An electron beam high-precision high-frequency deflection scanning device

A deflection scanning, high-precision technology, applied to electrode devices and related components, improving energy efficiency, improving process efficiency, etc., can solve the problems of small electron beam deflection angle, slow electron beam scanning speed, and small driving current, etc. Improve deflection scanning speed, large-scale deflection scanning, and uniform electromagnetic field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The invention provides an electron beam high-precision high-frequency deflection scanning device, and its specific implementation method is:

[0086] The electron beam high-precision high-frequency deflection scanning device includes:

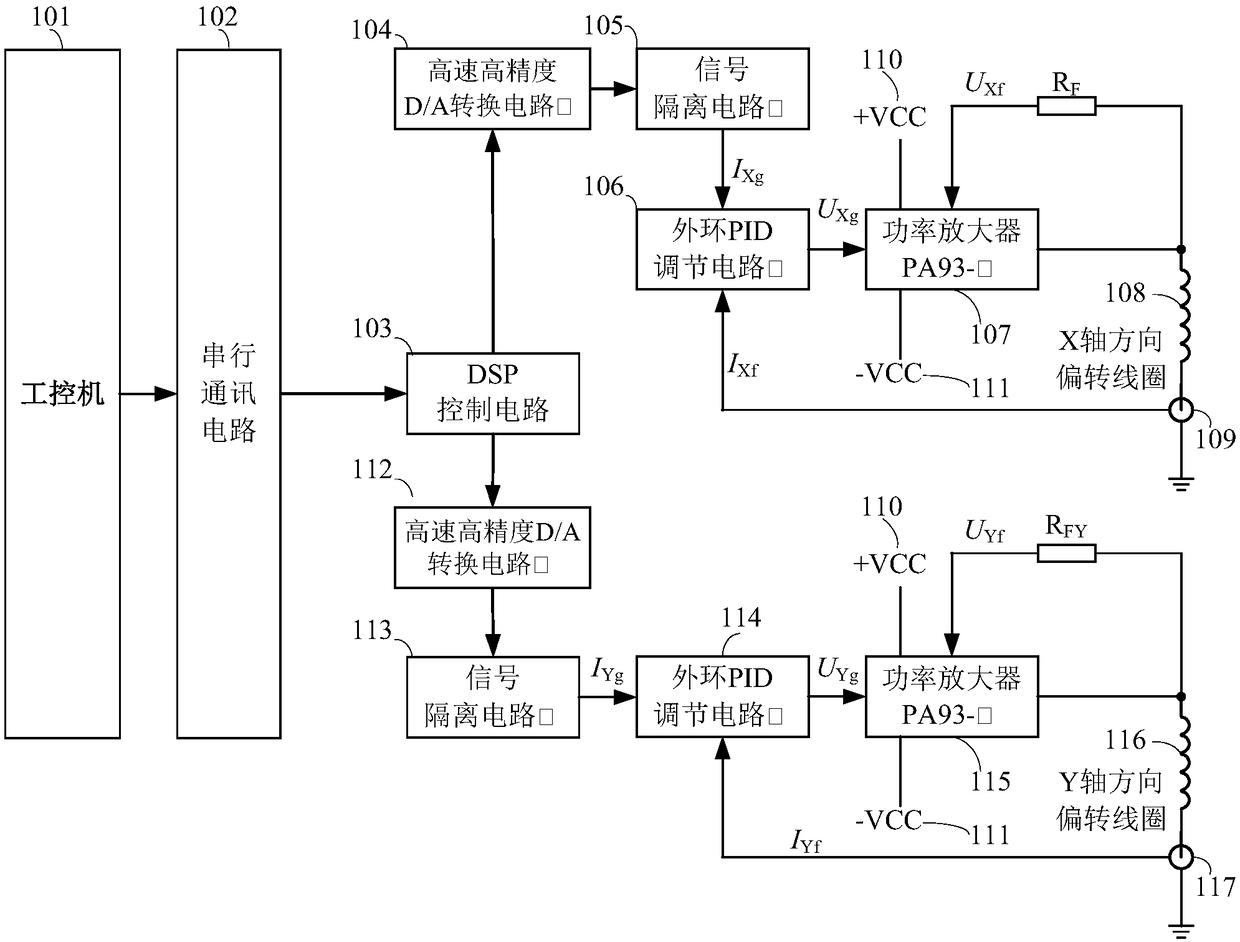

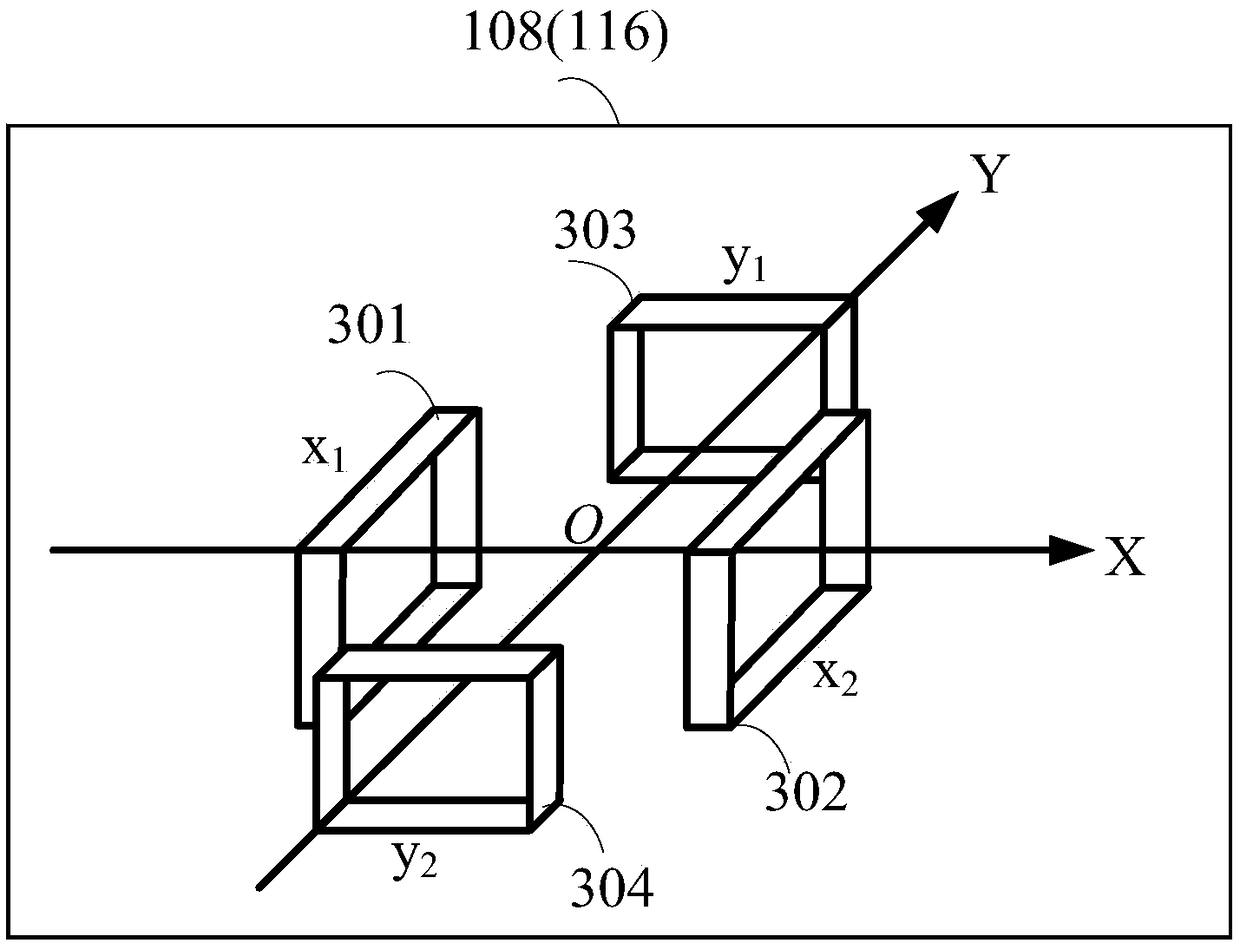

[0087] see figure 1 As shown, industrial computer 101, serial communication circuit 102, DSP control circuit 103, high-speed and high-precision D / A conversion circuit Ⅰ 104, high-speed and high-precision D / A conversion circuit Ⅱ 112, signal isolation circuit Ⅰ 105, signal isolation circuit Ⅱ 113, outer ring PID regulation circuit Ⅰ106, outer ring PID regulation circuit Ⅱ114, power amplifier PA93-Ⅰ107, power amplifier PA93-Ⅱ115, X-axis direction deflection scanning coil 108, current sensor Ⅰ109, Y-axis direction deflection scanning coil 116, current sensor Ⅱ117, +160V DC voltage source 110 and -160V DC voltage source 111. The position connection relationship between them is: the industrial computer 101 is connected to the DSP control ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com