Closed punching method for 1Cr12Ni2WMoVNb steel high-cylinder ring piece

A technology of punching and high cylinder, which is applied in the field of punching to achieve the effect of improving appearance quality, improving consistency and reducing operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] The main chemical element content (weight percentage) of the 1Cr12Ni2WMoVNb steel is: C content 0.11%~0.17%, Mn content ≤0.60%, Si content ≤0.60%, Cr content 11.00%~12.00%, Ni content 1.80 %~2.20%, W content 0.7%~1.0%, Mo content 0.80%~1.20%, V content 0.20%~0.30%, Nb content 0.15%~0.30%, P content ≤0.030%, S content The amount is ≤0.020%, and the balance is Fe.

[0016] The steps of this method are as follows:

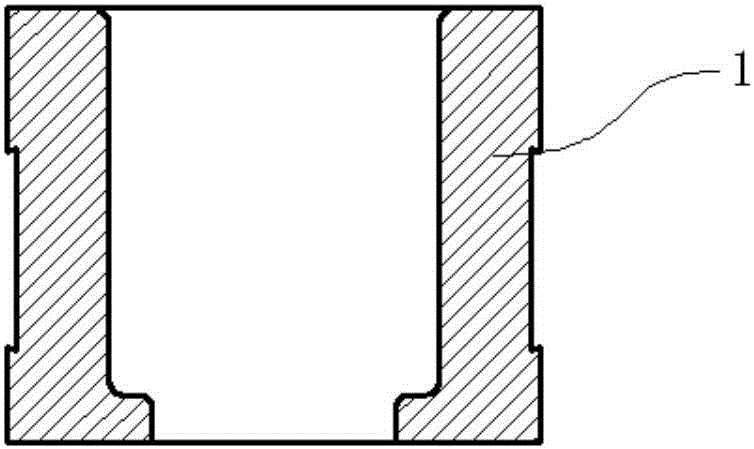

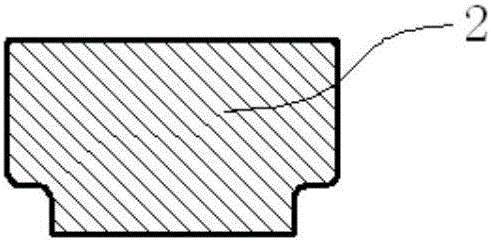

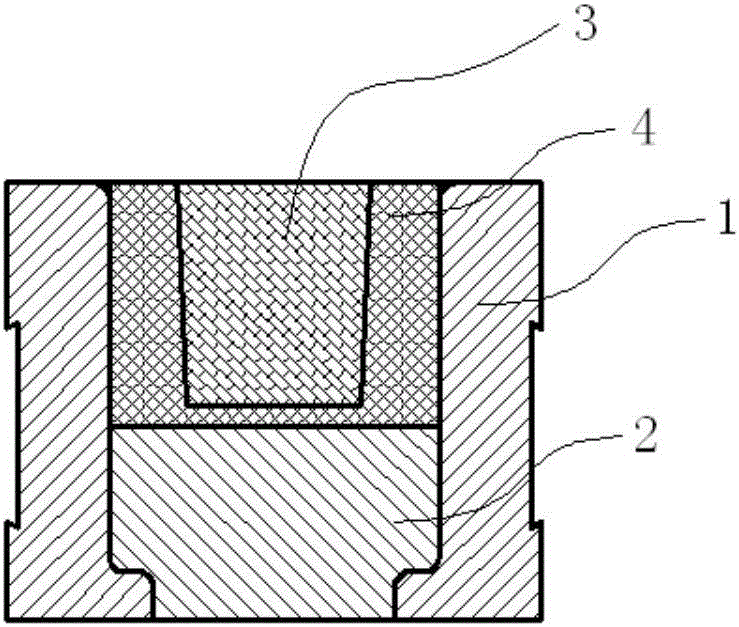

[0017] The 1Cr12Ni2WMoVNb steel is cut into bars according to certain specifications; the 1Cr12Ni2WMoVNb steel bar is heated to 1170±10℃, and the temperature is maintained at (0.4~0.5) min / mm, and the furnace temperature is ≤750℃; after the heat through, the 1Cr12Ni2WMoVNb steel The bar is placed on the press, and the forging hammer is driven to upset the 1Cr12Ni2WMoVNb steel bar to a predetermined size; the upsetting 1Cr12Ni2WMoVNb steel blank 4 is put into the punching die 1, and placed together under the press, the punching die The outer wall of 1 has a dovetai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com