Continuous type full-automatic drilling machining equipment for charger shell bodies

A technology for processing equipment and chargers, which is applied in the direction of metal processing equipment, drilling/drilling equipment, boring/drilling, etc., and can solve problems such as low work efficiency and unguaranteed drilling position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

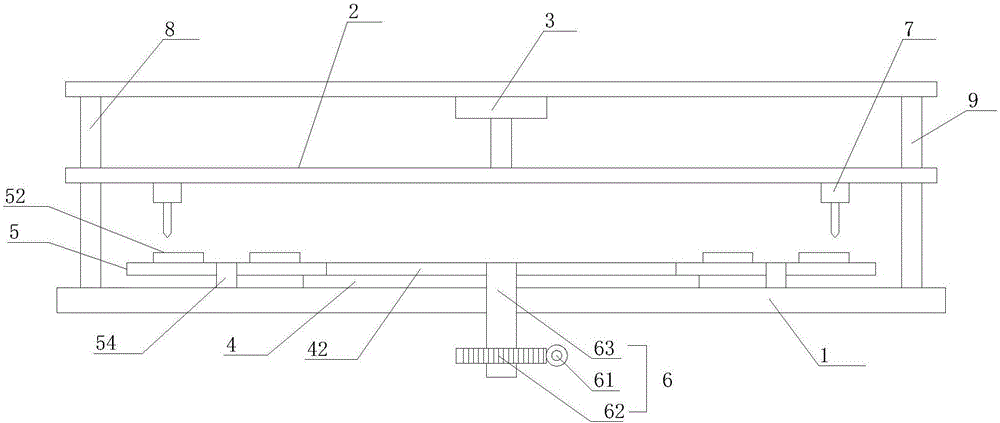

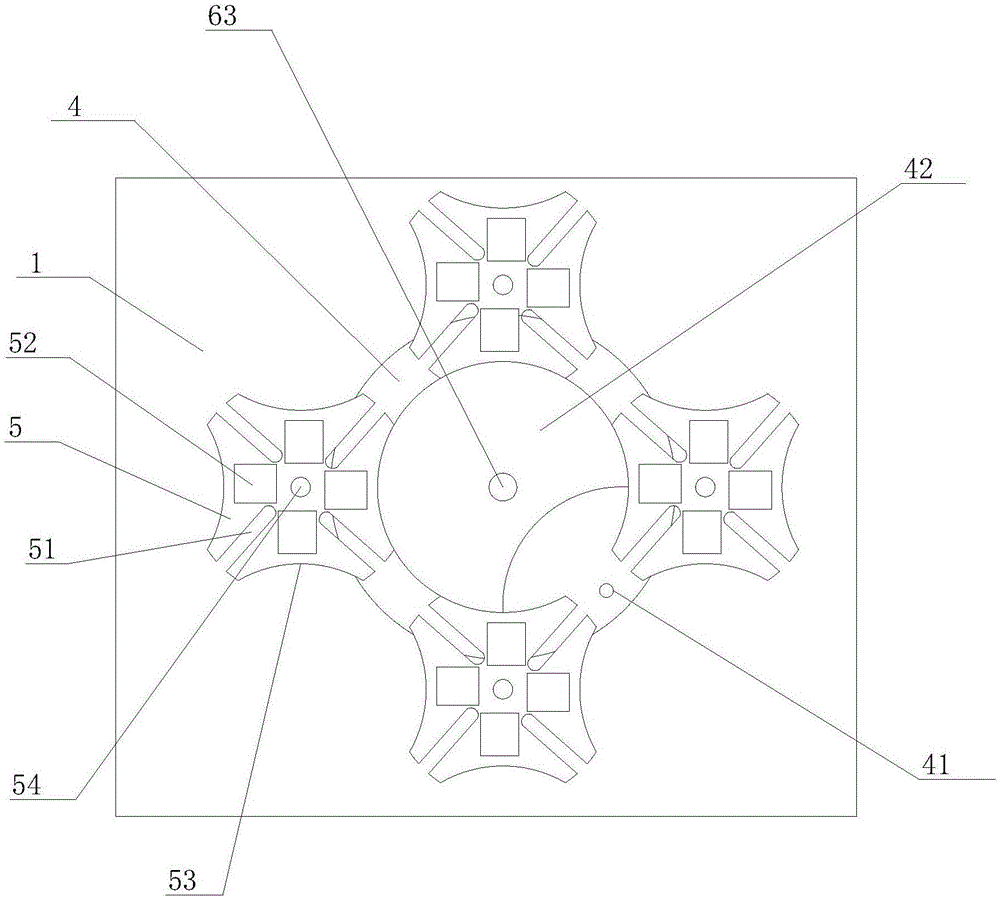

[0020] refer to figure 1 , figure 2 , the present invention proposes a continuous type charger shell automatic drilling processing equipment, including a base 1, a moving plate 2, a driving mechanism 3, a driving dial 4, N driven sheaves 5, a transmission mechanism 6, and N Drilling mechanism 7, controller, N is a natural number and N≥1, wherein:

[0021] The base 1 is arranged horizontally, the moving plate 2 is located above the base 1 and parallel to the base 1, the two ends of the base 1 are provided with a first guide column 8 and a second guide column 9, and the two ends of the moving plate 2 are respectively connected to the first guide column 8, the second guide column The two guide columns 9 are slidingly connected, and a processing area is formed between the base 1 and the moving plate 2 , and the moving plate 2 is provided with a distance measuring sensor for real-time monitoring of the distance between the moving plate 2 and the base 1 .

[0022] The driving mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com