Die-casting die and method for delay ejection of lateral die sinking

A die-casting mold and ejection technology, which is applied in the field of die-casting molds, can solve the problems of inconvenient mold opening, inability to produce, and different angles, and achieve the effects of simple structure, reliable operation, and quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Specific steps are as follows:

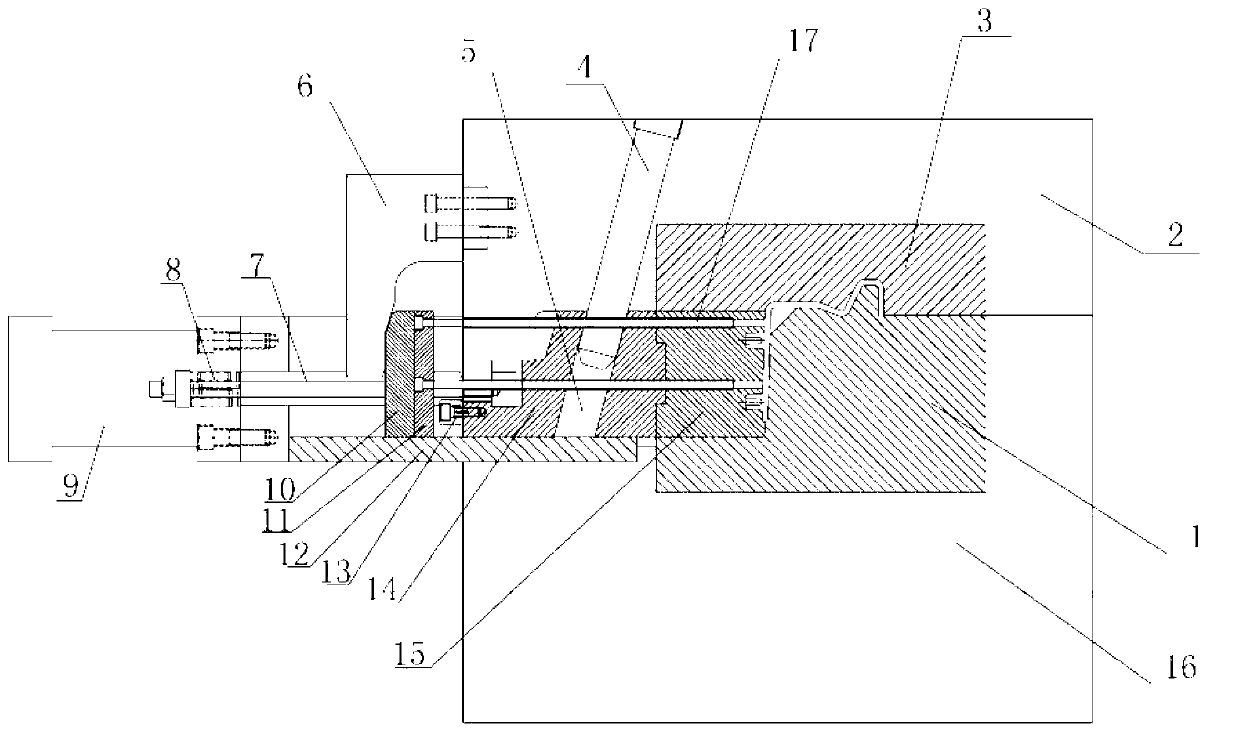

[0025] (a) if figure 1 As shown, the mold die-casting pouring and cooling are completed. At this time, the inner side of the lower end of the push plate locking block 6 withstands the left side of the thimble push plate 10, and then the movable mold 3 and the fixed mold are separated by the toggle mold opening and closing mechanism of the die-casting machine. 1. At the same time as the mold is opened, the oil cylinder 9 moves, and the slider 15 is pulled by the slider seat 14 to slide to the left on the friction block 12;

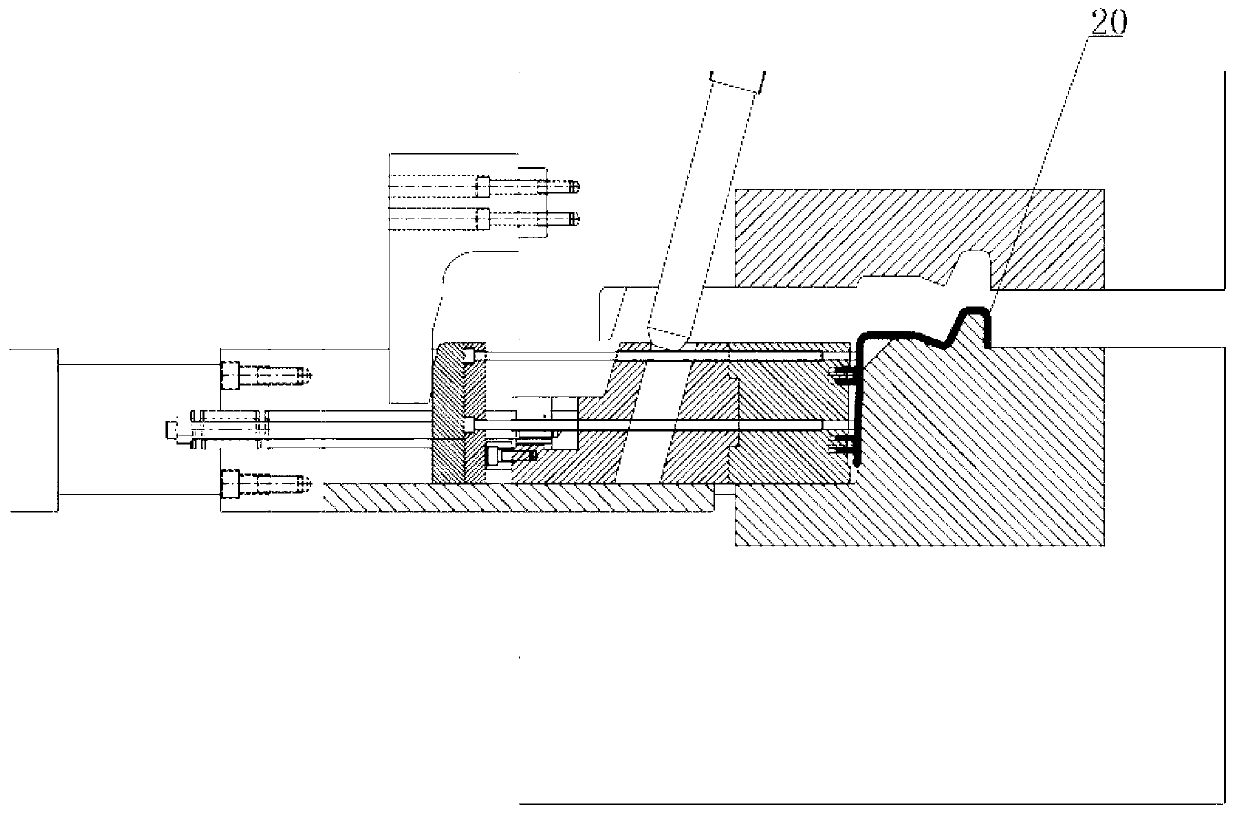

[0026] (b) if figure 2 As shown, the rising of the movable template 2 is carried out simultaneously with the action of the oil cylinder 9, and the inclined guide post 4 slides in the inclined guide hole 5. When the slider seat 14 slides to the limit block 13 and pushes against the thimble fixing plate 11, it cannot slide. , the thimble 17 has partially separated the workpiece 20 from the slider 15;

[0027] (c) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com