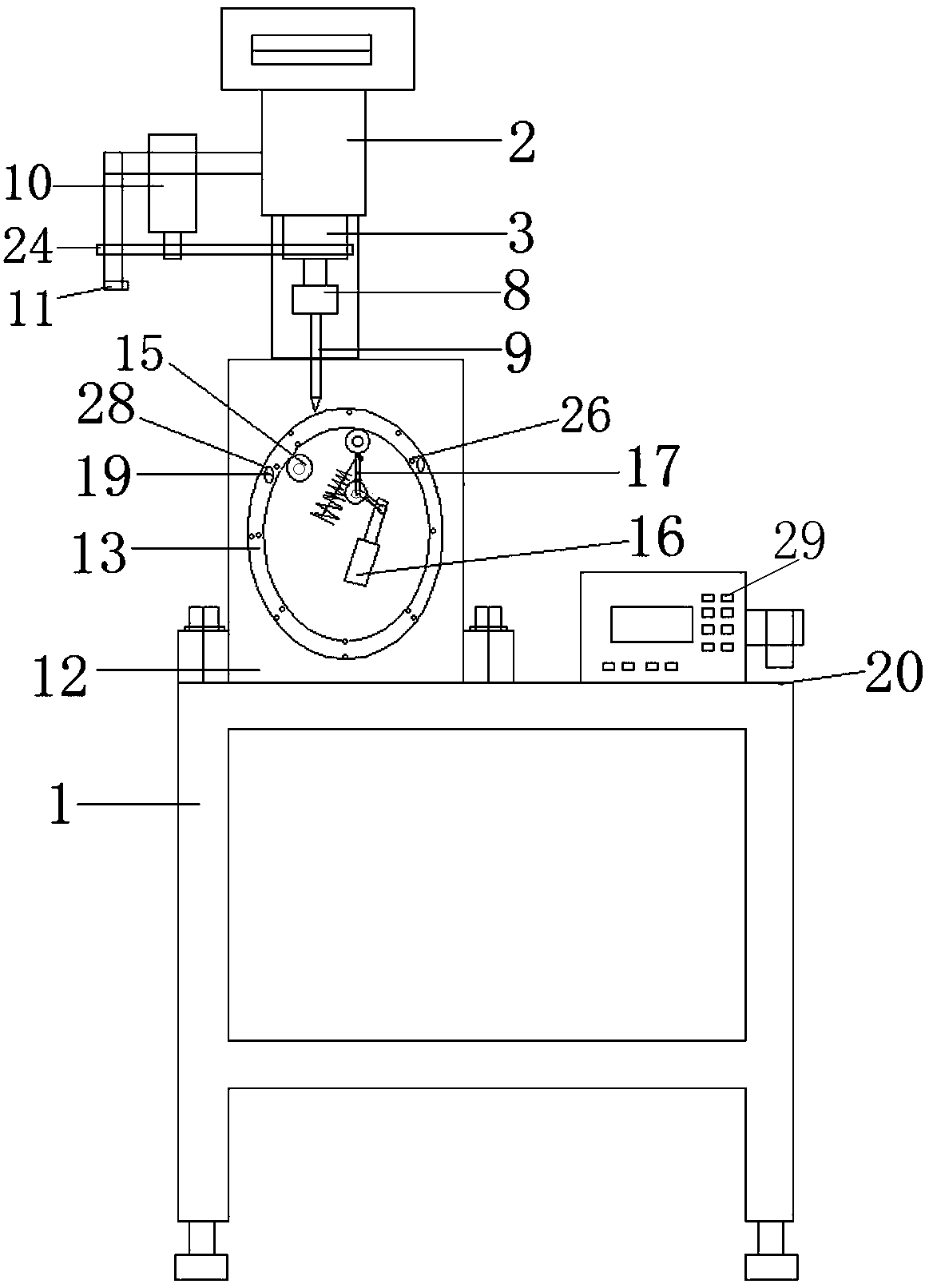

[0019] Refer to attached figure 1 , 2 , The racket automatic drilling machine includes frame 1, chassis 2, spindle 3, spindle drive motor 4, column 5, column mounting plate 6, support column 7, drill chuck 8, drill bit 9, spindle lifting cylinder 10, cylinder lifting Electromagnetic sensor 11, horizontal positioning plate 12, drilling mold 13, mold transmission motor 14, mold transmission wheel 15, mold indexing push cylinder 16, steering connecting rod 17, discharge cylinder 18 and air pressure discharge rod 19.

[0020] The top of the frame 1 is provided with a workbench 20, the cabinet 2 is installed on the top of the column 5, the column 5 is installed on the column mounting plate 6, the column mounting plate 6 is installed on the workbench 20 through four support columns 7, the column mounting plate 6 and Elastic shock-absorbing sleeve 21 is housed between the support columns 7, to eliminate vibration in the drilling process.

[0021] A main shaft transmission motor 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com